We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of manufacturing, molds for rubber play a pivotal role in producing high-quality components that stand up to rigorous demands. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in creating precision molds for rubber that ensure seamless production processes for industries worldwide. With our advanced engineering capabilities, these molds are designed to handle the unique properties of rubber materials, delivering exceptional accuracy and durability. Our commitment to innovation means that every mold we produce is tailored to meet the specific needs of our clients, whether for automotive parts, seals, or consumer goods. Backed by a team of senior engineers with 15-25 years of expertise, we integrate cutting-edge technology to craft molds that minimize defects and maximize efficiency, setting a new standard in rubber molding solutions.

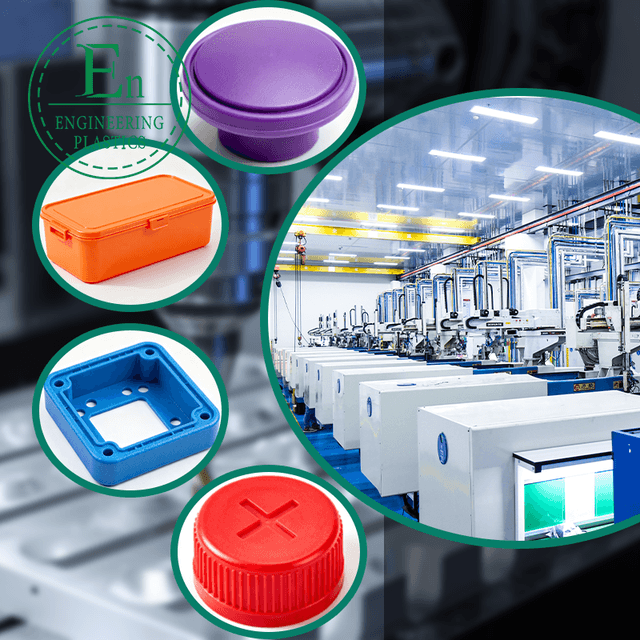

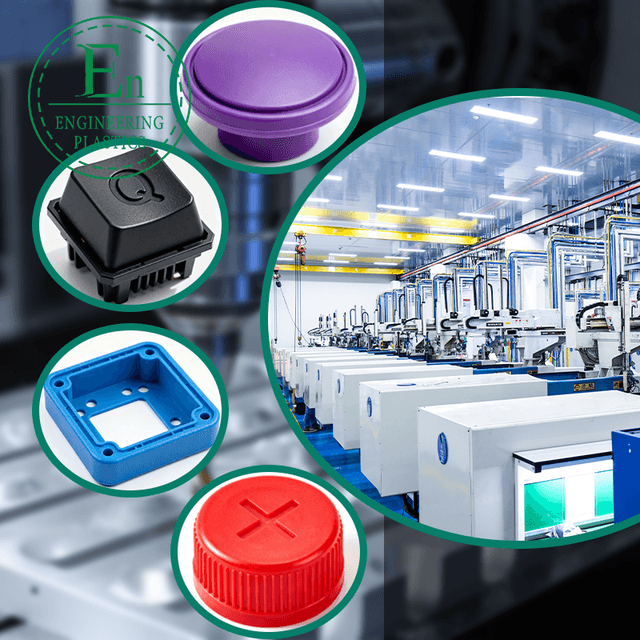

Building on our expertise, our molds for rubber complement a broader range of products, including injection mold accessories that enhance the precision of molding operations. These accessories, such as custom inserts and alignment tools, are essential for maintaining the integrity of the molding process, ensuring that rubber parts emerge with flawless finishes and tight tolerances. We also extend our capabilities to molds for plastic products, which share similar precision requirements but cater to the versatility of thermoplastics like Nylon, ABS, and PEEK. In our state-of-the-art facility, we manufacture these molds alongside durable components like vibrant purple and red caps, robust black keycaps, and sturdy blue enclosures. Each item is forged from high-grade engineering plastics, making them ideal for electronics, machinery, and industrial applications. Our streamlined manufacturing process emphasizes efficiency and innovation, allowing us to offer both standard and custom designs that exceed industry standards.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our personalized approach to customization and comprehensive design, research, and development services. Serving clients from the USA, UK, Canada, Germany, and beyond, we have built a strong global reputation for reliability and quality. For instance, our molds for rubber are engineered to withstand high pressures and temperatures, ensuring long-lasting performance in demanding environments. Similarly, our injection mold accessories are crafted to integrate seamlessly with existing setups, reducing downtime and boosting productivity. When it comes to molds for plastic products, we leverage materials like PPS, PTFE, and more to create solutions that are not only functional but also resistant to wear and corrosion. Whether you're producing gears, pulleys, sealing rings, or bearings, our products deliver superior performance. We take pride in our ability to adapt to unique project requirements, providing end-to-end support from initial concept to final production. This holistic approach ensures that our clients receive molds and accessories that align perfectly with their operational goals, fostering innovation and growth in their businesses.

As we continue to expand our offerings, Guangdong Engineering Plastics Industries Group Co., Ltd. remains dedicated to excellence in every facet of production. Our molds for rubber, injection mold accessories, and molds for plastic products are more than just tools—they are the backbone of efficient, high-quality manufacturing. By choosing our solutions, clients benefit from our decades of experience, global reach, and unwavering focus on quality. Explore our range today and discover how we can elevate your production capabilities with precision-engineered molds and components designed for the future.