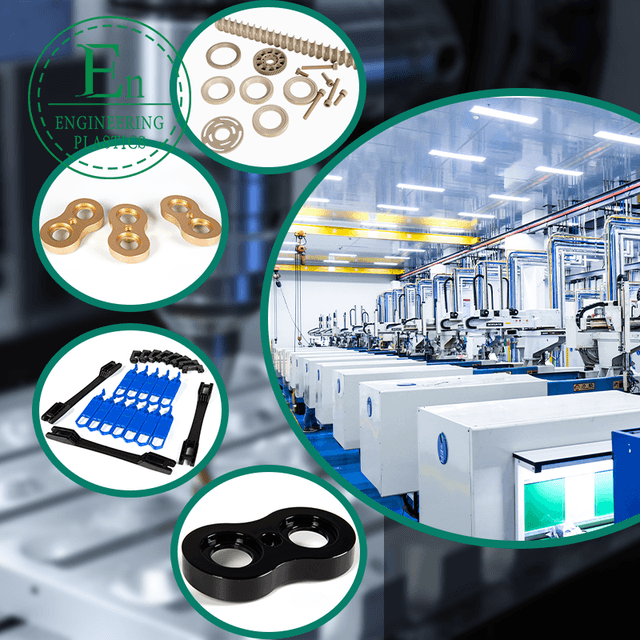

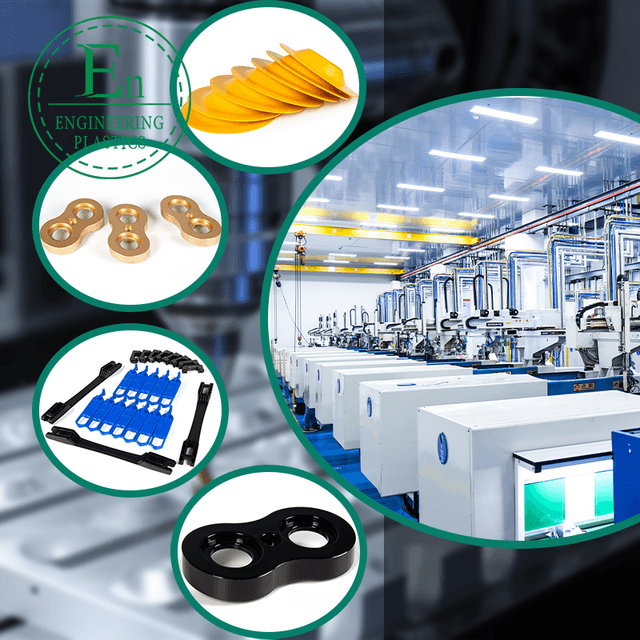

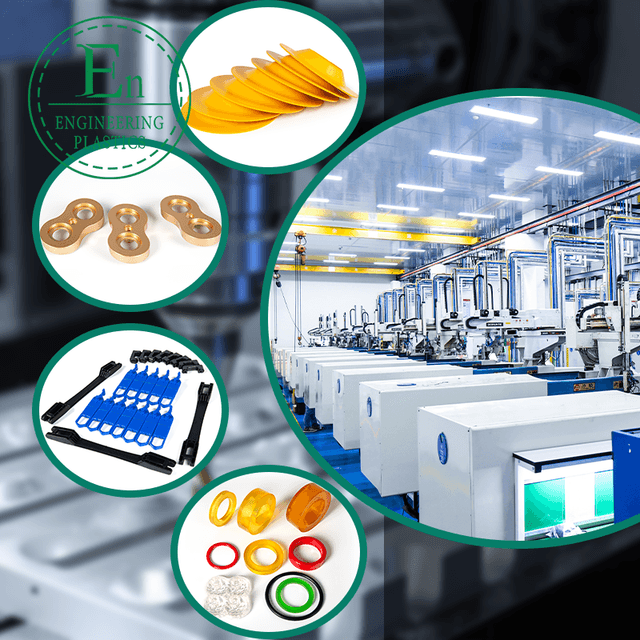

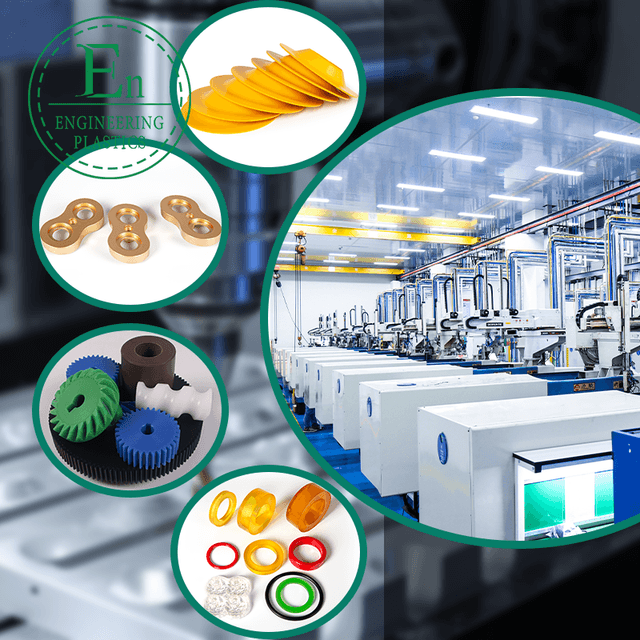

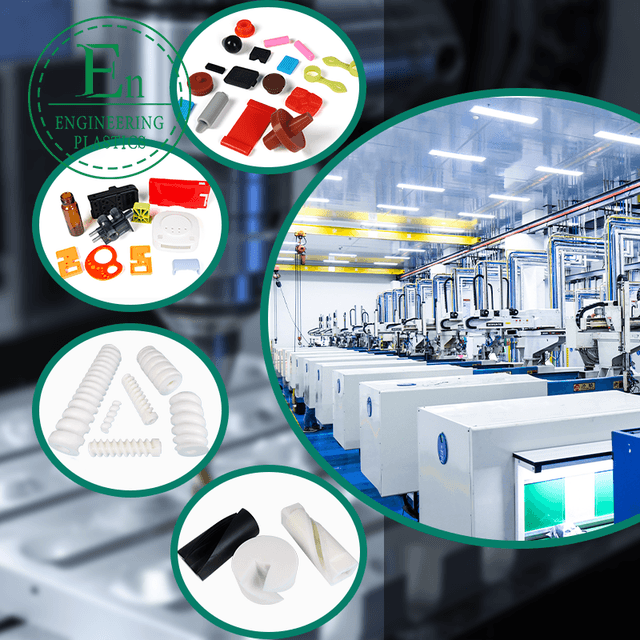

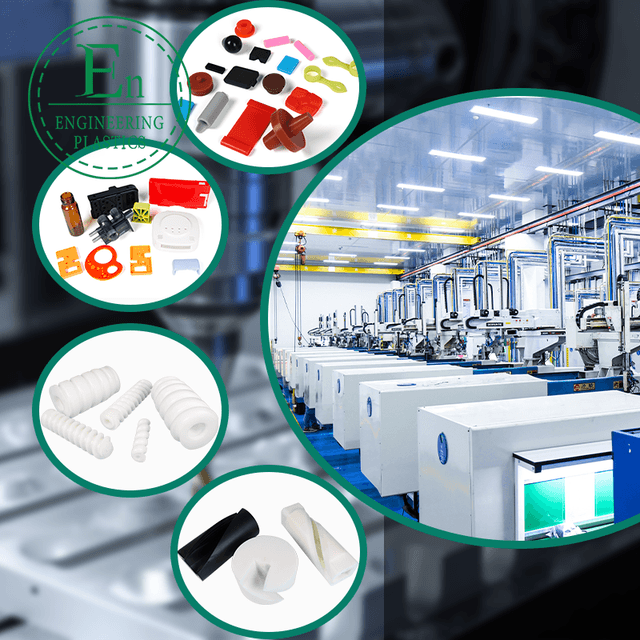

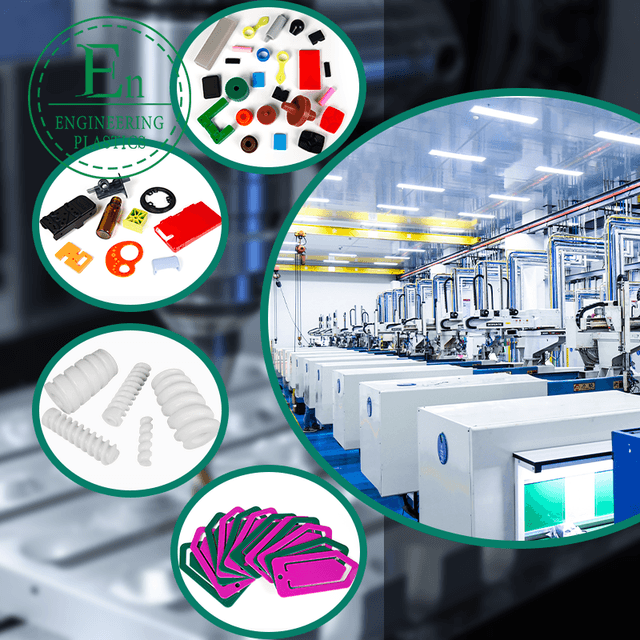

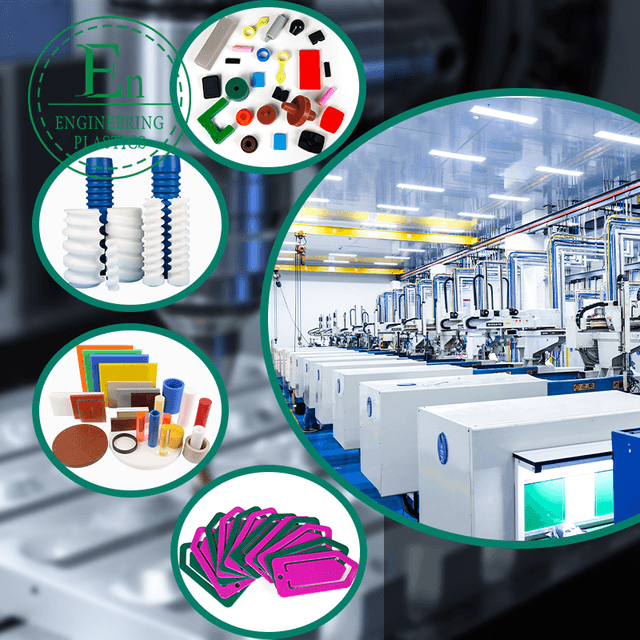

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

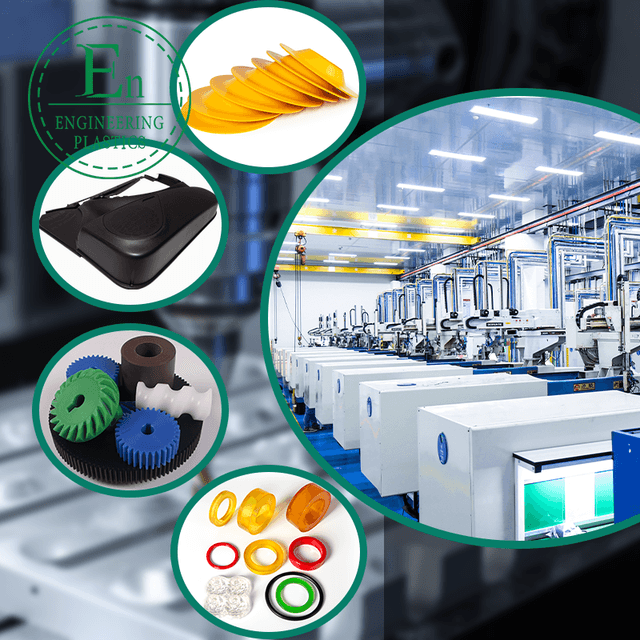

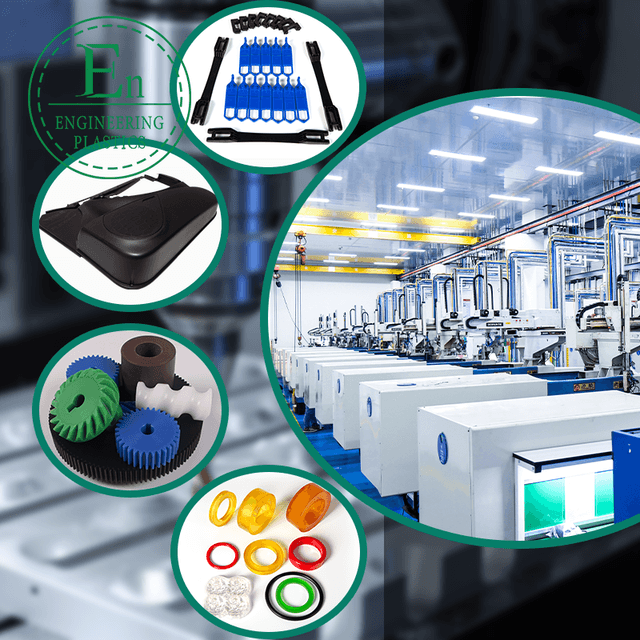

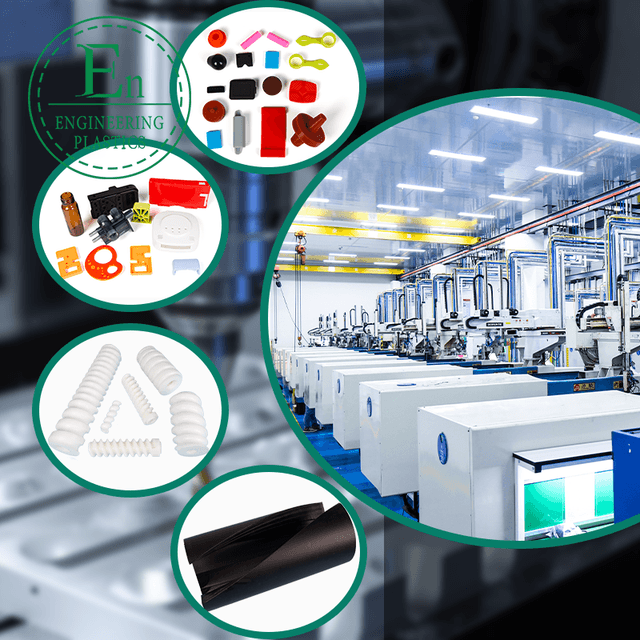

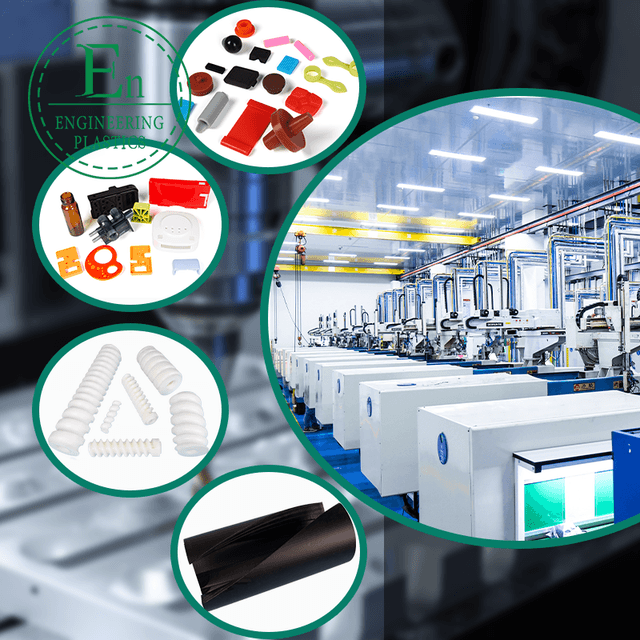

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, bottle molding stands as a cornerstone process for creating high-quality plastic containers essential for packaging solutions across industries. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage our expertise in bottle molding to deliver innovative, durable products that meet the rigorous demands of modern production lines. Our advanced techniques