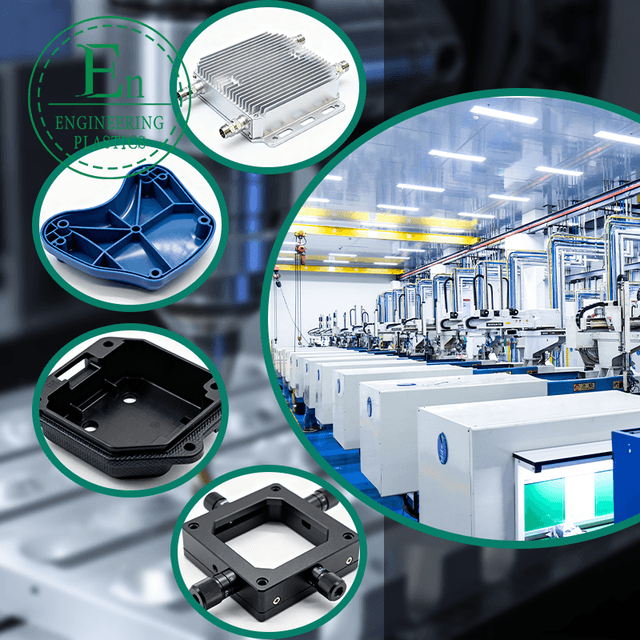

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

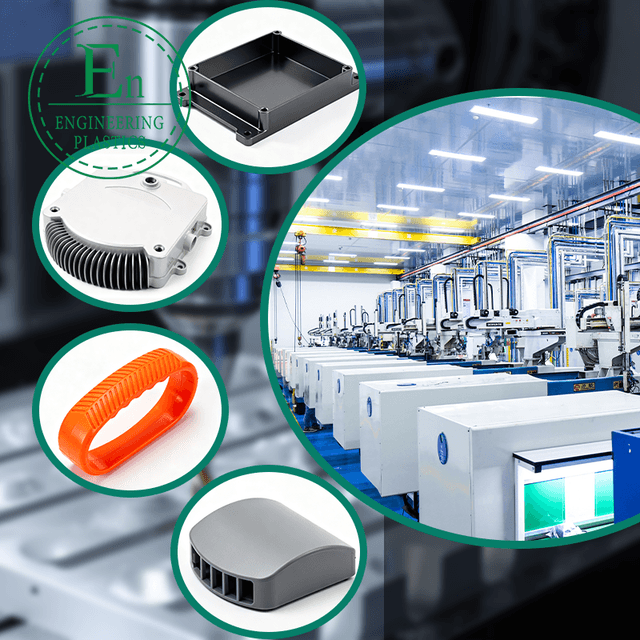

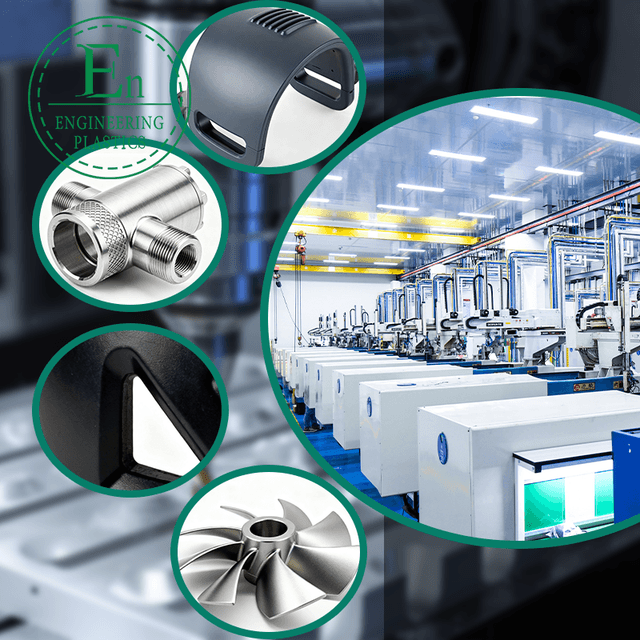

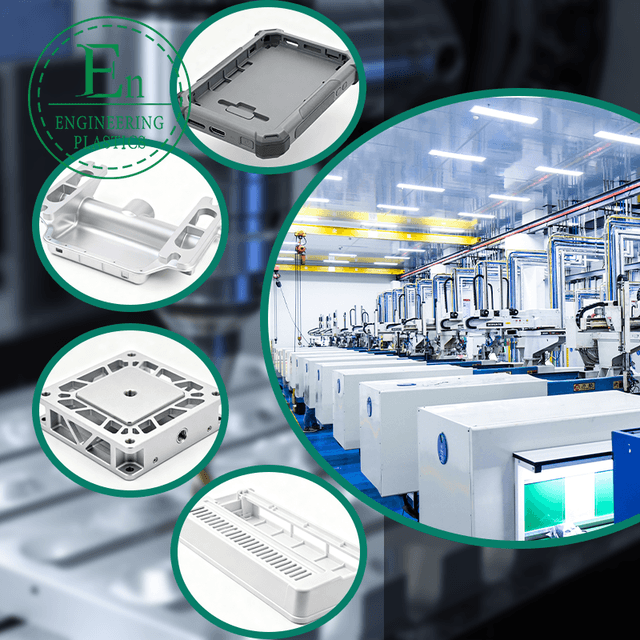

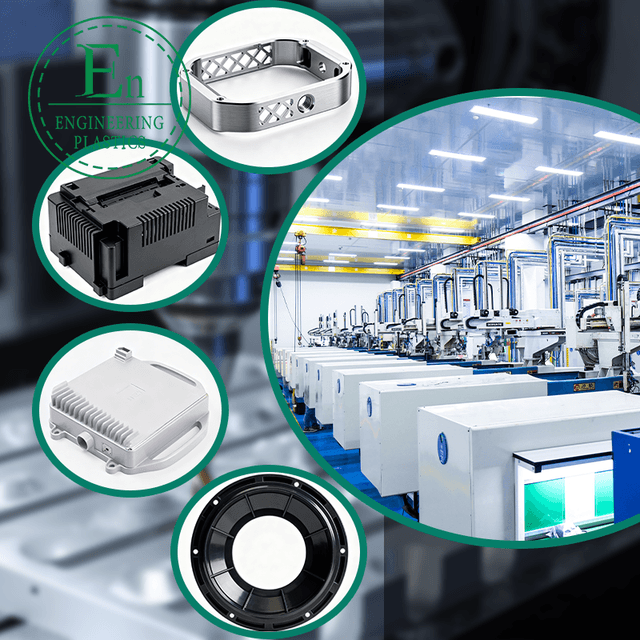

Our expertise includes:

