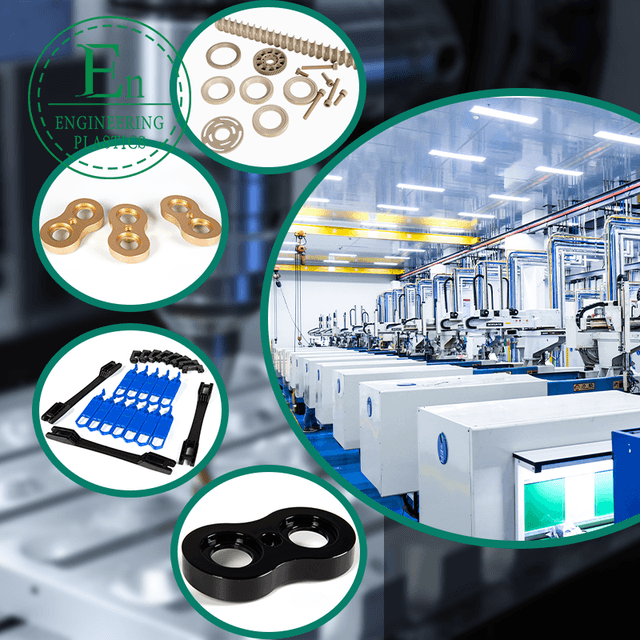

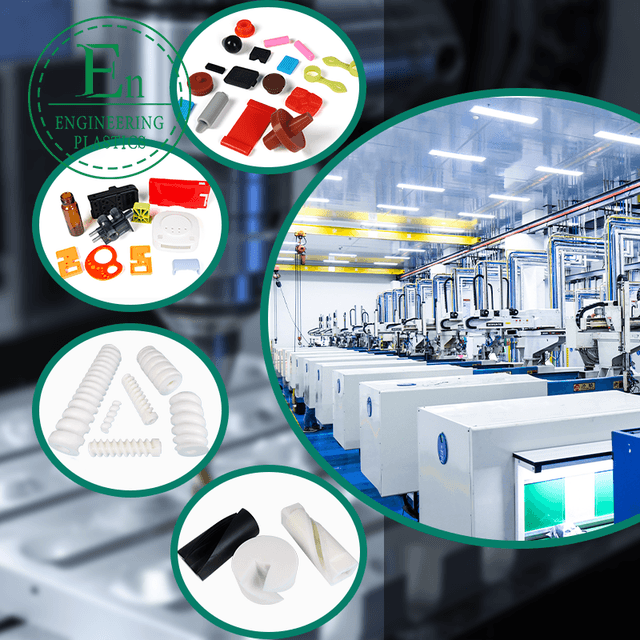

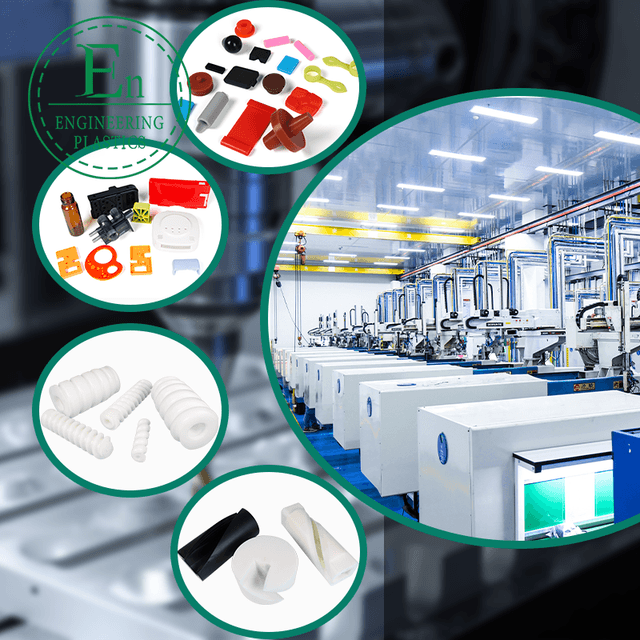

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

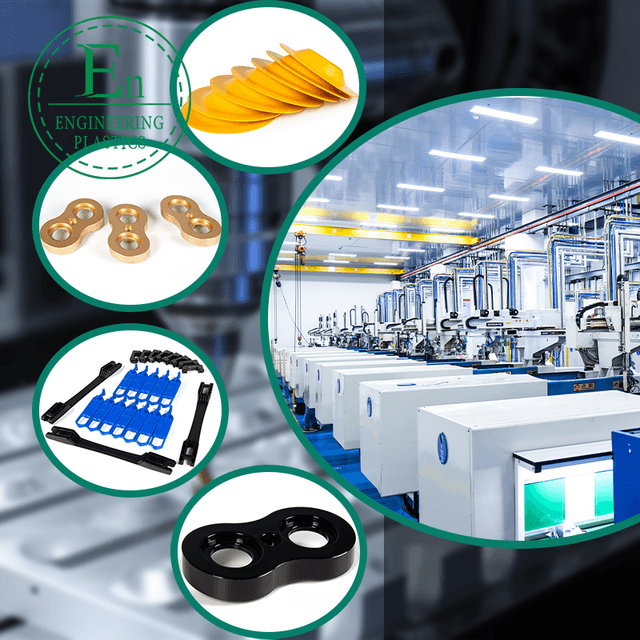

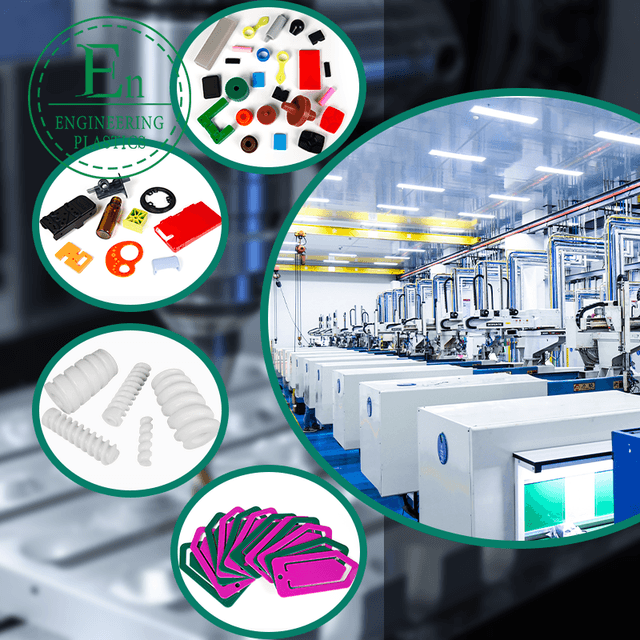

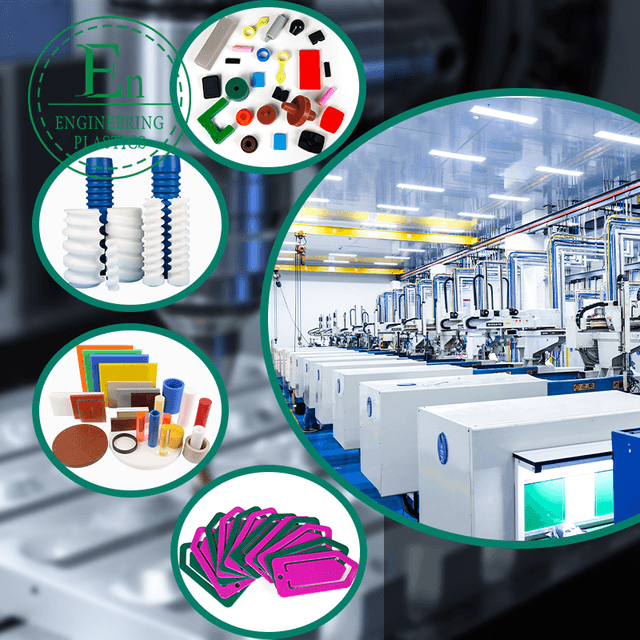

In the vibrant world of toy manufacturing, molds for plastic toys stand as the cornerstone of creativity and precision. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting high-quality molds for plastic toys that bring imaginative designs to life. With our state-of-the-art production facility equipped with cutting-edge machinery, we ensure every mold delivers exceptional accuracy and efficiency. Our team of senior engineers, boasting 15-25 years of expertise, understands the unique demands of toy production, from intricate shapes to vibrant colors. Whether you're developing action figures, building blocks, or educational playsets, our molds for plastic toys are engineered for durability and seamless performance, helping manufacturers achieve consistent results in every run.

