We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

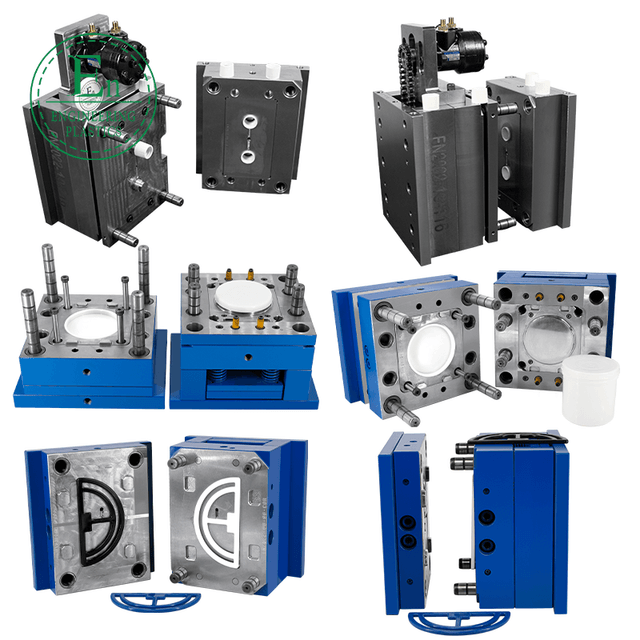

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

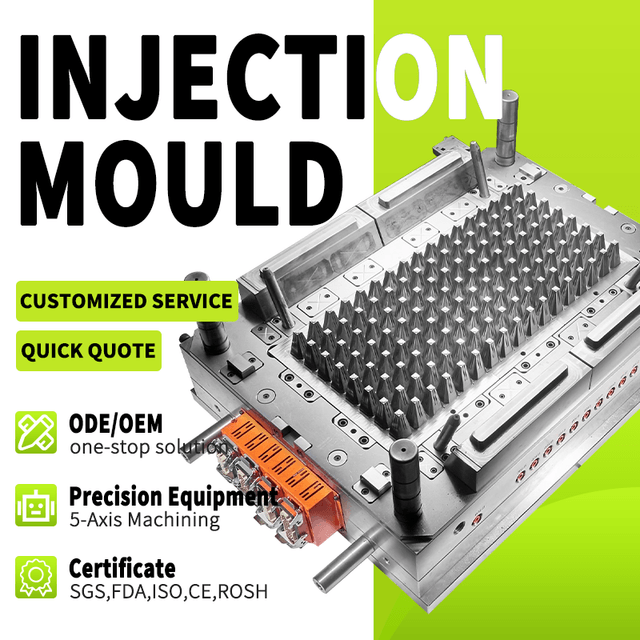

As a leading renewable energy plastics manufacturer, Guangdong Engineering Plastics Industries Group Co., Ltd. is at the forefront of innovation in the plastics industry, providing cutting-edge solutions that cater to sustainable and efficient manufacturing needs. Our expertise extends to creating high-quality products like the state-of-the-art Injection Mould, which embodies precision and adaptability for various applications. This renewable energy plastics manufacturer focuses on integrating advanced technologies to support eco-friendly practices, ensuring that our offerings align with global demands for greener production methods. By leveraging our deep knowledge in materials such as PEEK, PPS, Nylon, ABS, and PTFE, we deliver products that enhance performance while minimizing environmental impact.

In the realm of industrial machinery plastics supplier, our Injection Mould stands out as a versatile tool designed for maximum efficiency and precision. Engineered with 5-Axis Machining technology, this mould ensures unparalleled accuracy, making it ideal for industrial machinery plastics supplier needs where reliability is paramount. We understand the challenges faced by manufacturers in sectors like renewable energy, and our moulds are customized to meet OEM/ODM requirements, offering a one-stop solution for production lines. As an industrial machinery plastics supplier, we prioritize safety and compliance, with certifications like SGS, FDA, ISO, CE, and ROHS guaranteeing that our products adhere to the highest international standards. This not only optimizes operational efficiency but also supports the creation of durable components for machinery used in renewable energy applications, such as wind turbine parts or solar panel assemblies.

Furthermore, as a packaging plastic parts manufacturer, we extend our capabilities to produce specialized moulds that facilitate the creation of sustainable packaging solutions, reducing waste and promoting recyclability. Our team of senior engineers, with 15-25 years of expertise, brings personalized customization to every project, from initial design to final production. This packaging plastic parts manufacturer approach allows us to serve a global clientele, including exports to the USA, UK, Canada, Germany, and beyond, building a reputation for excellence in engineering plastics. Whether you're scaling up production for renewable energy components or refining packaging designs, our Injection Mould integrates seamlessly, driving innovation and productivity while maintaining strict environmental credentials.

Beyond our core offerings, Guangdong Engineering Plastics Industries Group Co., Ltd. continues to push boundaries as a renewable energy plastics manufacturer by investing in research and development for new materials and technologies. This commitment ensures that our products, like the Injection Mould, not only meet current industry standards but also anticipate future trends in sustainability. With quick quote options and tailored services, we make it easier for clients to bring their ideas to life, fostering long-term partnerships that benefit both domestic and international markets. In an era where efficiency and eco-friendliness are key, choosing us as your industrial machinery plastics supplier or packaging plastic parts manufacturer means opting for a partner dedicated to quality, innovation, and global excellence.