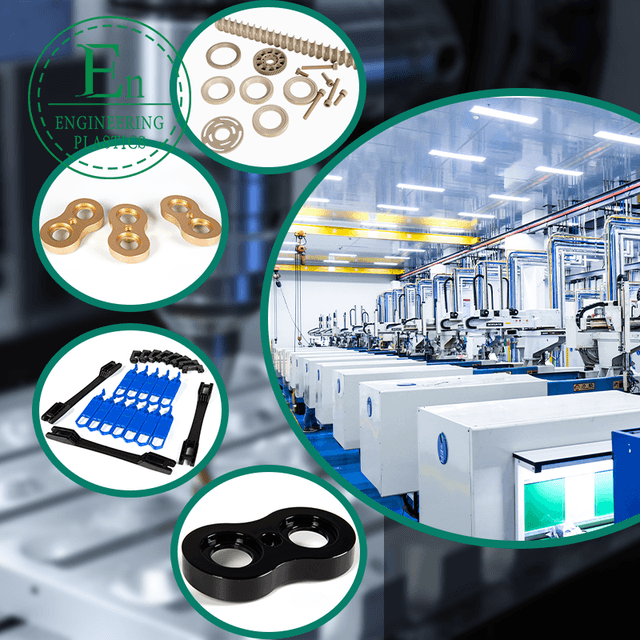

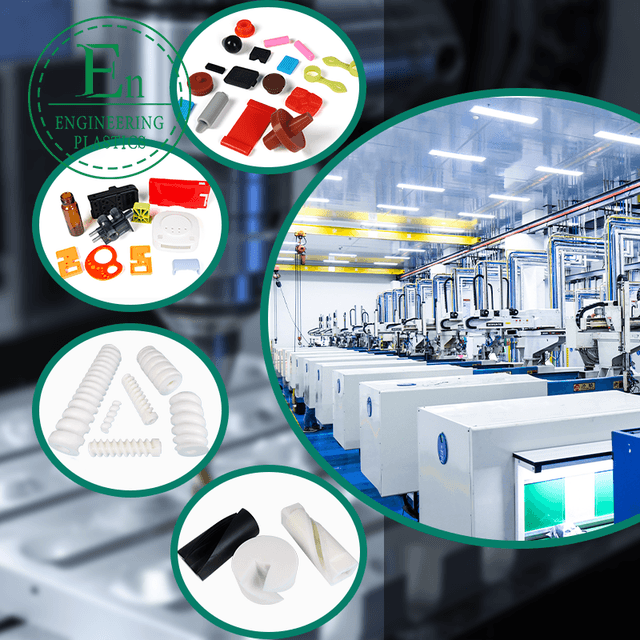

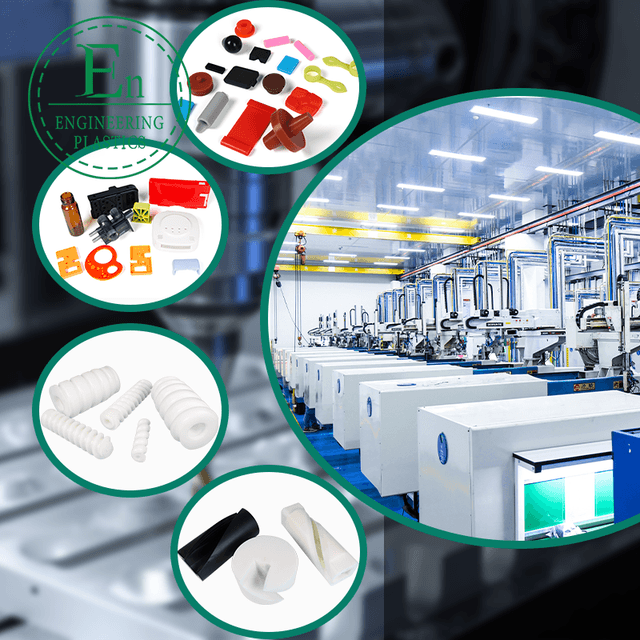

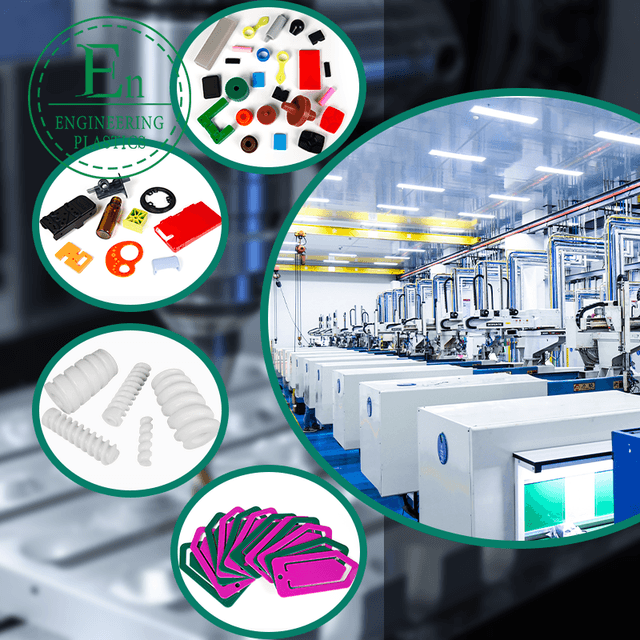

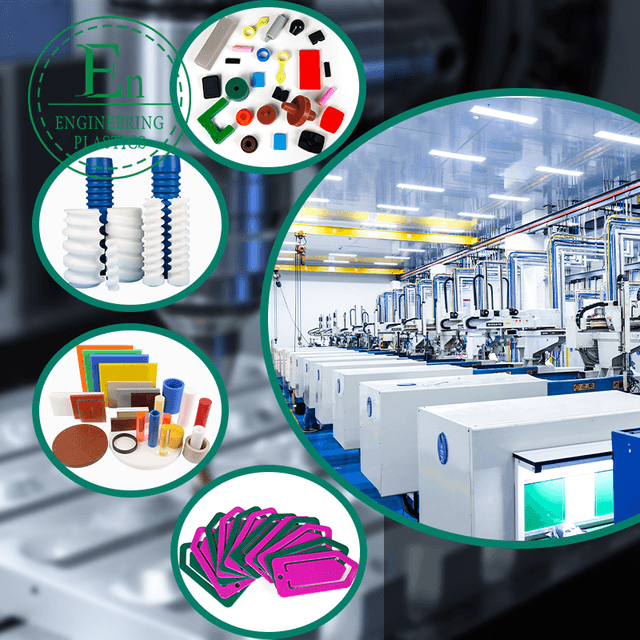

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Discover the excellence of the car bumper mold from Guangdong Engineering Plastics Industries Group Co., Ltd., a leader in precision engineering solutions. With over 15 years of collective expertise from our senior engineers, we craft molds that meet the demanding standards of the automotive industry. Our car bumper mold is designed for high-volume production, ensuring durability and flawless replication of complex bumper designs. Whether you're manufacturing vehicles for rugged terrains or sleek urban models, this mold integrates seamlessly into your production line, leveraging advanced materials like ABS and Nylon for superior strength and impact resistance. At Guangdong Engineering Plastics, we prioritize innovation to deliver molds that reduce cycle times and minimize defects, empowering your business to stay ahead in a competitive market.

