We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

The world of modern manufacturing relies heavily on the precision and reliability of its smallest components. The process of injection moulding has revolutionized how we produce complex, high-performance parts, forming the backbone of industries from automotive to electronics. At Guangdong Engineering Plastics Industries Group Co., Ltd., we harness decades of expertise to deliver engineering plastic components that meet the most stringent standards. Our commitment to innovation and quality ensures that every gear, pulley, and connector we produce not only fulfills its function but enhances the overall performance and longevity of the final product, setting a benchmark for excellence in the industry.

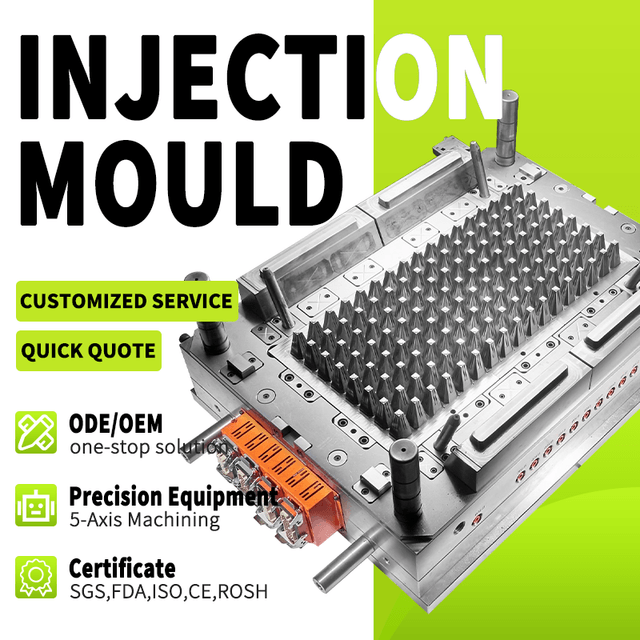

A critical element in achieving superior results in plastics manufacturing is the technology used within the mold itself. The injection mold hot runner system represents a significant advancement over traditional cold runner systems. Unlike cold runners, which solidify with the part and must be removed and discarded or recycled, a hot runner system keeps the plastic in a molten state right up to the gate of the part cavity. This sophisticated method offers numerous advantages, including the elimination of material waste from runners, faster production cycle times, and improved consistency and quality in the final parts. This technology is essential for producing the intricate and flawless components that modern applications demand, ensuring optimal material flow and perfect replication of the mold design every time.

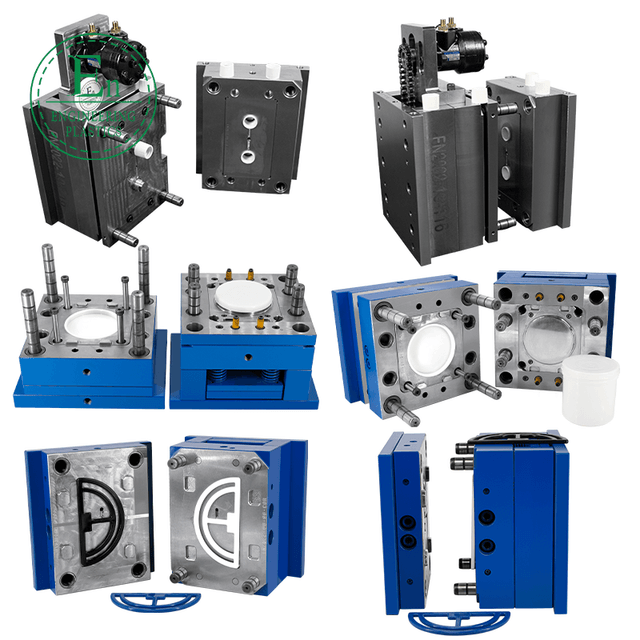

The versatility of our manufacturing process allows us to utilize various injection mold types to create a vast portfolio of products. Each mold is meticulously designed to produce specific components, from high-strength PEEK gears for demanding industrial machinery to flexible PTFE sealing rings for critical applications. Our product range showcases an assortment of intricately designed plastic elements, each serving specific roles. You will notice vibrant colors which often denote specific material properties, from the robust reliability of a black cylindrical sheath to the high-visibility red of an angular lever. Leveraging our deep understanding of different injection mold types and materials like PPS, Nylon, and ABS, we can tailor components to exact client specifications, ensuring they deliver on strength, flexibility, and resistance to wear and tear.

The success of our advanced injection moulding processes is driven by the unparalleled expertise of our team. Our senior engineers, with 15 to 25 years of experience in the field, lead our comprehensive design, research, and development efforts. This deep well of knowledge allows us to offer truly personalized customization, transforming a client's concept into a tangible, high-performance product. We do not just manufacture parts; we engineer solutions. This commitment to excellence has allowed Guangdong Engineering Plastics Industries Group Co., Ltd. to build a strong global reputation, proudly serving clients in the USA, UK, Canada, Germany, and beyond. Our ability to consistently deliver top-tier engineering plastic products has made us a trusted partner for businesses worldwide.

In conclusion, the synergy between advanced manufacturing techniques, such as the use of an injection mold hot runner, and a profound understanding of material science is what defines the quality of modern plastic components. By mastering the nuances of different injection mold types and the broader injection moulding process, we provide solutions that enhance operational efficiency, ensure longevity, and drive innovation across diverse sectors. At Guangdong Engineering Plastics Industries Group Co., Ltd., our experienced team is dedicated to pushing the boundaries of what is possible with engineering plastics. We are committed to providing our domestic and international partners with components that are not just manufactured, but meticulously engineered for a resilient and sustainable future.