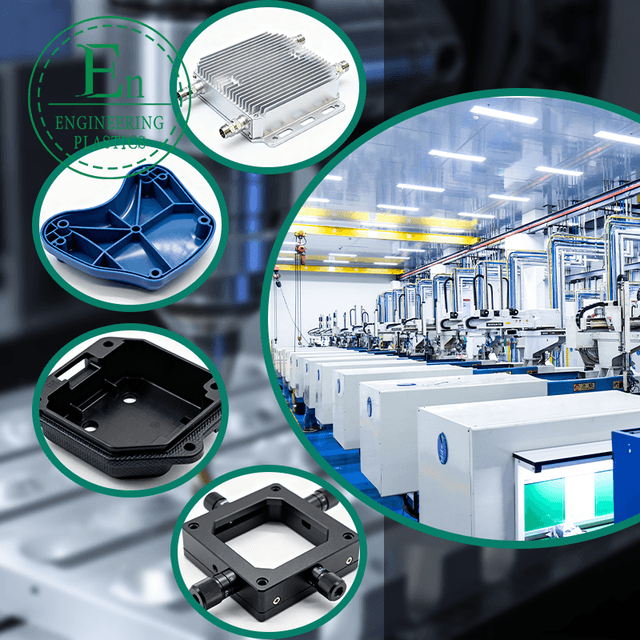

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

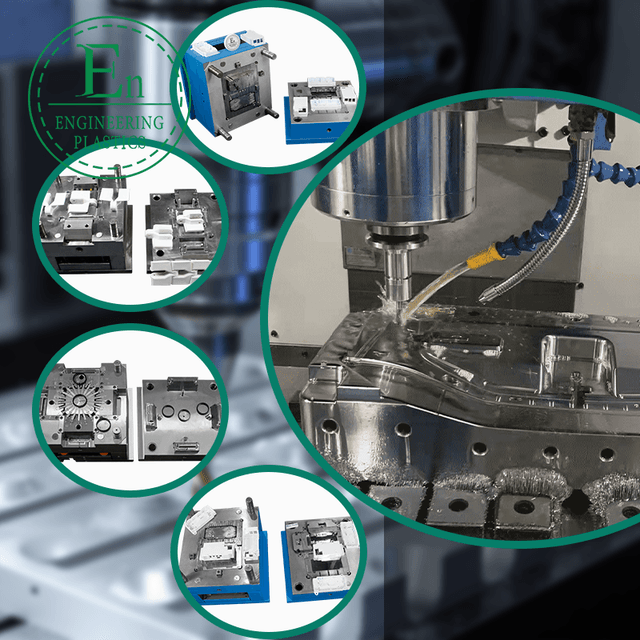

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

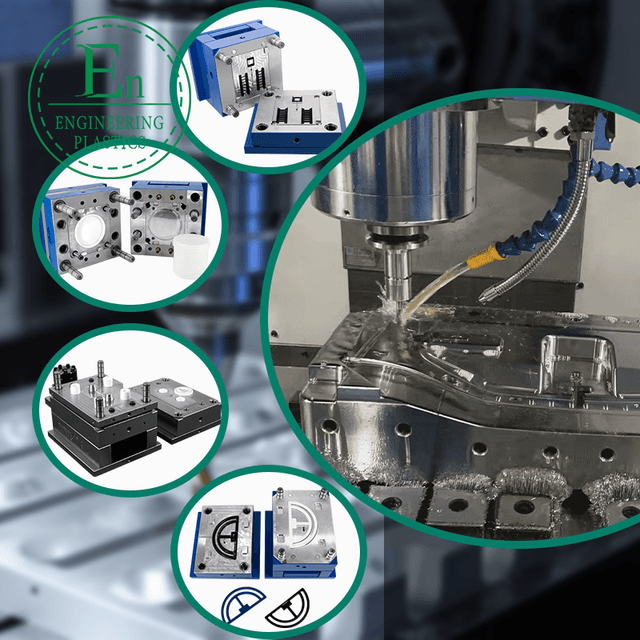

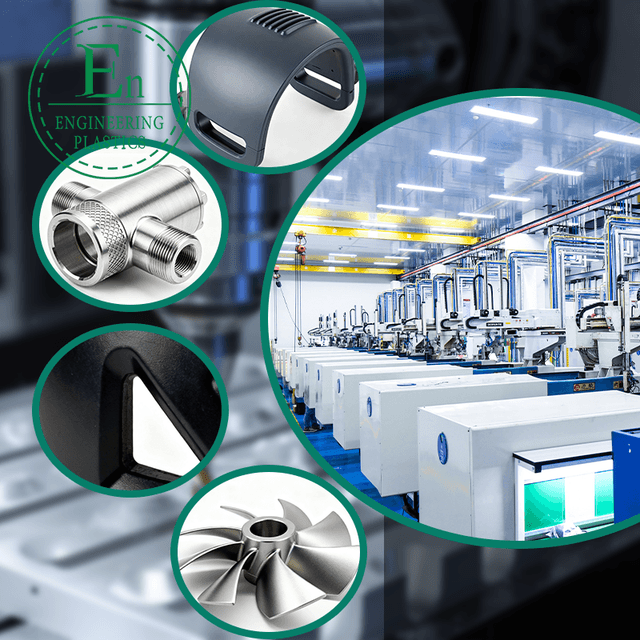

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

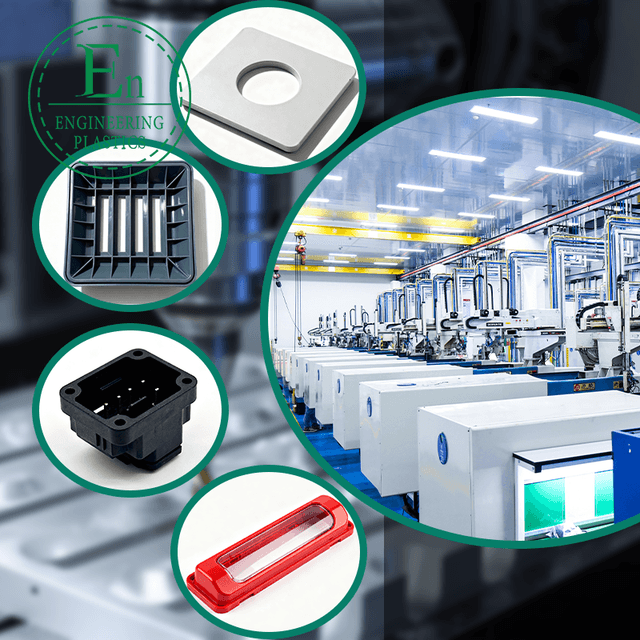

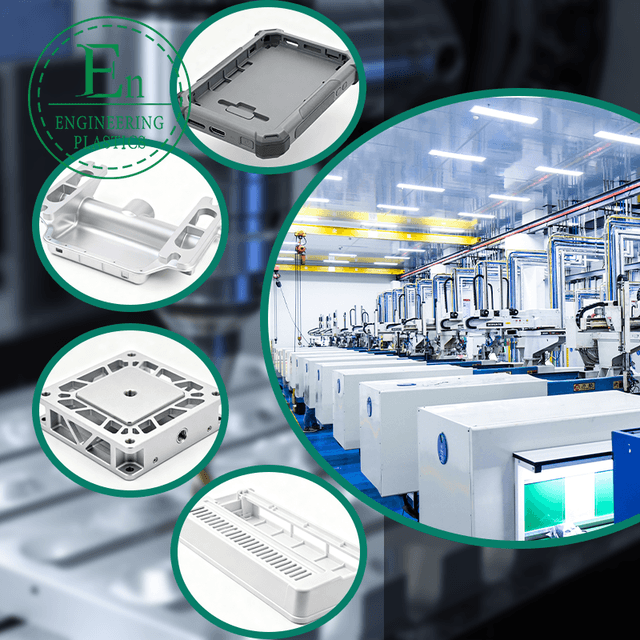

In the world of modern manufacturing, molding plastic injection stands out as a cornerstone technology that drives efficiency and precision. At Guangdong Engineering Plastics Industries Group Co., Ltd., we harness this innovative process to create high-quality engineering plastics tailored for demanding industrial applications. Our expertise in molding plastic injection allows us to produce components that combine durability, versatility, and unmatched design sophistication, serving a global clientele from the USA and UK to Canada and Germany.