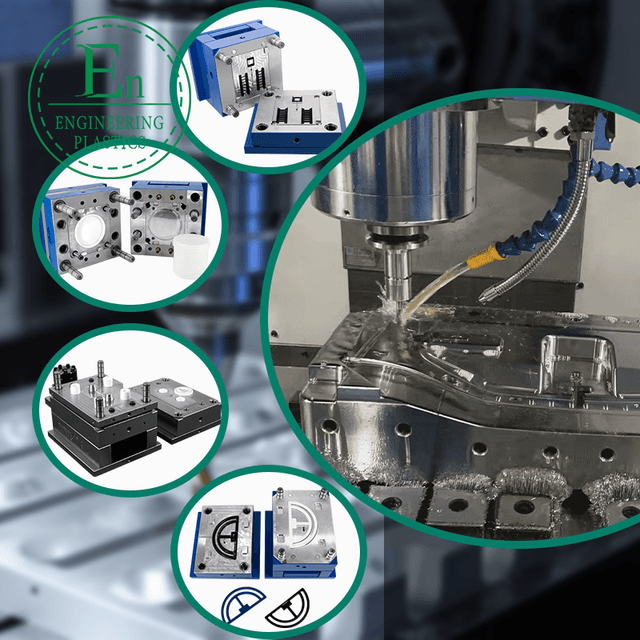

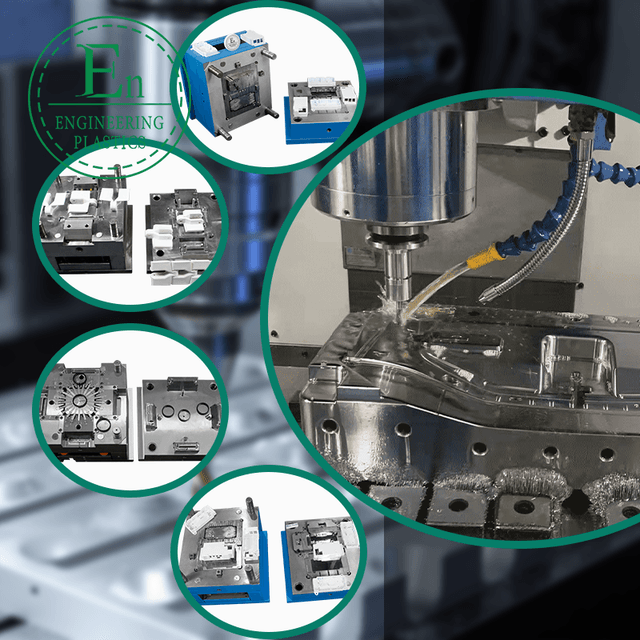

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

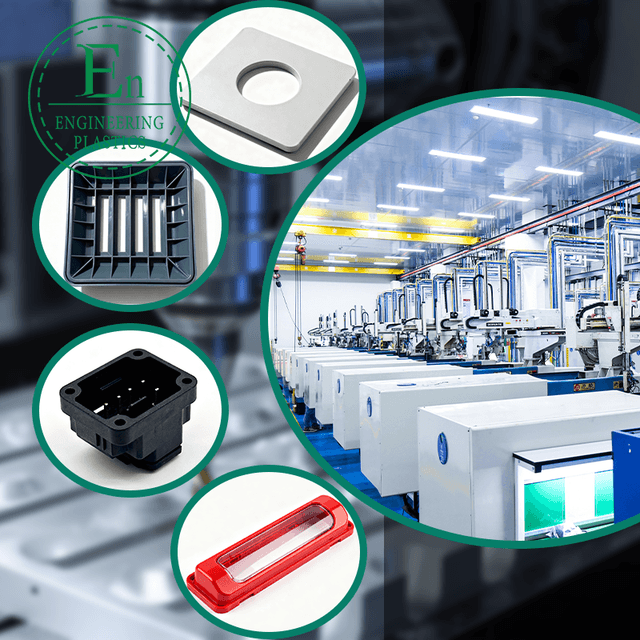

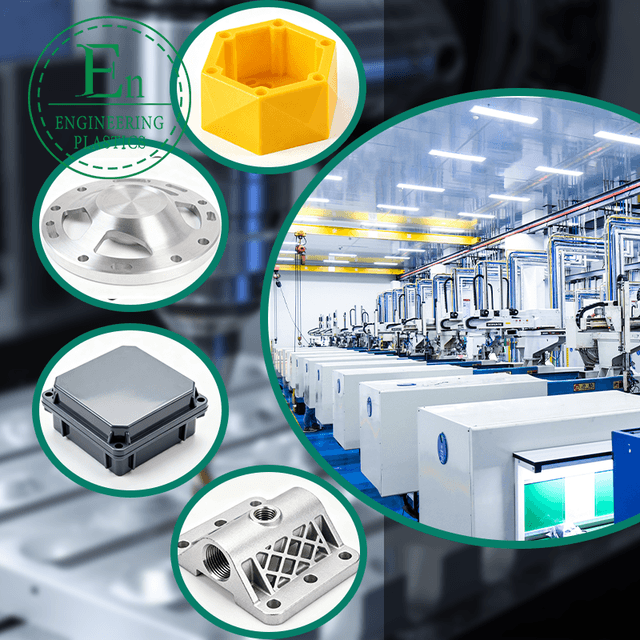

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Achieving flawless results in plastic component manufacturing requires deep expertise and precision engineering, particularly when it comes to preventing common defects. One of the most persistent challenges in the industry is injection mold flashing, a frustrating issue where excess plastic escapes the mold cavity. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage decades of experience to eliminate such imperfections, ensuring every component meets the highest standards of quality. Our commitment begins with understanding the intricate dynamics of the molding process, establishing us as a leading partner for businesses that demand perfection in their custom-engineered parts.

Flashing often occurs due to a variety of factors, including improperly sealed parting lines, insufficient clamping force, or wear on critical machinery components. Our approach as a premier injection mold factory is to address these potential issues proactively through meticulous design, advanced technology, and rigorous quality control. Our team of senior engineers, each with 15 to 25 years of specialized expertise, meticulously designs and maintains molds to prevent any gaps that could lead to material leakage. Furthermore, we precisely calibrate every aspect of the production cycle, from clamping pressure to injection speed, ensuring that the molten plastic remains exactly where it should be. This holistic control is fundamental to producing the clean, sharp, and perfectly formed components our clients expect.

