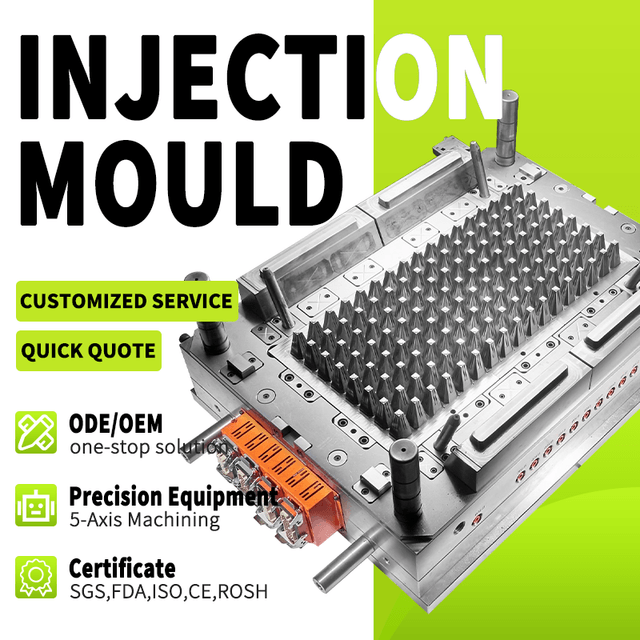

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

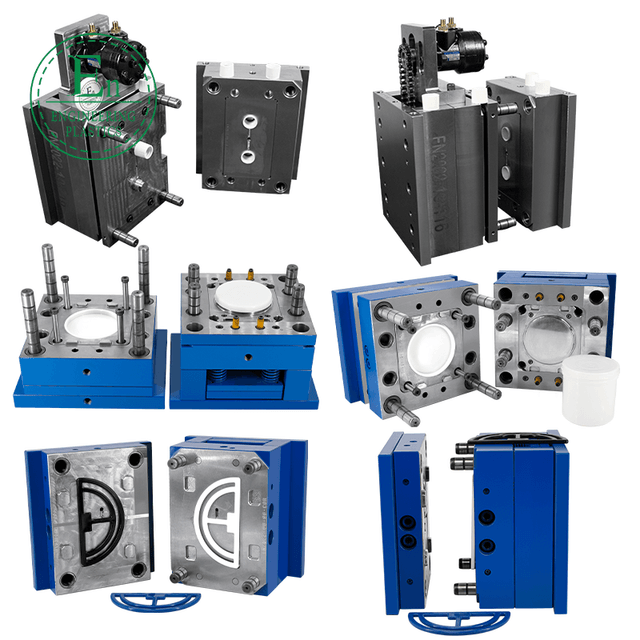

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Injection molding foam represents a significant advancement in the manufacturing industry, particularly when it comes to crafting cutting-edge products like the drone frame from Guangdong Engineering Plastics Industries Group Co., Ltd. This advanced technique involves injecting a foam material into a mold to create components that are lightweight yet resilient, ensuring durability and performance, which is crucial for any aerial adventure enthusiast.

In the realm of injection molding automotive applications, this method is gaining popularity due to its ability to produce components that are both strong and lightweight. In the automotive industry, where efficiency and performance are key, the utilization of injection molding foam for various parts helps reduce fuel consumption and improve overall vehicle performance. The same principles apply to the drone frame, highlighting the versatility of this technique across multiple sectors.

Guangdong Engineering Plastics Industries Group Co., Ltd. excels in leveraging sophisticated production methods, including injection mould China strategies. With over two decades of expertise, their senior engineers craft products using high-grade materials such as PEEK, PPS, and ABS, producing engineering marvels like the drone frame that showcase strength, stability, and aesthetic appeal. Moreover, their commitment to innovation, personalization, and comprehensive design ensures that clients receive products tailored to diverse needs and conditions.

The drone frame is a testament to their prowess in precision engineering. It is meticulously designed to offer optimal stability and seamless flight dynamics, making use of advanced injection molding foam techniques to enhance its lightweight yet formidable structure. This robustness is particularly invaluable for mounting essential components like cameras and sensors, a necessity for filmmakers and scientific explorers alike.

In global markets, Guangdong Engineering Plastics Industries Group Co., Ltd. has established a strong reputation, with their products being sought after in countries like the USA, UK, and Germany. Through their commitment to quality and innovation, they continue to lead the way in the engineering plastics industry, offering products that exceed expectations and set benchmarks in durability and performance.

Whether your interest lies in automotive advancements or pioneering drone technology, injection molding foam presents a reliable solution to meet diverse requirements, underscoring the importance of combining structural integrity with cutting-edge design. For those who regard the sky not just as a limit but as a playground, products like the drone frame are indispensable in pursuing passion and curiosity, driven by the exceptional capabilities of Guangdong Engineering Plastics Industries Group Co., Ltd.