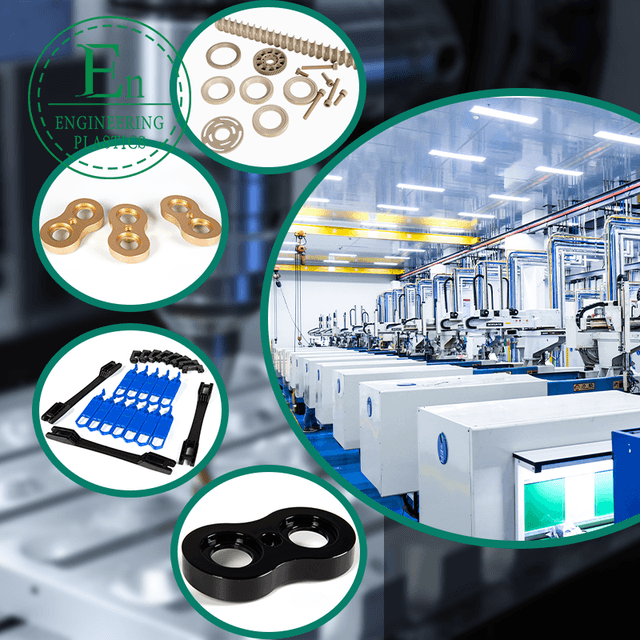

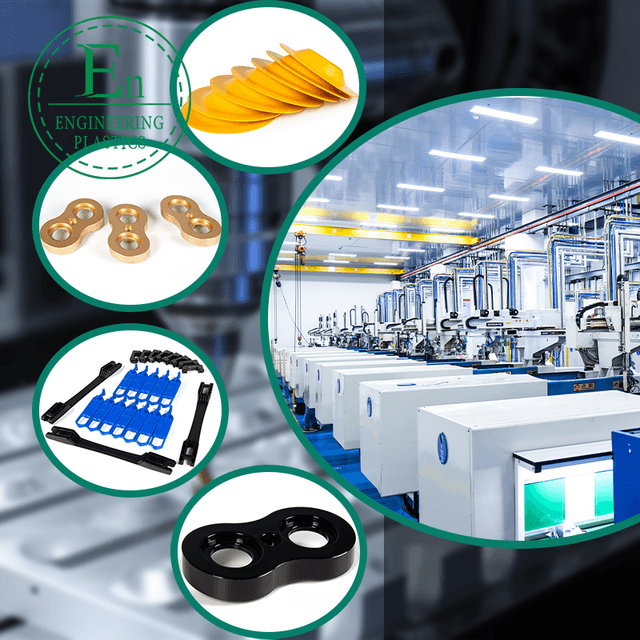

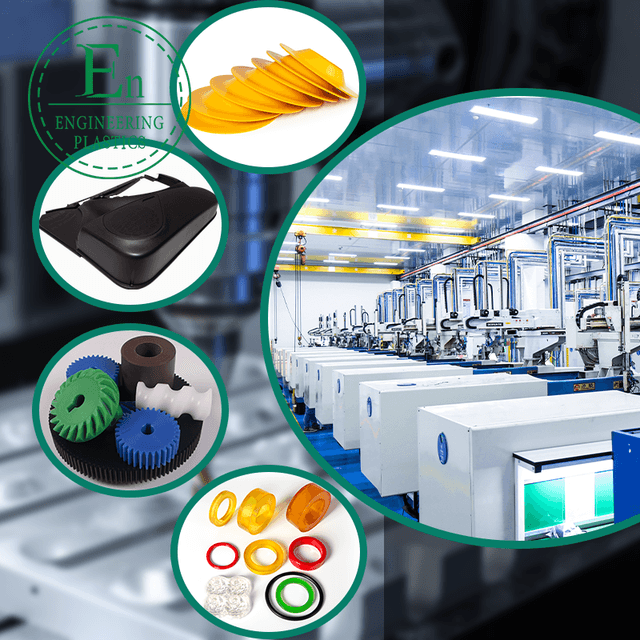

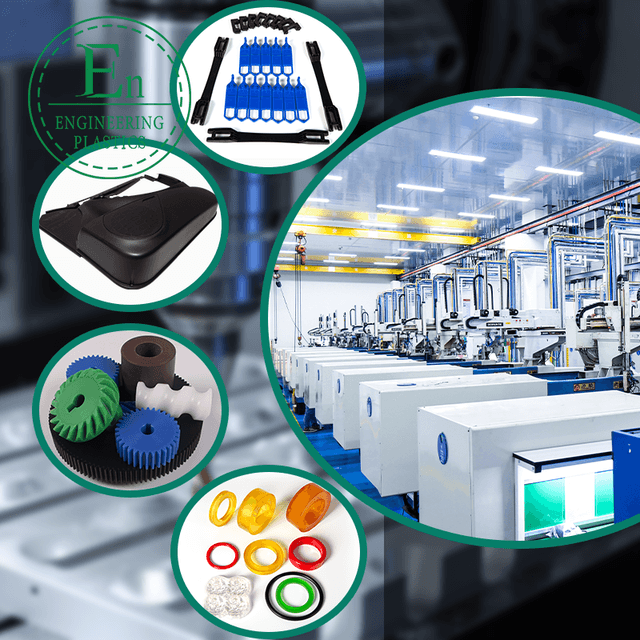

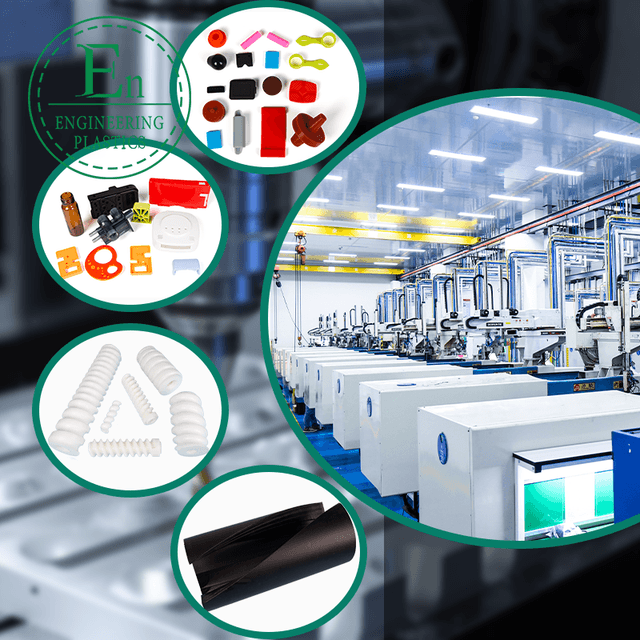

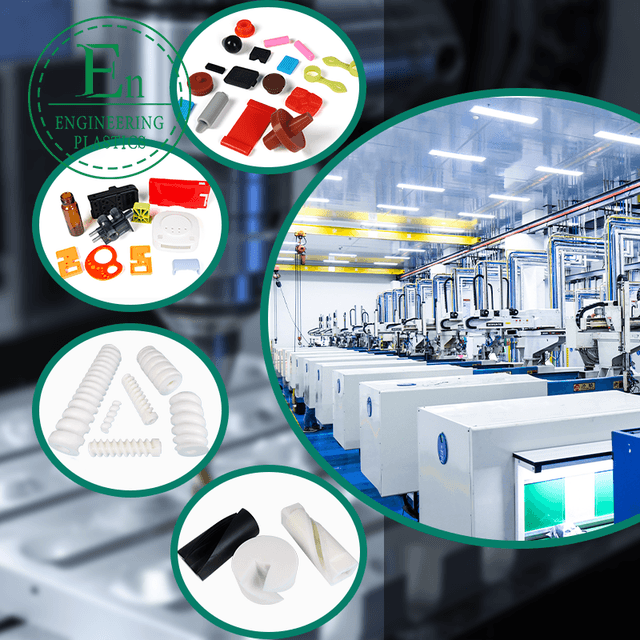

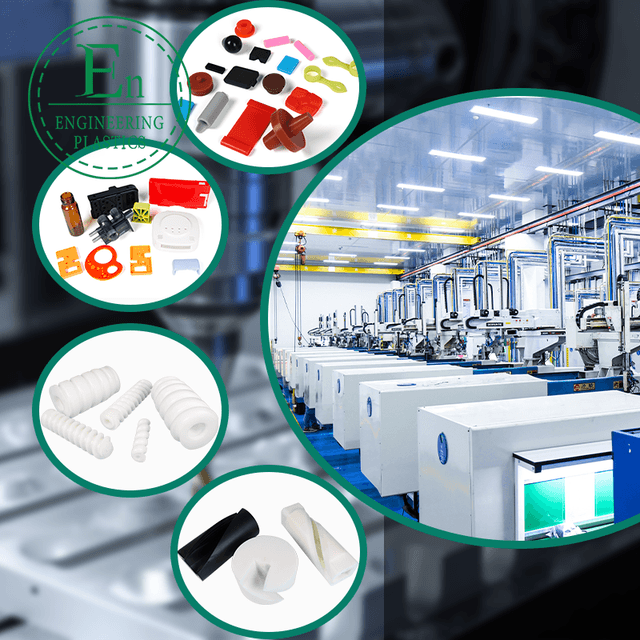

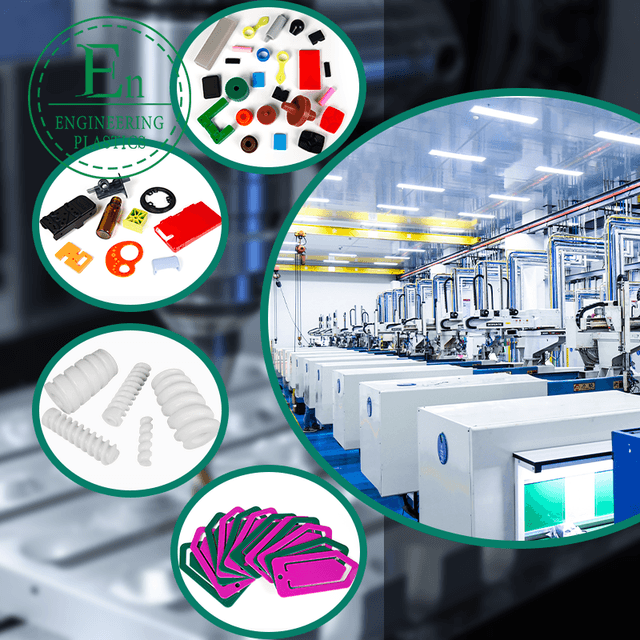

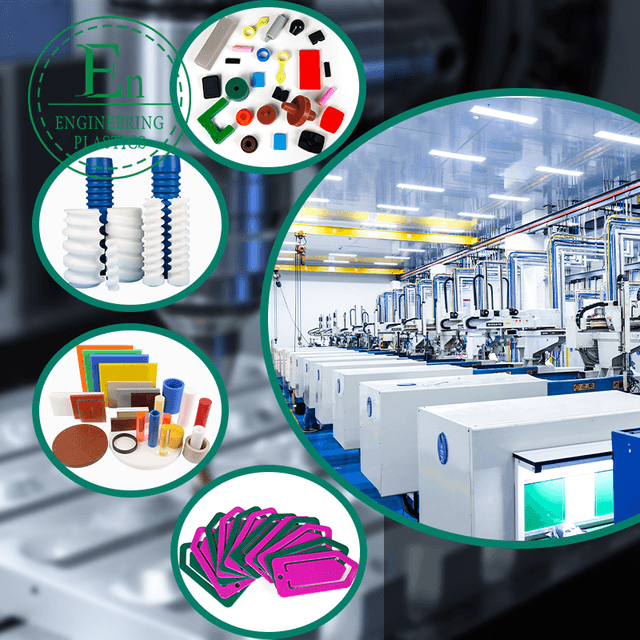

In today's fast-paced world, the demand for high-quality plastic injection molded products spans nearly every industry, from complex automotive systems to essential consumer goods. The success of these items hinges