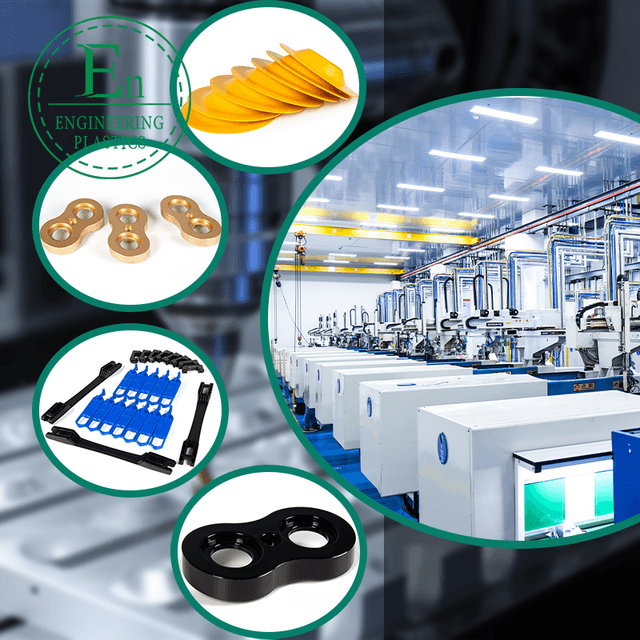

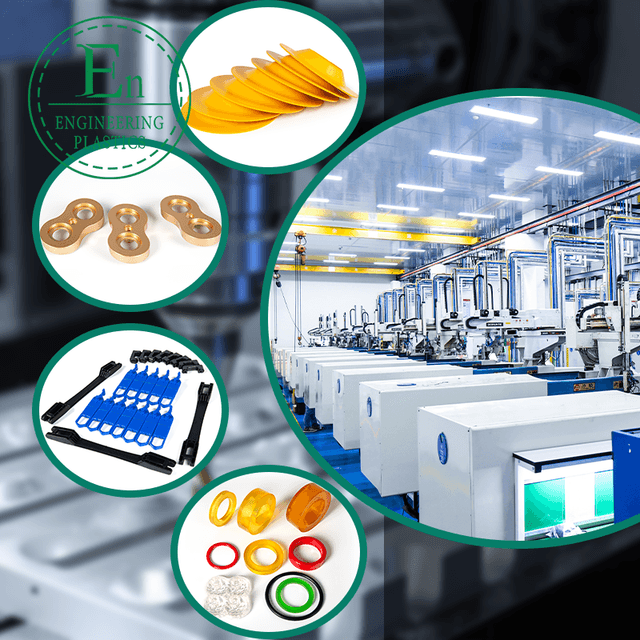

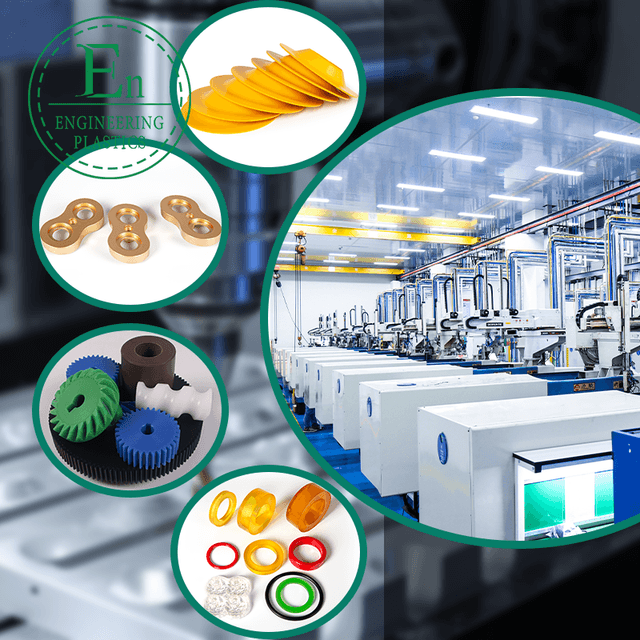

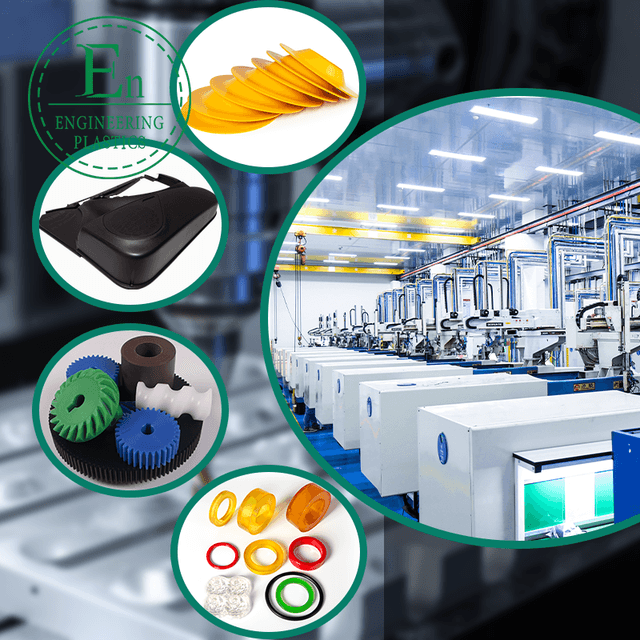

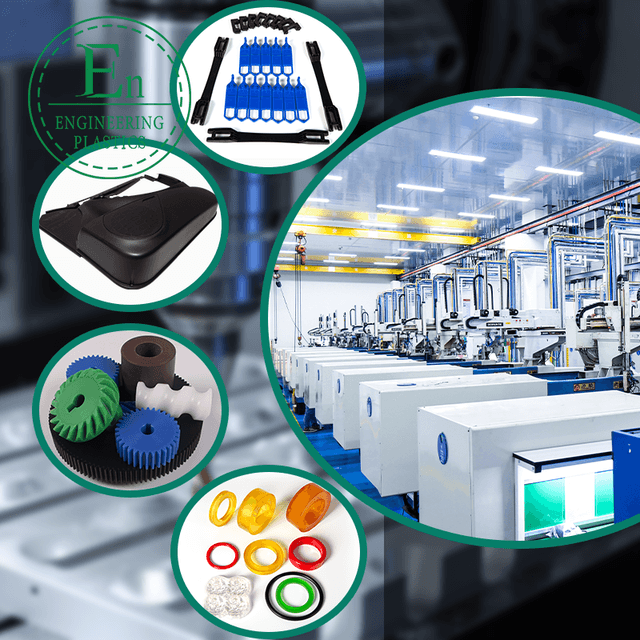

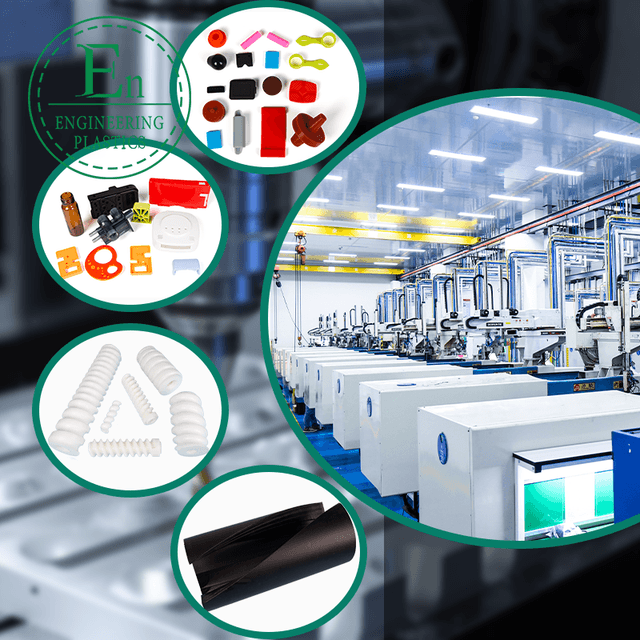

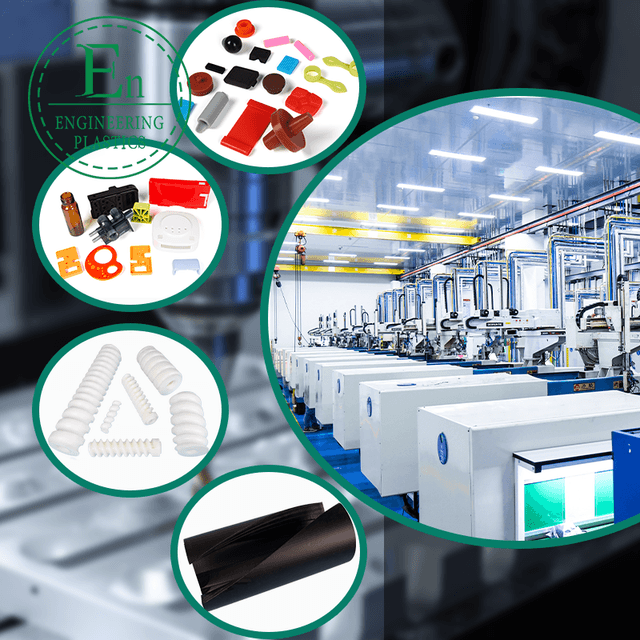

Building on our core offerings, our plastic container mold extends the versatility of our molding technology to packaging and storage solutions. This mold is engineered for precision shaping of various container sizes, ideal for food, pharmaceutical, and industrial applications. Our team at Guangdong Engineering Plastics Industries Group Co., Ltd. utilizes cutting-edge techniques to produce molds that withstand high pressures and temperatures, ensuring consistent quality output. Complementing this, our rod mold specializes in creating cylindrical components essential for mechanical assemblies, from automotive shafts to structural supports. With materials such as PEEK and PTFE, these molds guarantee rods that offer exceptional wear resistance and longevity. Our commitment to personalized customization means we tailor each mold to your exact specifications, serving clients across the USA, UK, Canada, and Germany with unmatched reliability.

In the realm of high-performance components, our car bumper mold stands out for its role in enhancing vehicle safety and aesthetics. It facilitates the creation of bumpers that absorb shocks effectively, thanks to the robust engineering plastics we employ. Similarly, the plastic container mold supports sustainable practices by enabling recyclable designs that reduce material waste. Our rod mold, meanwhile, finds applications in gears, pulleys, and bearings, showcasing our broad expertise in engineering plastics like PPS and Nylon. Guangdong Engineering Plastics Industries Group Co., Ltd. prides itself on a state-of-the-art facility where research and development drive continuous improvement. This ensures that every product, from vibrant O-rings to blue electrical connectors, aligns with global standards for performance and efficiency.

Our global reputation is built on delivering comprehensive solutions that go beyond mere manufacturing. For instance, the car bumper mold incorporates features for easy demolding and minimal flash, streamlining your operations. The plastic container mold offers modular designs for quick adaptations, while the rod mold ensures precise tolerances for intricate parts. With exports to diverse markets, we understand the nuances of international regulations and client needs. Whether you're integrating yellow plastic spacers for stability or bronze gear components for heavy-duty use, our molds provide the foundation for success. At Guangdong Engineering Plastics Industries Group Co., Ltd., we are dedicated to fostering long-term partnerships through quality, innovation, and responsive service, helping your projects thrive in any industry.