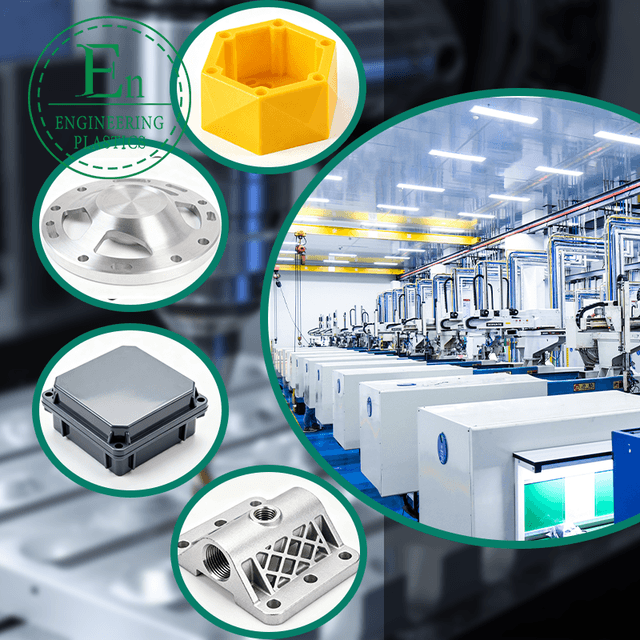

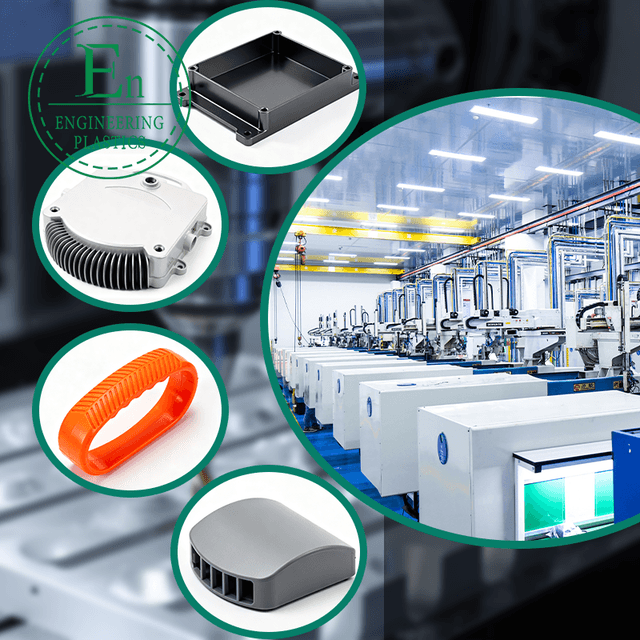

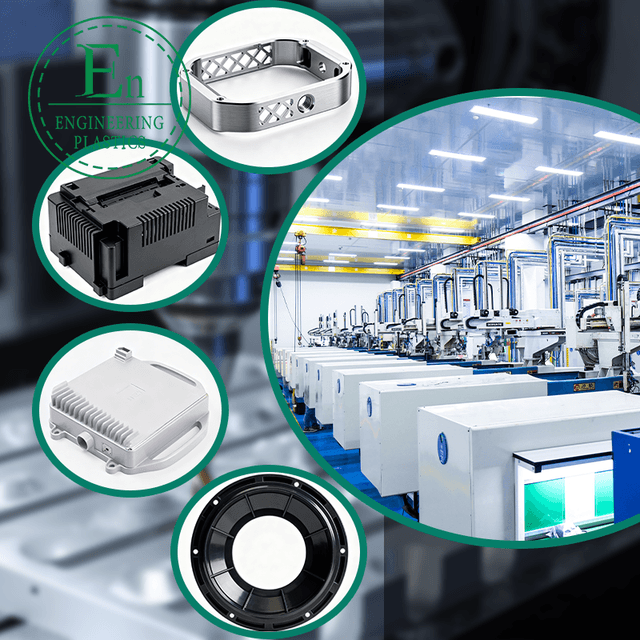

Our molds for injection are engineered with meticulous attention to detail, ensuring optimal performance in every production run. These molds for injection incorporate advanced features like reinforced edges and strategic ribbing, making them ideal for housing electronic devices and mechanical fixtures. Drawing on the 15-25 years of experience from our senior engineers, we offer personalized customization that aligns with your specific needs. Whether it's gears, pulleys, sealing rings, or bearings made from premium materials such as PEEK, PPS, Nylon, ABS, and PTFE, our molds for injection deliver lightweight yet robust solutions without compromising strength. This commitment to excellence has solidified our reputation as a trusted partner in international markets, where reliability and agility are paramount.

Central to our offerings is plastic mould design, a process that integrates cutting-edge research and development to meet diverse industrial challenges. Our plastic mould design philosophy emphasizes seamless integration, with built-in cut-outs and mounting points that facilitate effortless assembly into existing systems. Fabricated in our state-of-the-art facility, every plastic mould design undergoes strict quality assurance to guarantee precision and efficiency. From intricate panel fabrication to larger component assembly, our automated workflows optimize high output while maintaining the accuracy essential for complex applications. This approach not only enhances structural integrity against extreme conditions but also empowers clients with versatile parts that boost equipment performance and longevity.

Molding plastic injection, supported by superior molds for injection and innovative plastic mould design, represents a new era in engineering plastics where function meets unparalleled innovation. Our team's comprehensive capabilities ensure that each product exceeds expectations, fostering industrial growth and design excellence. As we continue to export to key markets worldwide, Guangdong Engineering Plastics Industries Group Co., Ltd. remains dedicated to providing solutions that propel your manufacturing processes forward. With molding plastic injection at the forefront, we invite you to explore how our tailored engineering plastics can transform your operations, delivering the reliability and sophistication your projects demand.

Beyond the basics, our plastic mould design extends to specialized components like those used in demanding environments, showcasing remarkable endurance and adaptability. Clients appreciate the lightweight properties that maintain agility in modern equipment, all while upholding the highest standards of material engineering. This holistic approach in molding plastic injection not only streamlines production but also reduces costs through efficient, high-volume capabilities. Join the ranks of our satisfied international partners and experience the difference that expert craftsmanship makes in your supply chain.