on precision engineering, material durability, and manufacturing efficiency. Achieving a perfect balance of these elements is crucial for any brand looking to deliver reliable and cost-effective solutions. This is where advanced manufacturing processes and superior tooling become indispensable, ensuring that every component meets the highest standards of quality and performance required by competitive global markets.

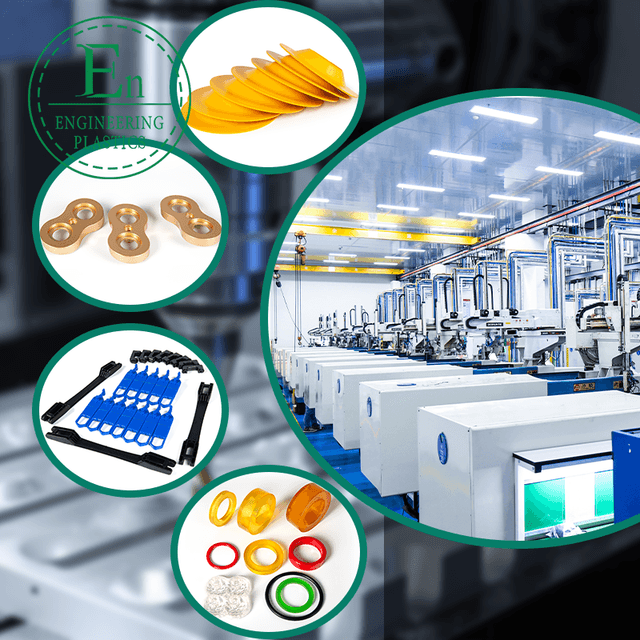

The versatility of injection molding begins with the right material selection, and one of the most trusted processes is HDPE molding. High-Density Polyethylene is a remarkable thermoplastic polymer celebrated for its exceptional strength-to-density ratio, robust chemical resistance, and outstanding impact durability. These properties make it the ideal material for products exposed to harsh conditions, such as industrial containers, chemical drums, outdoor furniture, and automotive fuel tanks. The HDPE molding process allows us to create parts that are both lightweight and incredibly tough, offering a significant advantage in applications where structural integrity and long-term performance are critical.