Our comprehensive capabilities extend far beyond just troubleshooting. As a full-service injection mold factory, we offer end-to-end solutions, from initial design and research to final production. We work with a diverse portfolio of high-performance materials, including PEEK, PPS, Nylon, ABS, and PTFE, to create a wide range of products like high-tolerance gears, pulleys, sealing rings, and custom housings. The precision required for these parts leaves no room for error, which is why our mastery over preventing injection mold flashing is so critical. Whether you need a sleek, protective casing or a complex internal component, our facility is equipped to deliver exceptional results that combine aesthetic appeal with robust functionality.

A critical element in maintaining process control and part quality is the injection mold screw. This component is responsible for melting, mixing, and injecting the plastic resin into the mold cavity. An improperly designed or worn injection mold screw can lead to inconsistent melt temperatures and pressures, directly contributing to defects. We utilize state-of-the-art screw technology and conduct regular maintenance to guarantee a consistent, homogenous flow of material. This attention to detail at the component level ensures uniform part density, superior structural integrity, and a flawless surface finish, completely free from the tell-tale signs of injection mold flashing.

Our reputation for excellence is recognized globally, with a strong client base in the USA, UK, Canada, Germany, and beyond. This international trust is built on our unwavering commitment to quality and our ability to solve complex manufacturing challenges. By partnering with Guangdong Engineering Plastics Industries Group Co., Ltd., you are choosing a team dedicated to precision and reliability. We transform your designs into tangible, high-quality plastic components, proving that with the right expertise and technology, flawless manufacturing is not just a goal, but a guarantee.