ensure that every molded bottle achieves superior clarity, strength, and uniformity, making it ideal for beverages, pharmaceuticals, and cosmetics. With a team of senior engineers boasting 15-25 years of experience, we specialize in customizing bottle molding processes to fit unique specifications, drawing on high-performance engineering plastics like PET and HDPE for optimal results.

Complementing our bottle molding capabilities is our expertise in bottle cap mold design and production. A bottle cap mold is crucial for ensuring a secure, leak-proof seal that protects contents and enhances user experience. Our bottle cap molds are precision-engineered using state-of-the-art CNC machining and injection molding technologies, allowing for intricate details and high-volume output without compromising quality. Whether you need tamper-evident caps or ergonomic designs, our facility produces bottle cap molds from robust materials that withstand repeated cycles, minimizing downtime and maximizing efficiency. Serving clients from the USA to Germany, we export these specialized molds, helping global brands maintain consistency in their packaging lines while adhering to international standards.

For applications requiring exceptional optical properties and structural integrity, pmma injection molding is a key service we offer alongside our bottle molding solutions. PMMA, or acrylic, injection molding enables the creation of crystal-clear components that rival glass in transparency but surpass it in impact resistance and lightweight design. At Guangdong Engineering Plastics Industries Group, we utilize PMMA injection molding to fabricate precise parts such as transparent bottle necks or protective casings, ensuring seamless integration with our broader plastic product lineup including gears, seals, and bearings made from materials like PEEK, Nylon, and PTFE. This process is particularly valuable in industries where aesthetics and functionality intersect, providing customized solutions that elevate product performance in demanding environments.

Our commitment to innovation extends beyond standard bottle molding and related processes; we provide comprehensive design, research, and development support to tailor solutions for bespoke needs. By combining bottle cap mold precision with the versatility of pmma injection molding, we help clients achieve cost-effective, high-reliability packaging systems. From initial prototyping to full-scale production, our 25,000-square-meter facility equipped with cutting-edge machinery guarantees that every project benefits from our global reputation for quality and reliability. Choosing Guangdong Engineering Plastics means partnering with a leader in engineering plastics, where bottle molding evolves into a strategic advantage for your business, fostering efficiency, sustainability, and market competitiveness in an ever-evolving industrial landscape.