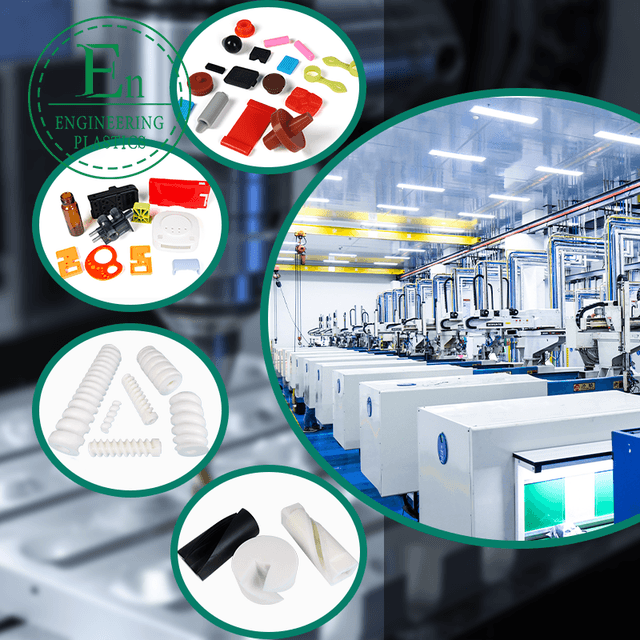

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

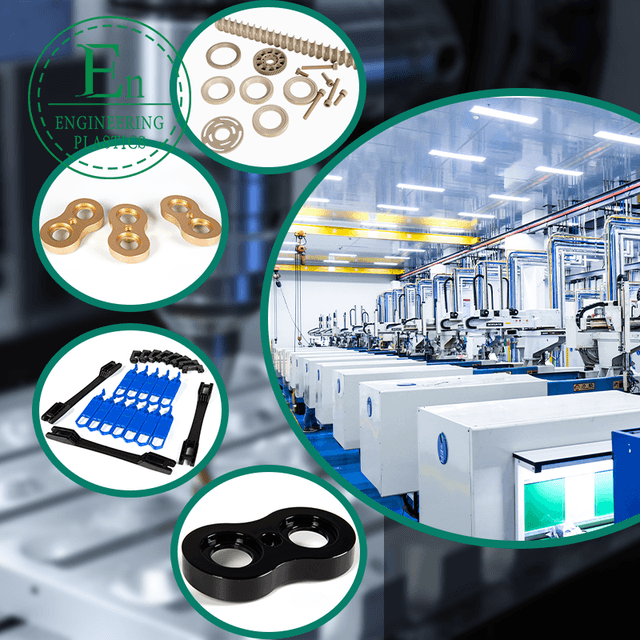

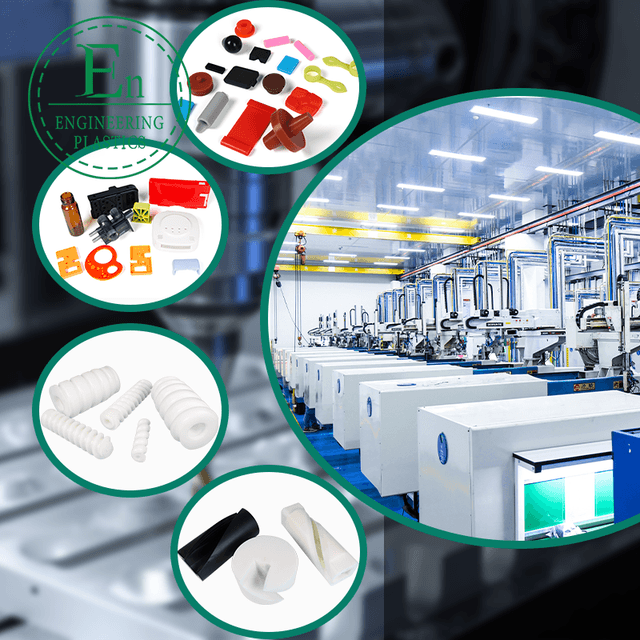

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the fast-paced world of automotive manufacturing, the mould for car parts plays a pivotal role in producing high-quality, precision-engineered components. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting advanced moulds that meet the stringent demands of the industry. Our state-of-the-art facility leverages the expertise of senior engineers with 15-25 years of experience to deliver customized solutions using premium materials like PEEK, PPS, Nylon, ABS, and PTFE. Whether it's for structural elements or intricate assemblies, our mould for car parts ensures seamless production, reducing defects and enhancing efficiency. This commitment to excellence has positioned us as a trusted partner for global clients exporting to the USA, UK, Canada, Germany, and beyond.

