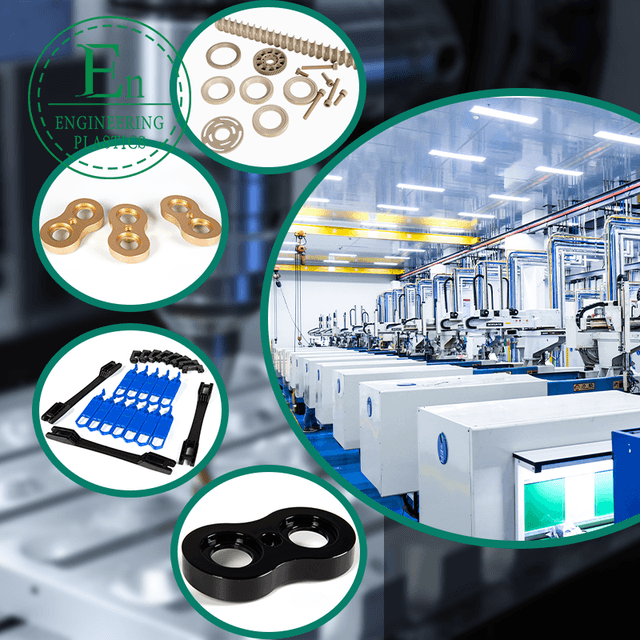

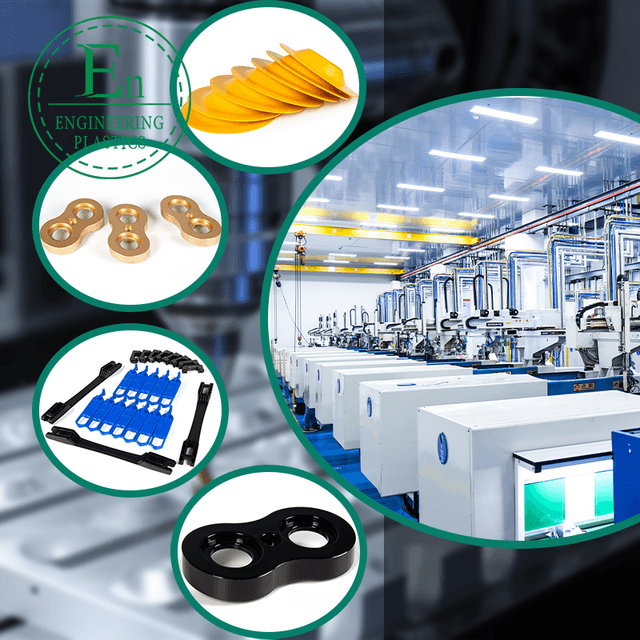

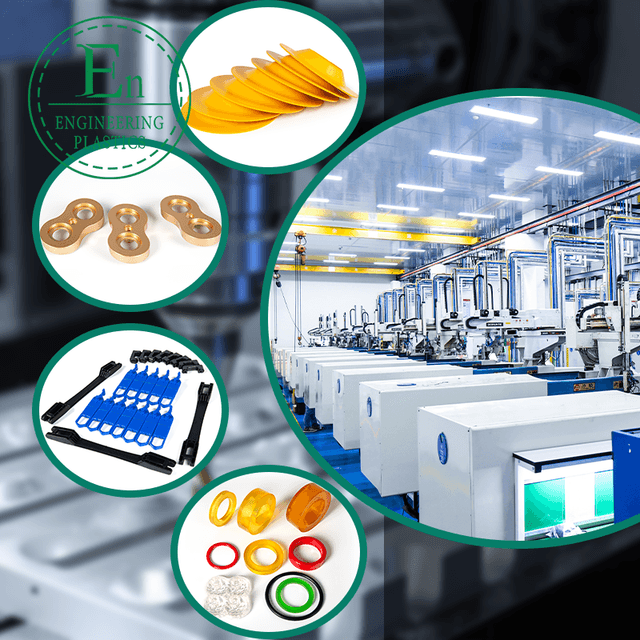

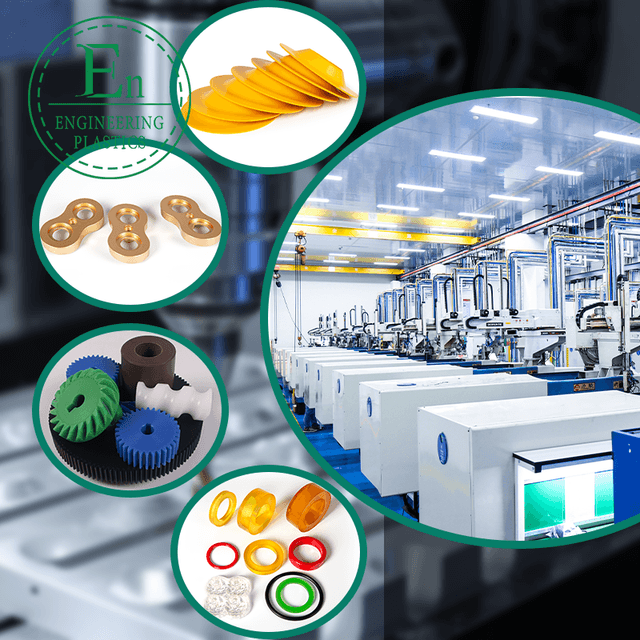

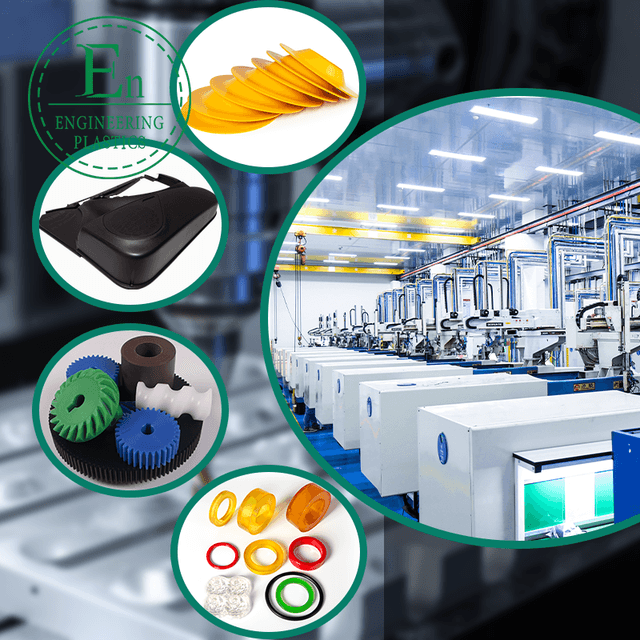

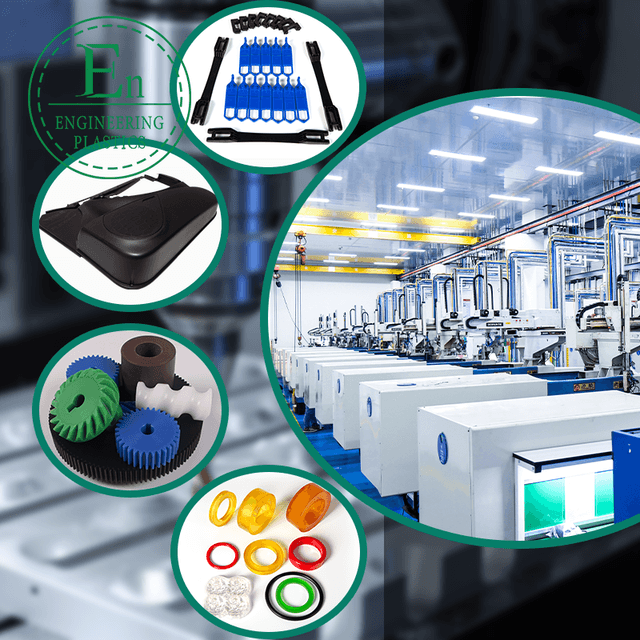

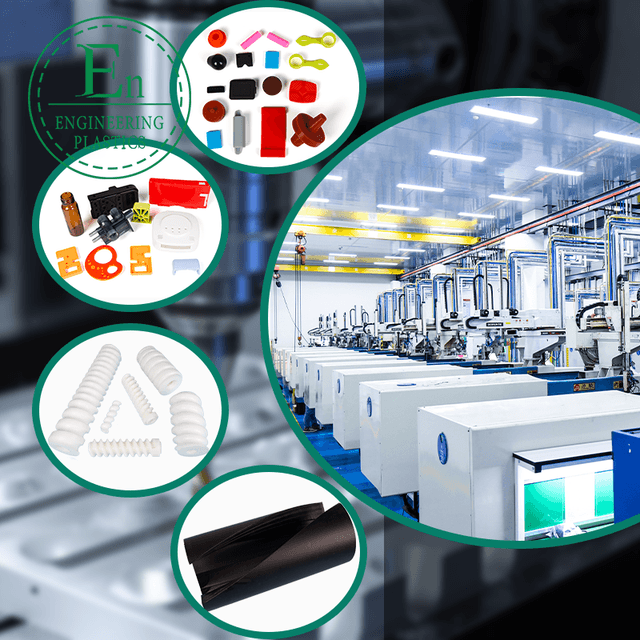

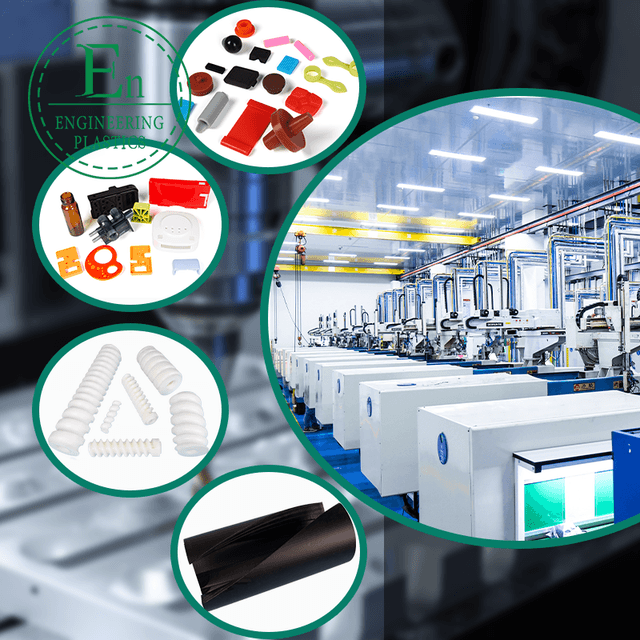

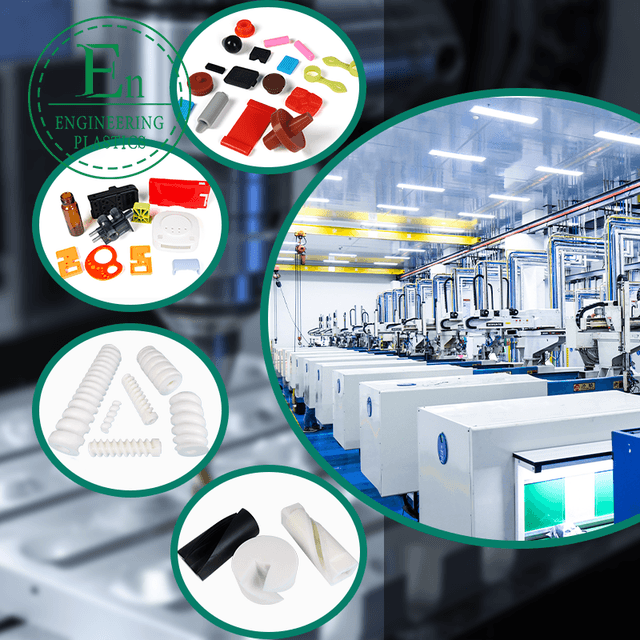

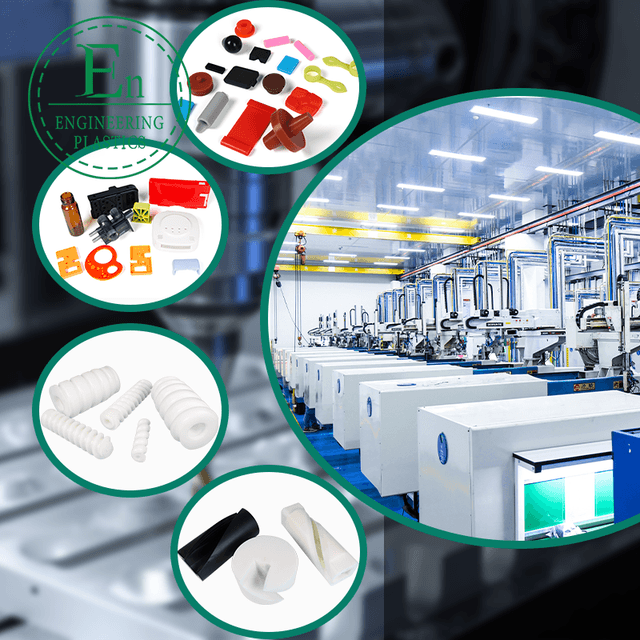

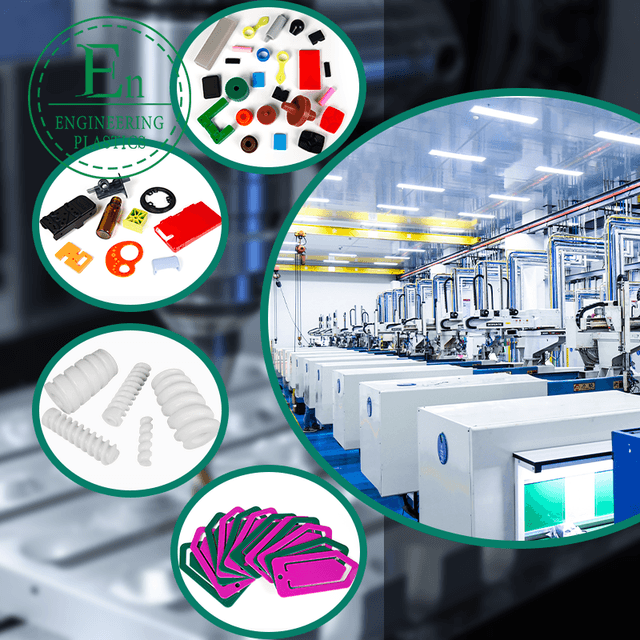

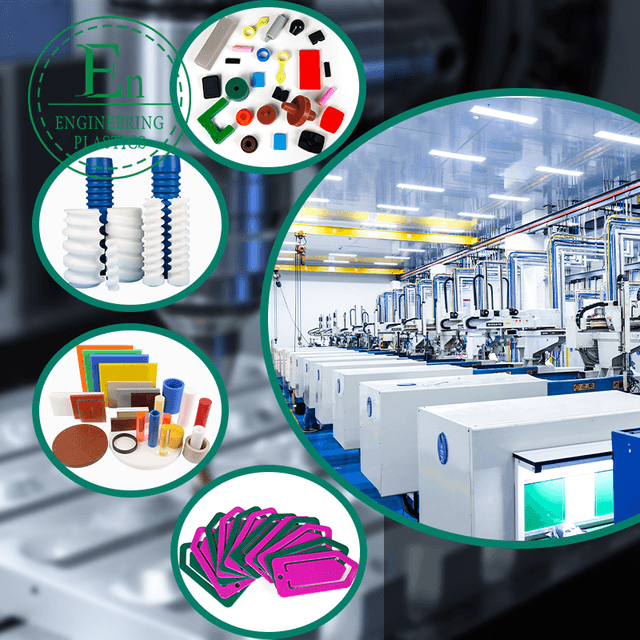

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Discover the innovation behind our premium injection molded chair, a perfect blend of comfort, durability, and modern design from Guangdong Engineering Plastics Industries Group Co., Ltd. As a leader in engineering plastics with over 15-25 years of expertise from our senior engineers, we craft these chairs using advanced techniques that ensure precision and reliability. Our state-of-the-art facility produces high-performance components that cater to diverse needs, making the injection molded chair an ideal choice for offices, homes, and public spaces. With materials like ABS and Nylon, each chair is built to withstand daily wear while offering ergonomic support.