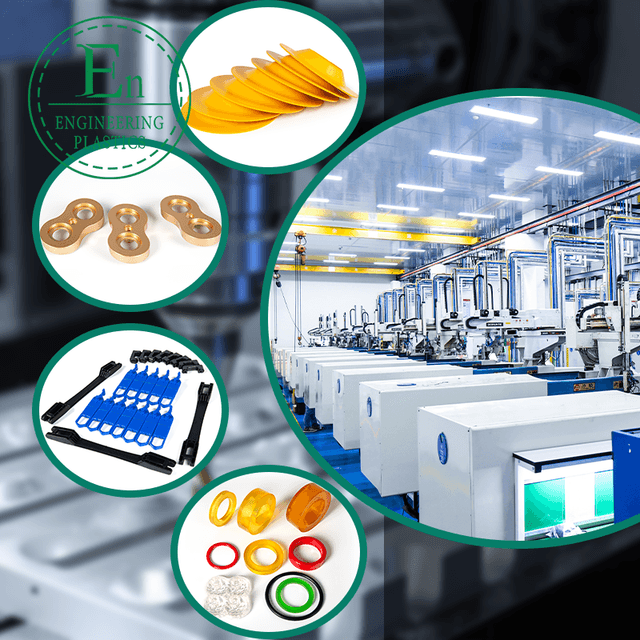

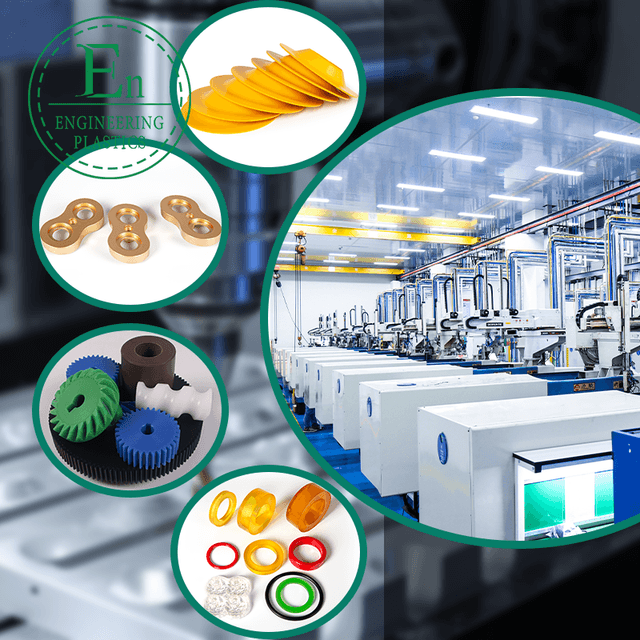

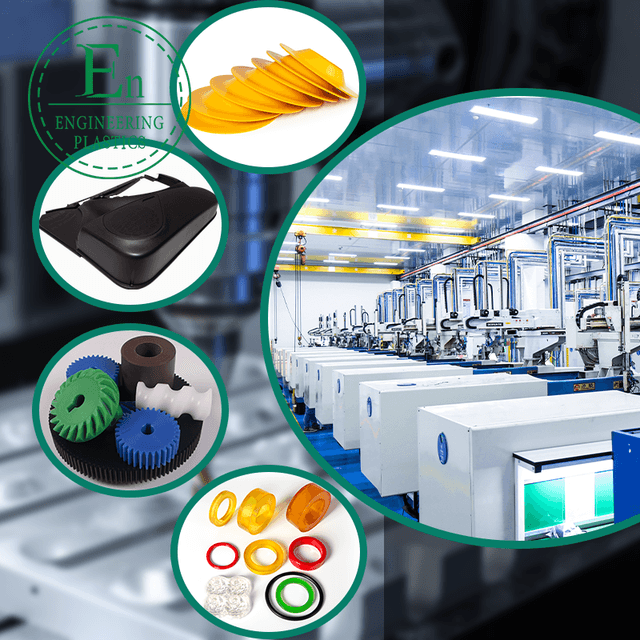

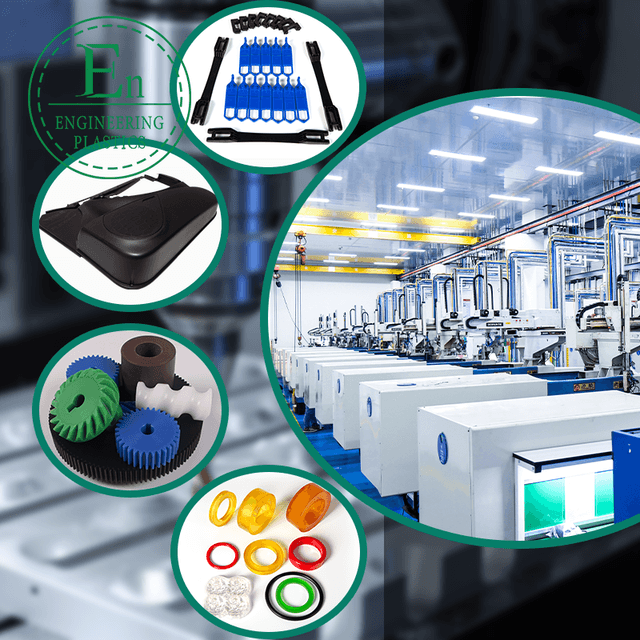

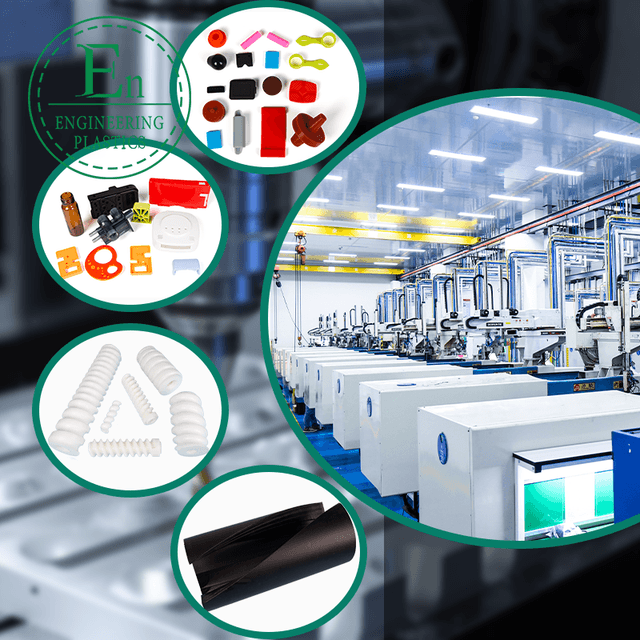

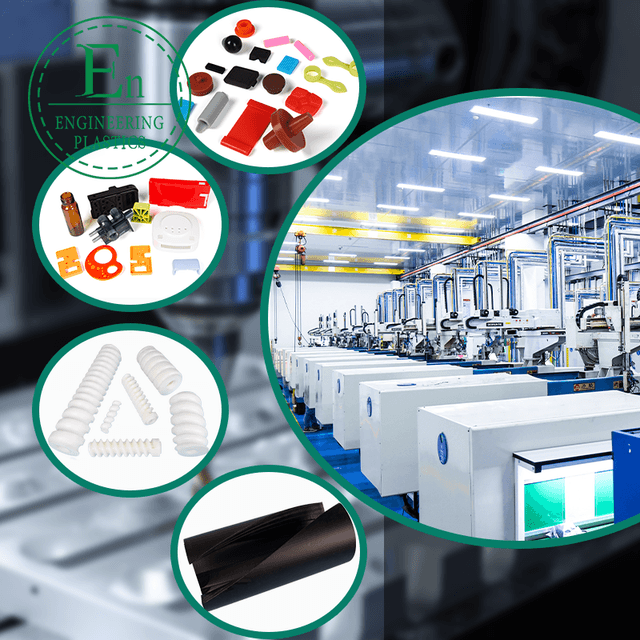

Delving deeper into our offerings, our toy mold plastic solutions are tailored for versatility across various production scales. We employ advanced materials like ABS and Nylon to create robust toy mold plastic components that withstand the rigors of injection molding processes. For businesses seeking flexibility without compromising on quality, our low volume injection molding services are a game-changer. This approach allows for small-batch production, ideal for prototyping new toy lines or customizing limited-edition items. Imagine producing a series of eco-friendly puzzles or interactive gadgets with minimal waste—our low volume injection molding minimizes upfront costs while maximizing design freedom. Our precision-machined parts ensure that each toy mold plastic iteration captures fine details, from textured surfaces to interlocking mechanisms, making your products stand out in competitive markets.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our commitment to personalized customization and comprehensive research and development. We don't just build molds for plastic toys; we partner with clients to innovate solutions that align with global standards. Exporting to the USA, UK, Canada, Germany, and beyond, we've earned a stellar reputation for reliability and excellence. Our portfolio includes a diverse array of engineering plastic products, but our focus on toy applications ensures child-safe, vibrant components that meet stringent safety regulations. For instance, our vibrant plastic components, highlighted in our facility showcases, come in numerous colors perfect for eye-catching toys. Coupled with flexible plastic tubing for movable parts, these elements enhance play value and longevity.

Embracing low volume injection molding opens doors for startups and established brands alike to test market responses swiftly. Our engineers collaborate closely to refine toy mold plastic designs, incorporating feedback for optimal outcomes. This iterative process reduces time-to-market and fosters innovation, whether it's for holiday specials or year-round favorites. With materials like PEEK and PTFE for specialized needs, we guarantee that molds for plastic toys perform reliably under high-pressure conditions. Trust our global expertise to elevate your production—contact us today to discuss how our tailored molds can transform your toy manufacturing vision into reality. As we continue to drive progress in the industry, Guangdong Engineering Plastics Industries Group Co., Ltd. remains your premier partner for precision and passion in every plastic creation.