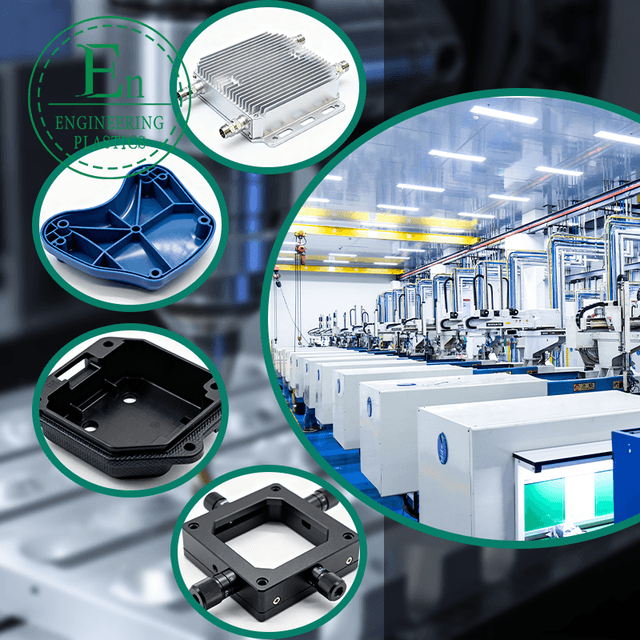

Injection molding companies are at the forefront of innovation, revolutionizing how we implement manufacturing techniques for various industries. One notable advancement in this domain is the introduction of OEM/ODM Customized Solutions in Engineering Plastics. These solutions are specifically tailored to address the diverse needs of sectors like industrial design, consumer electronics, automotive engineering, and smart home solutions.

