We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

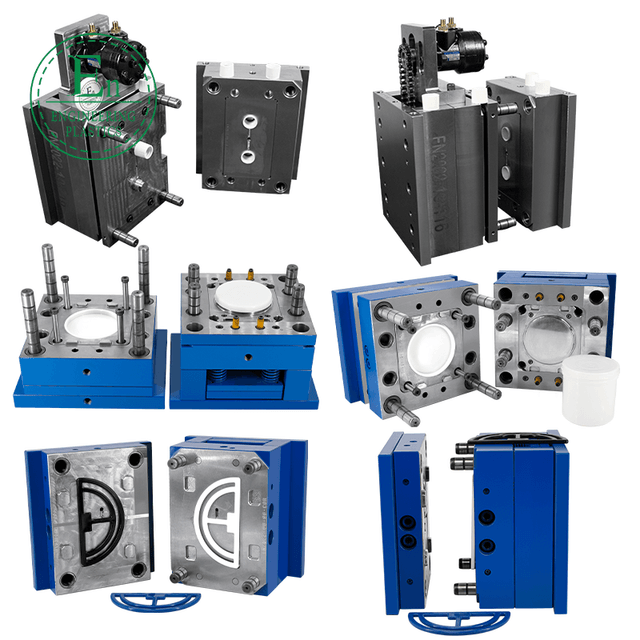

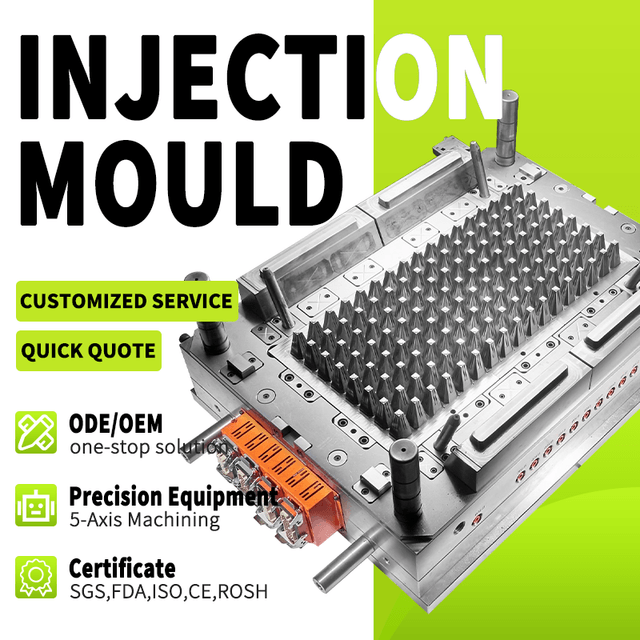

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the competitive landscape of automotive manufacturing, the presence of injection mould defects can lead to significant setbacks, compromising both component integrity and project timelines. At Guangdong Engineering Plastics Industries Group Co., Ltd., we understand that achieving perfection in plastic components is paramount. With a team of senior engineers boasting 15 to 25 years of specialized expertise, we have built our reputation on eliminating these very issues. Our approach combines advanced manufacturing technology with deep industry knowledge to produce a wide range of engineering plastic products, from intricate gears and pulleys to high-performance automotive parts, ensuring every piece meets the most stringent quality standards from the outset.

Our philosophy is that a superior final product begins long before the production phase; it starts with a meticulous injection molding design. This crucial initial step is where potential problems are anticipated and engineered out of the process. A proactive and intelligent design strategy directly influences the overall injection molding cost, not by cutting corners, but by preventing expensive tool modifications, reducing material waste, and minimizing cycle times. Our experienced team collaborates closely with clients, offering personalized customization and comprehensive research and development to optimize every aspect of the component's design for manufacturability, durability, and performance. This foresight is key to a cost-effective and successful production run.

This commitment to excellence is evident across our portfolio of advanced automotive components. Consider our sophisticated plastic grille inserts with their sleek honeycomb patterns; achieving this aesthetic without flaws requires a perfect injection molding design to ensure complete cavity fill and uniform cooling. Our robust automotive housing units, engineered to protect critical electronics, are a testament to precision, crafted to be free of warpage and sink marks that could compromise their protective function. From streamlined air vent panels that integrate seamlessly into dashboards to the vital internal framework components that enhance structural integrity, each part is a product of a carefully controlled process designed to prevent any injection mould defects.

Further strengthening our capabilities is our mastery over a diverse array of high-performance materials. The choice of material—be it PEEK, PPS, Nylon, ABS, or PTFE—is an integral part of the design process. Our engineers leverage their extensive knowledge to select the optimal polymer for each application, considering factors like thermal stability, chemical resistance, and mechanical stress. This careful selection is fundamental to preventing material-specific defects and ensuring the long-term reliability of the component. Our comprehensive R&D capabilities allow us to push the boundaries of what's possible, developing solutions that are not only functional but also lightweight and resilient.

As a trusted partner to clients across the globe, including in the USA, UK, Canada, and Germany, Guangdong Engineering Plastics Industries Group Co., Ltd. has earned a strong international reputation for quality and reliability. We deliver more than just parts; we provide peace of mind. By focusing on a superior initial design and leveraging decades of engineering experience, we effectively manage and reduce the total injection molding cost while delivering products of unparalleled quality. We invite you to discover how our state-of-the-art manufacturing systems and expert team can bring your most demanding automotive solutions to life, free from compromise and built for the future.