Delving into the manufacturing process, our injection molded chair benefits from cutting-edge carbon fiber injection molding technology. This method integrates carbon fiber reinforcements into the plastic structure, enhancing strength without adding unnecessary weight. The result is a lightweight yet robust seating solution that resists impacts and supports up to 300 pounds comfortably. We also utilize cost-effective approaches with our cheap plastic injection mould designs, allowing us to deliver high-quality products at competitive prices. Our team's comprehensive design and research capabilities mean every detail, from the curved backrest to the stable base, is optimized for user satisfaction and longevity. Whether for commercial or residential use, these chairs exemplify our commitment to innovation and customer-centric engineering.

What sets our injection molded chair apart is the versatility it brings to any setting. Available in a range of colors and finishes, including sleek black and crisp white variants, the chairs can be customized to match your aesthetic preferences. The carbon fiber injection molding process ensures superior resistance to chemicals and environmental factors, making them suitable for high-traffic areas like cafeterias or waiting rooms. Our cheap plastic injection mould strategy further allows for scalable production, enabling quick turnaround times for bulk orders. Backed by our global reputation, with exports to the USA, UK, Canada, Germany, and more, Guangdong Engineering Plastics Industries Group Co., Ltd. guarantees products that meet international standards. Clients appreciate the seamless integration of components like reinforced legs and adjustable heights, all molded with precision to eliminate weak points.

In addition to functionality, our injection molded chair prioritizes sustainability. By employing efficient cheap plastic injection mould techniques, we minimize material waste and energy consumption during production. The use of recyclable engineering plastics such as PEEK and PTFE in select models underscores our eco-friendly approach without compromising on performance. Imagine outfitting your workspace with chairs that not only look professional but also contribute to a greener future. Our experienced team provides personalized consultations, ensuring the final product aligns perfectly with your specifications. From initial prototyping to full-scale manufacturing, we handle every step with the utmost care.

Ultimately, choosing an injection molded chair from our collection means investing in quality that lasts. With carbon fiber injection molding for enhanced durability and affordable cheap plastic injection mould production for accessibility, these chairs represent the pinnacle of modern furniture engineering. Guangdong Engineering Plastics Industries Group Co., Ltd. invites you to experience the difference our expertise makes. Contact us today to explore how our innovative solutions can elevate your space, backed by a legacy of excellence serving clients worldwide.