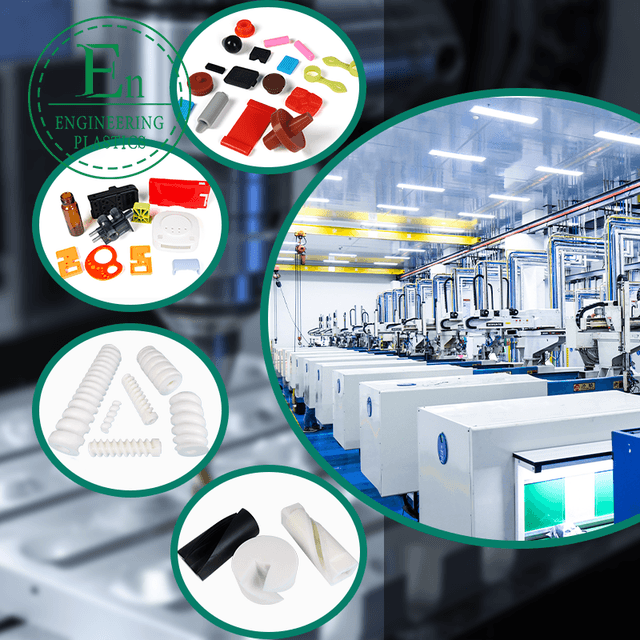

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

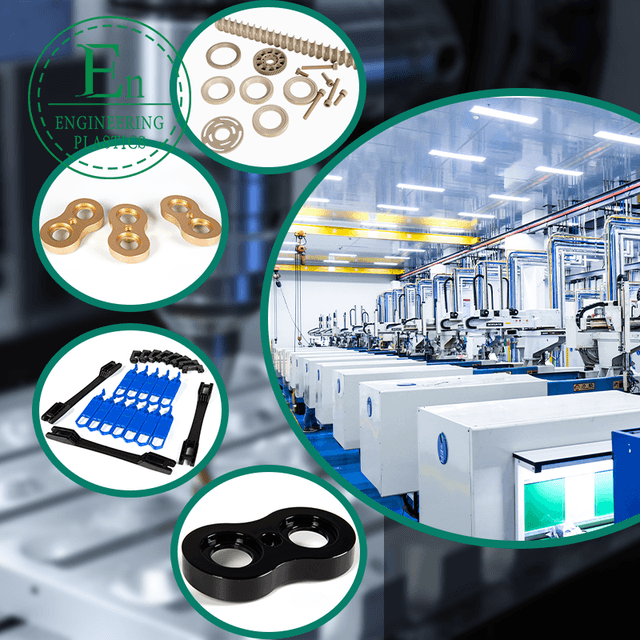

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

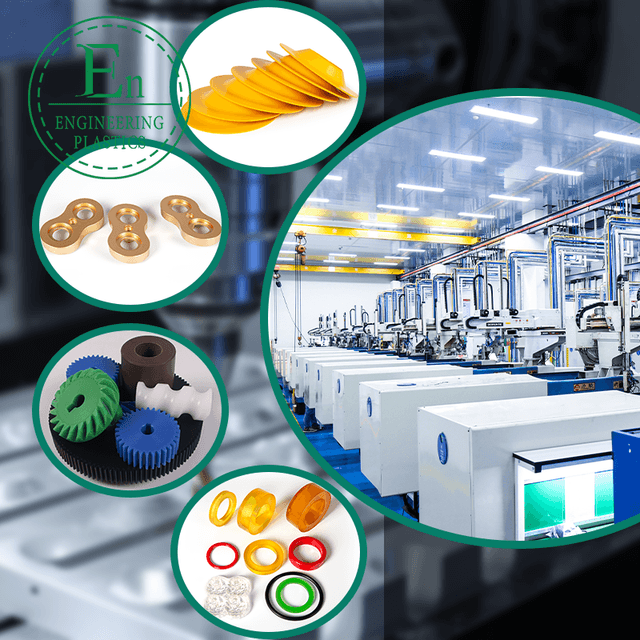

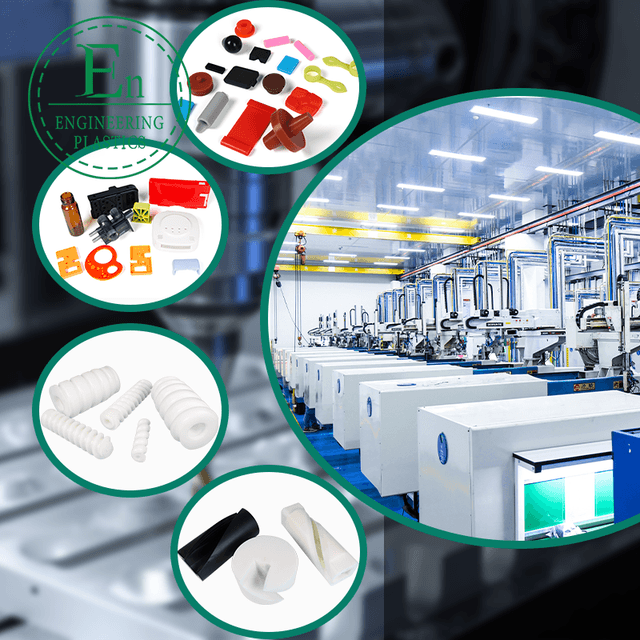

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, the small injection mold stands out as a cornerstone for producing high-quality, intricate components efficiently. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting these essential tools that enable seamless production of engineering plastic parts. With our state-of-the-art facilities and a team of senior engineers boasting 15-25 years of expertise, we deliver small injection molds tailored to your specific needs, ensuring durability, precision, and cost-effectiveness. Whether you're developing prototypes or scaling up production, our small injection molds integrate advanced design principles to minimize defects and maximize output.