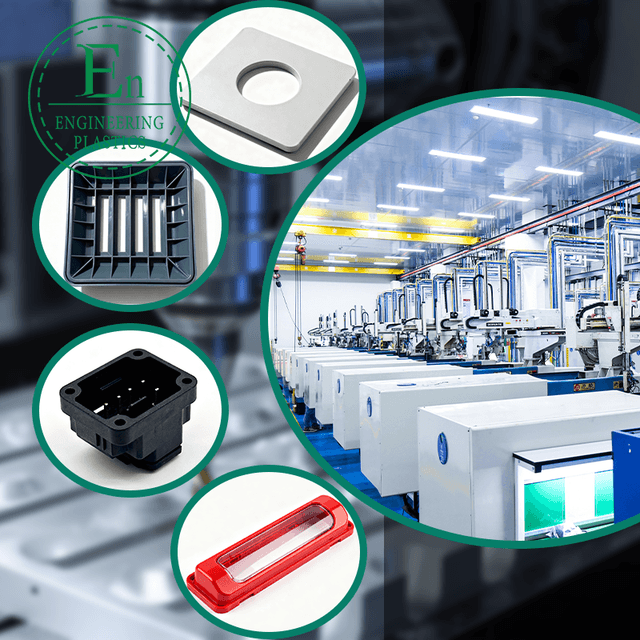

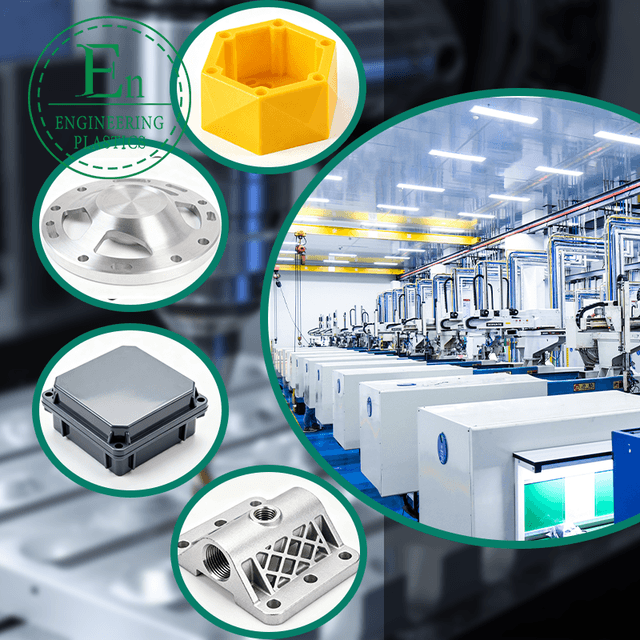

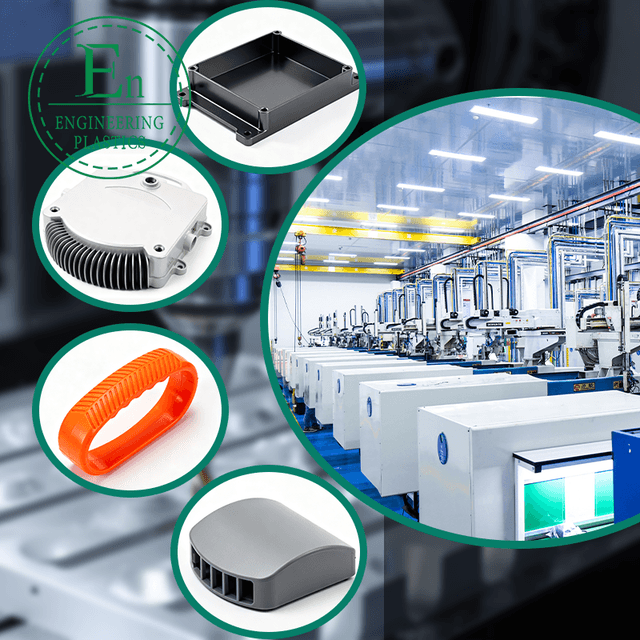

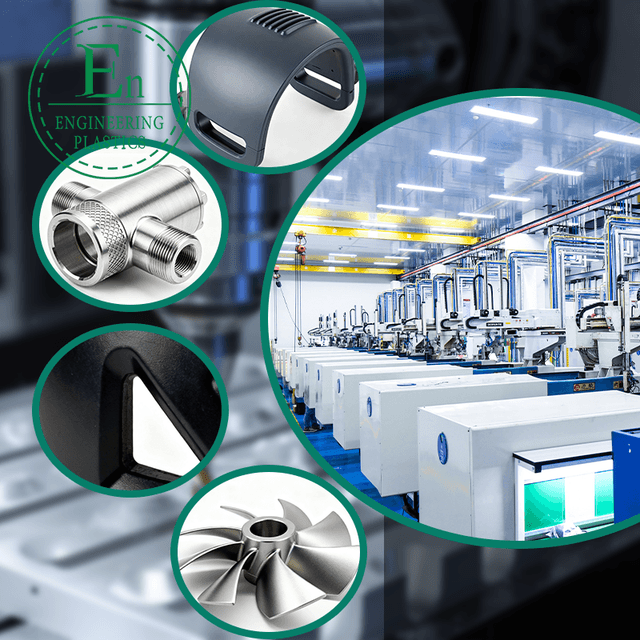

At the core of injection molding companies’ expertise lies the precision and versatility of these customizable solutions. Whether crafting sleek electronic casings, durable gear mechanisms, robust housing structures, or intricate assembly components, the quality is unmatched. These products utilize high-performance engineering plastics known for their durability, heat resistance, wear resistance, and lightweight design. Designs ranging from complex geometries to sleek ergonomic finishes underline the flexibility and efficiency injection molding companies bring to the table.

For the automotive industry, these solutions offer mechanical precision in bold designs, ensuring vehicles not only look exceptional but perform optimally under pressure. In consumer electronics, injection molding companies provide vibrant and functional plastic products that enhance the overall look and feel while maintaining performance standards. Smart home solutions benefit equally, with components meticulously designed to marry aesthetics and utility seamlessly.

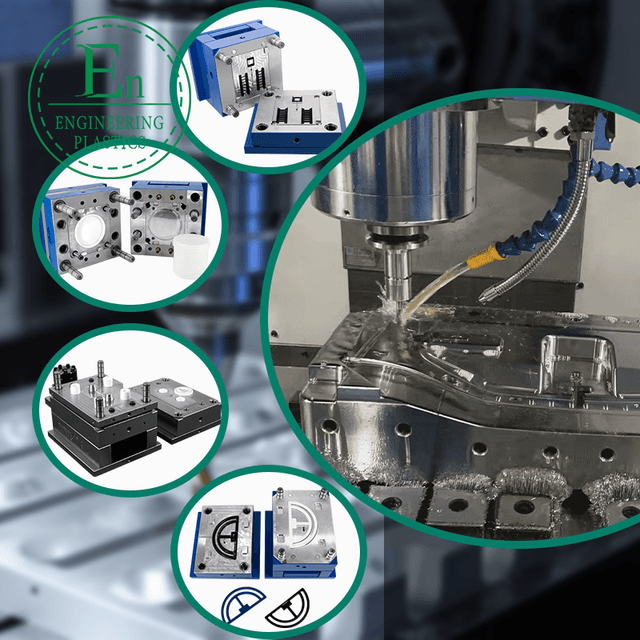

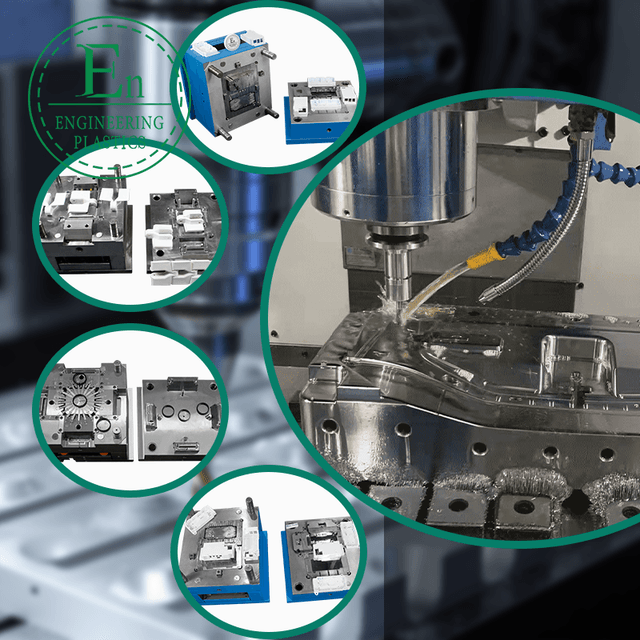

This isn’t just manufacturing; it’s a collaborative process that bridges innovation and imagination. OEM/ODM customization allows engineers, designers, and forward-thinking professionals to personalize products to the finest detail. Whether optimizing industrial assemblies, streamlining device functions, or achieving ergonomic perfection, every piece created reflects progress, strength, and refined aesthetics. Injection molding companies have truly transformed the manufacturing landscape, fulfilling visions with impeccable adaptability and precision.