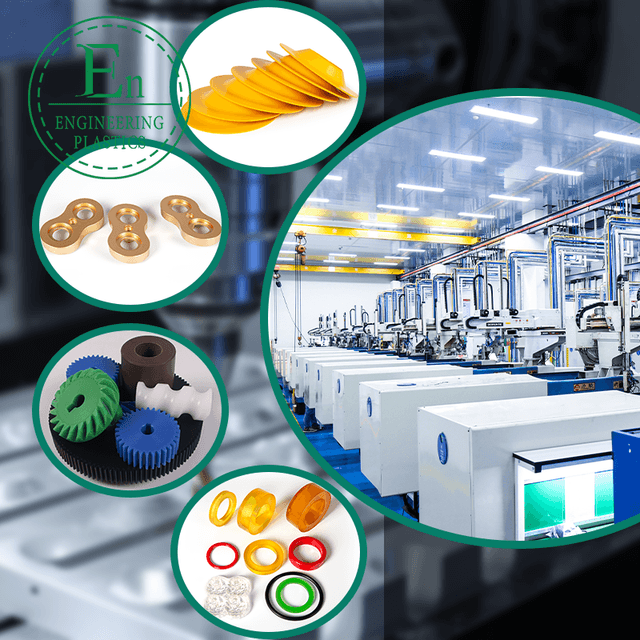

Beyond standard applications, modern manufacturing increasingly requires the production of extremely small and intricate components. This specialized field is expertly handled by mini injection molding. This is not simply about reducing scale; it is a sophisticated technique for achieving microscopic precision and tight tolerances on an industrial level. Mini injection molding is essential for innovating in sectors like medical devices, where it's used for surgical instruments and implants, or in electronics for creating connectors, sensors, and micro-switches. Our mastery of this process overcomes challenges like uniform material flow and rapid cooling in tiny cavities, ensuring flawless and consistent production of even the most delicate parts.

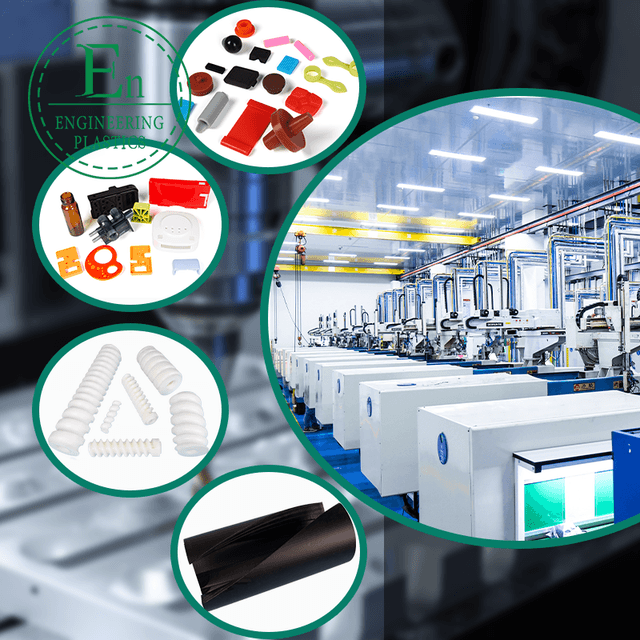

The foundation of any high-quality output is the mold itself, and our industrial molds are engineered to be long-term manufacturing assets. Built for exceptional longevity with a life of 50,000 to 500,000 shots, they are crafted from robust dies and premium-grade materials. This impressive durability significantly reduces the cost-per-part over the product's lifecycle and minimizes interruptions for tool replacement. Each mold is a work of precision, featuring optimal flow structures and intricate detailing to guarantee a flawless finish on all plastic injection molded products, cycle after cycle.

Our commitment to excellence is reflected in the cutting-edge technology embedded in our molds. Every mold undergoes rigorous quality control and is constructed using advanced machining techniques to ensure ultra-precise geometries. Features such as strategically designed cooling systems facilitate swift, uniform cooling, which is vital for reducing cycle times and preventing defects like warping or sink marks. Furthermore, compatibility with ergonomic setups simplifies mold changes and maintenance, maximizing uptime. This holistic design philosophy ensures that whether you are producing large-scale assemblies or leveraging the finesse of mini injection molding, your production line runs with unparalleled efficiency and reliability.

Ultimately, transforming a digital concept into a tangible, high-performance component requires a partnership built on technological expertise and an unwavering commitment to quality. We offer a comprehensive solution for creating superior plastic injection molded products. By mastering versatile techniques and backing them with robust, high-longevity molds, we provide the perfect blend of technological finesse, operational reliability, and cost-efficiency. Let us empower your manufacturing journey and help you bring your innovative designs to life with unmatched precision and quality.