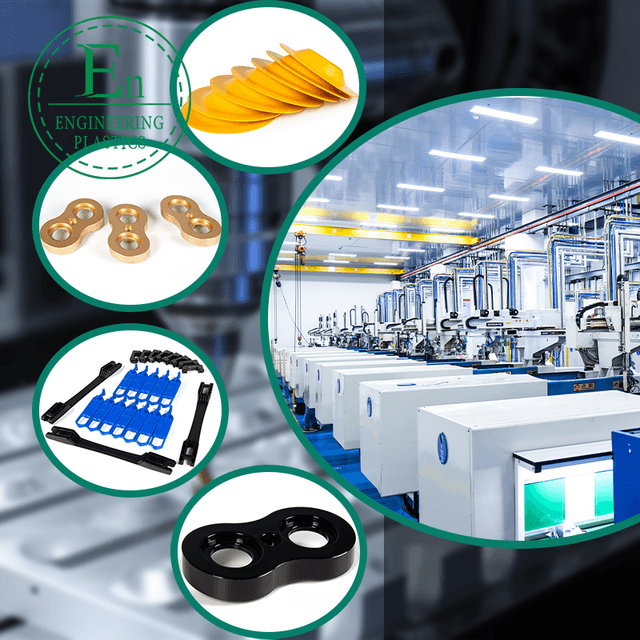

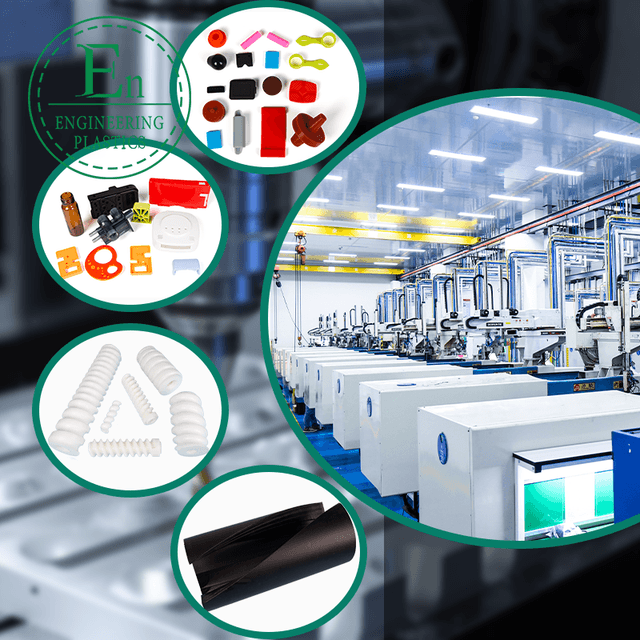

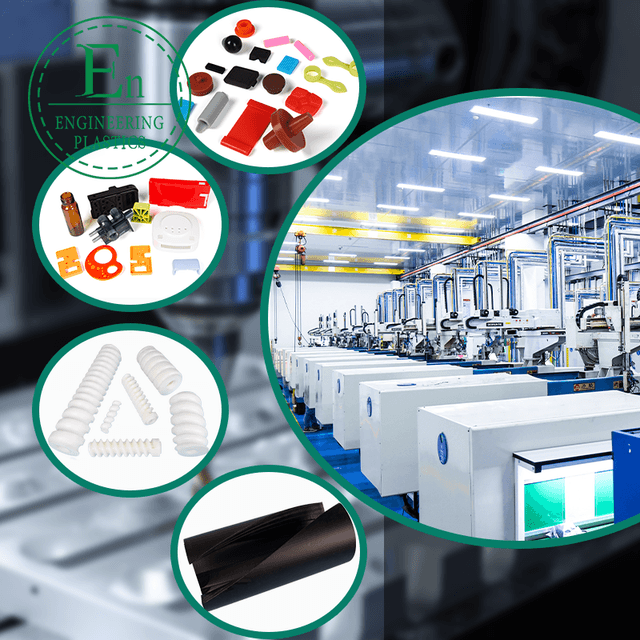

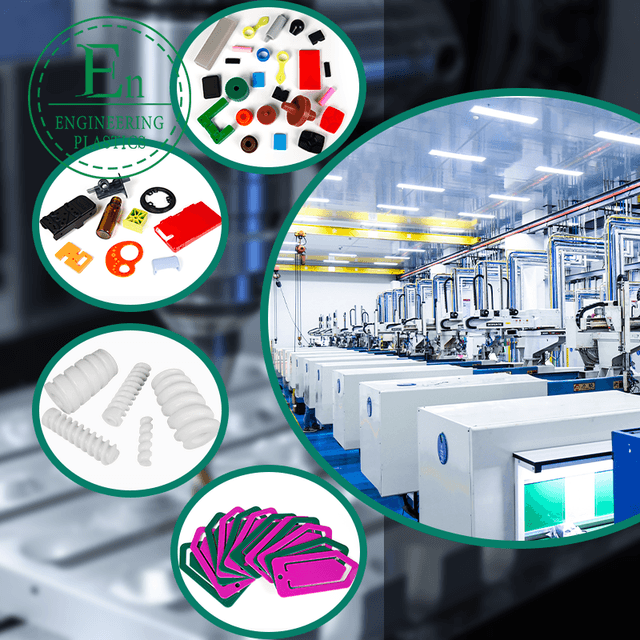

Building on this foundation, our expertise extends to specialized applications like the polyethylene mold, which is ideal for creating robust, lightweight parts used in packaging, automotive, and consumer goods industries. Polyethylene molds produced through our small injection mold technology offer superior resistance to chemicals and impacts, making them a go-to solution for demanding environments. We leverage materials such as high-density polyethylene to fabricate these molds, ensuring they withstand repeated cycles without compromising quality. Our engineers collaborate closely with clients to customize polyethylene mold designs, incorporating features like multi-cavity setups for higher throughput. This approach not only enhances manufacturing efficiency but also aligns with our commitment to sustainable practices by optimizing material use and reducing waste.