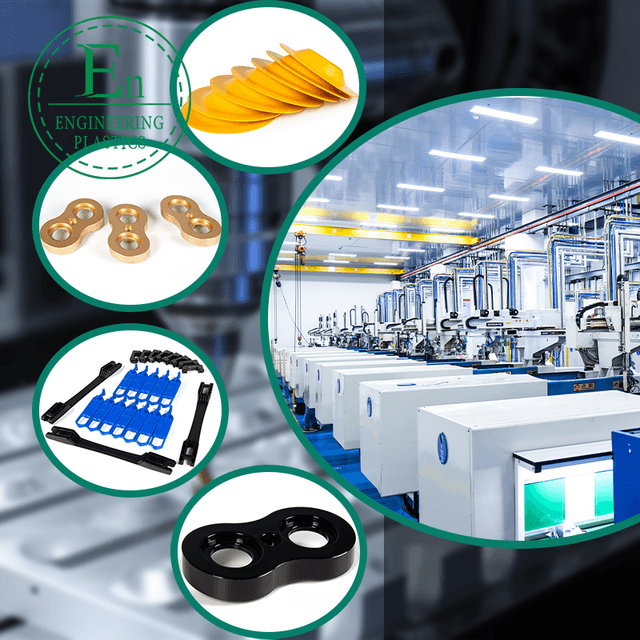

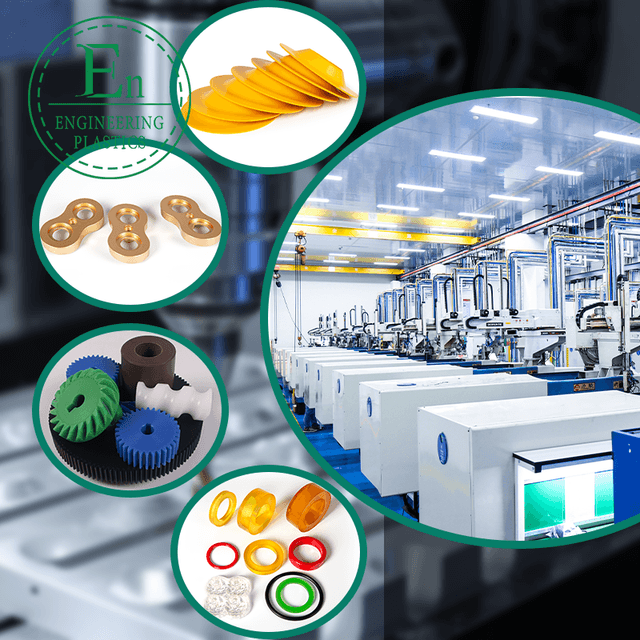

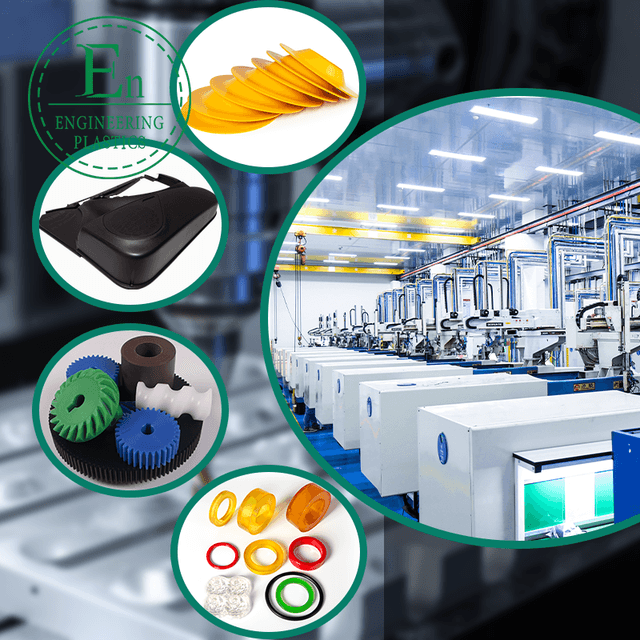

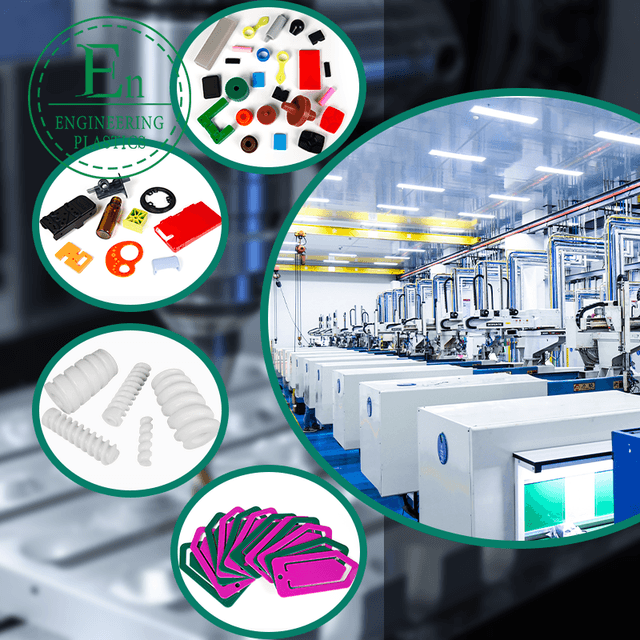

Building on our core capabilities, we integrate innovative designs into our electric mold technology, which is tailored for the rising tide of electric vehicles. The electric mold represents a breakthrough in mould for car parts, optimized for battery housings, motor components, and lightweight frames that demand superior electrical insulation and thermal resistance. Our team provides comprehensive design, research, and development services, allowing for personalized customization that aligns with your specific project needs. These electric molds are engineered to handle high-volume production while maintaining precision tolerances, making them ideal for the automotive sector's shift towards sustainable mobility. With vibrant material options and low-friction properties, our products like precision gears and sealing rings complement these molds, ensuring durable performance in electric drivetrains and power systems.

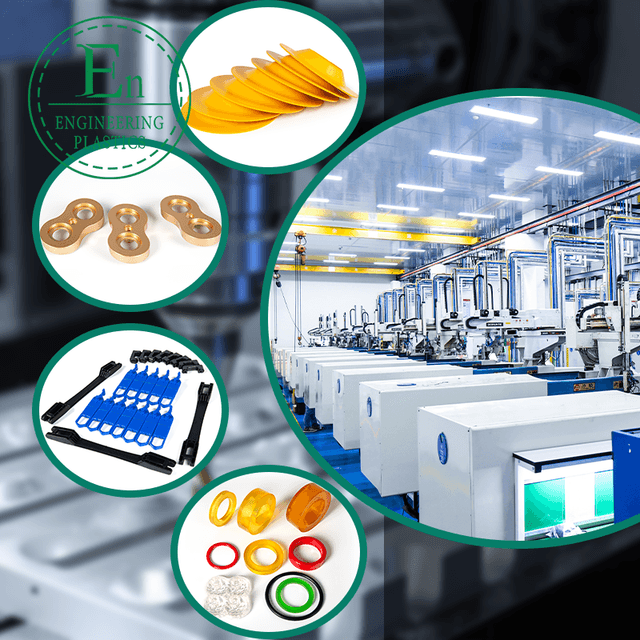

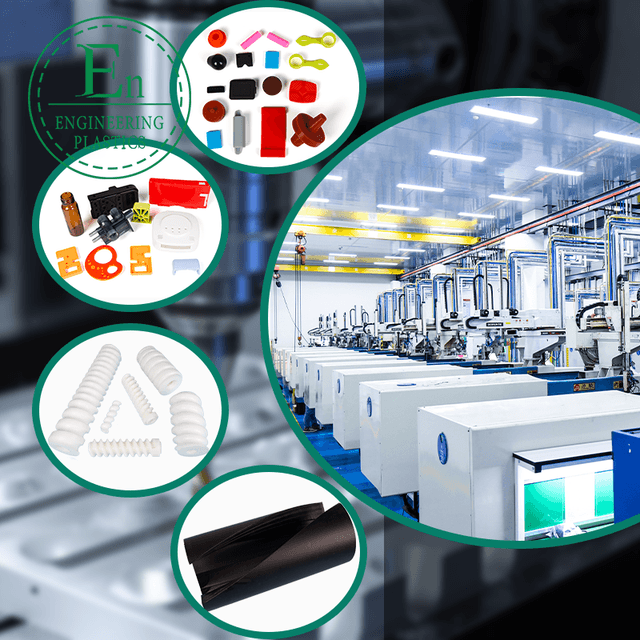

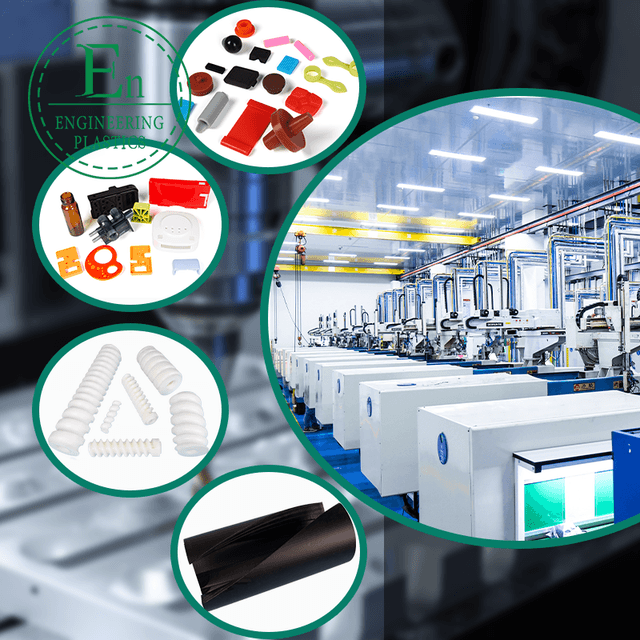

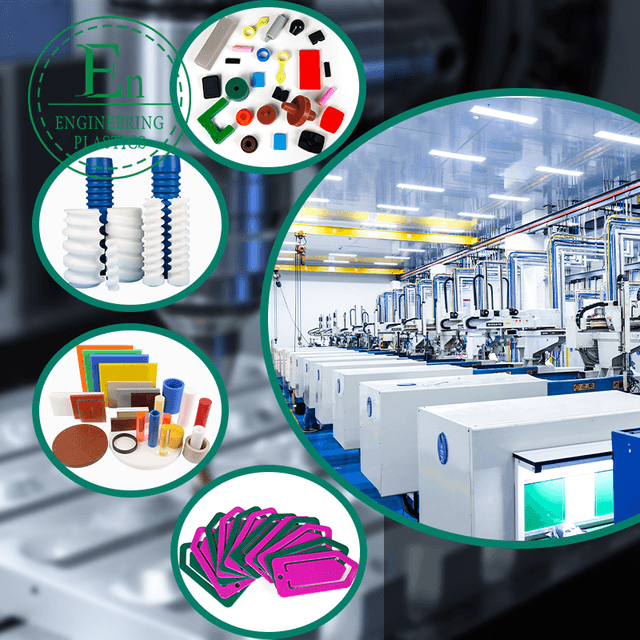

Complementing our offerings, the paing mold—our specialized variant for painting and finishing processes—elevens the aesthetic and functional quality of car parts. This paing mold is meticulously designed to facilitate smooth surface treatments, preventing imperfections during coating applications on exterior panels and trim pieces. As part of our broader mould for car parts lineup, it incorporates advanced engineering plastics that withstand chemical exposures and temperature fluctuations common in automotive painting lines. Our high-tech manufacturing guarantees versatility, from injection molded parts to cable organizers, all produced with an eye on environmental standards and cost-effectiveness. Clients appreciate how our paing molds enhance the visual appeal and corrosion resistance of components, contributing to longer-lasting vehicles that meet international safety regulations.

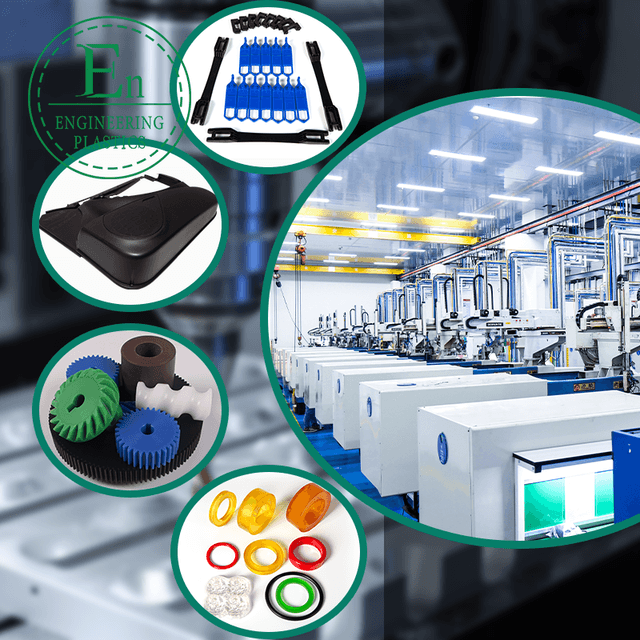

Our dedication to innovation extends across our entire product range, including injection molded parts that exhibit superior strength for automotive applications, precision gears for smooth mechanical operations, and sealing rings that provide leak-proof solutions in hydraulic systems. The cable organizers, with their striking designs, ensure efficient wiring management in complex vehicle architectures. By focusing on mould for car parts alongside electric mold and paing mold technologies, we address the multifaceted challenges of modern manufacturing. Our global reputation stems from reliable exports and tailored services that drive client success. With over decades of combined expertise, Guangdong Engineering Plastics Industries Group Co., Ltd. continues to pioneer solutions that propel the automotive industry forward, fostering partnerships built on quality and precision. As we look to the future, our R&D efforts promise even more advanced moulds that support the evolution of electric and smart vehicles, ensuring our clients stay ahead in a competitive market.