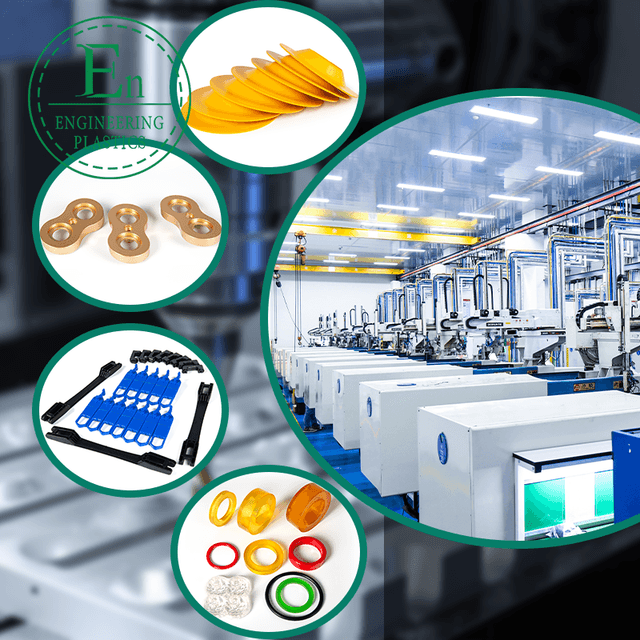

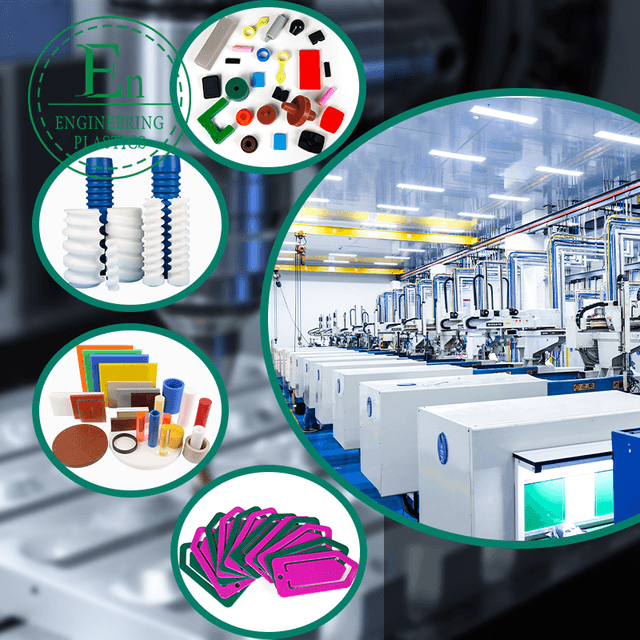

Furthermore, for those exploring flexible alternatives, we excel in making silicone molds that complement our small injection mold offerings. Making silicone molds allows for the creation of detailed, soft-touch components perfect for medical devices, electronics enclosures, and custom prototypes. Our process for making silicone molds involves precise mixing and curing techniques, resulting in molds that capture fine details with exceptional fidelity. These molds are particularly advantageous in low-volume production runs, where the versatility of silicone provides quick turnaround times compared to traditional metal molds. At Guangdong Engineering Plastics Industries Group, we integrate making silicone molds into our broader service portfolio, using advanced simulation software to predict performance and refine designs before production. This ensures that your polyethylene mold or silicone mold projects meet exact specifications, from tensile strength to thermal stability.

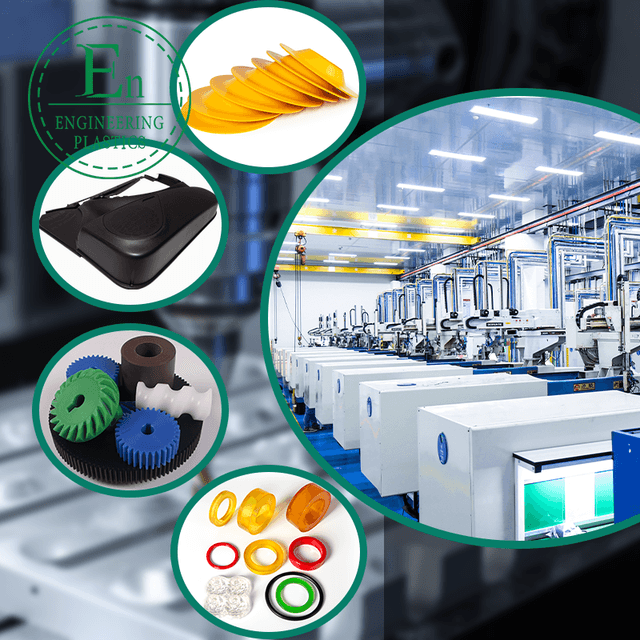

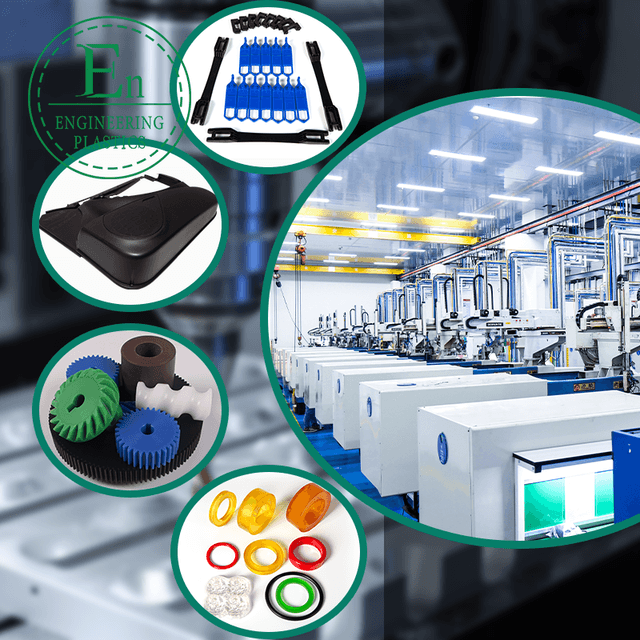

Our global reach underscores the reliability of our small injection mold solutions; we export to key markets including the USA, UK, Canada, and Germany, serving industries that demand uncompromising quality. Clients appreciate our comprehensive capabilities in design, research, and development, allowing for personalized customization of everything from gears and pulleys to sealing rings and bearings made with premium materials like PEEK, PPS, Nylon, ABS, and PTFE. By focusing on innovation, we help you navigate the complexities of modern manufacturing, whether it's optimizing a polyethylene mold for fluid dynamics or perfecting the art of making silicone molds for intricate geometries.

In essence, investing in our small injection mold technology means partnering with a leader in engineering plastics. Our products, including those for polyethylene mold applications and making silicone molds, are engineered to elevate your operations, reduce downtime, and drive competitive advantage. With a proven track record of excellence, Guangdong Engineering Plastics Industries Group Co., Ltd. invites you to explore how our tailored solutions can transform your production processes today.