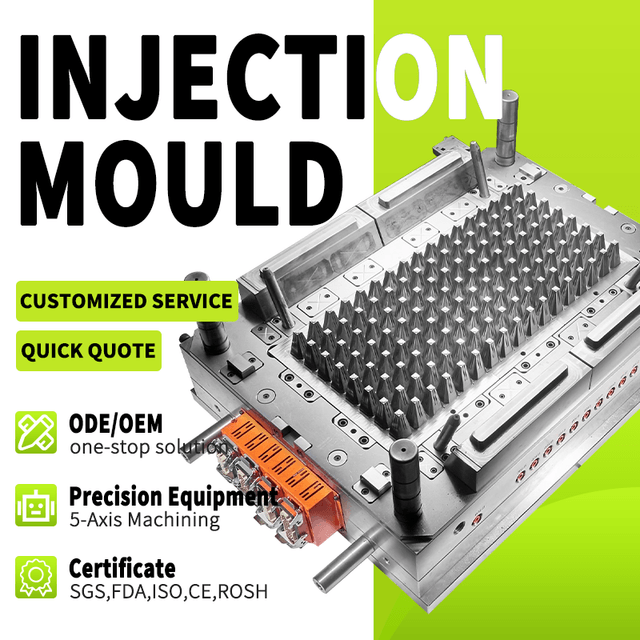

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

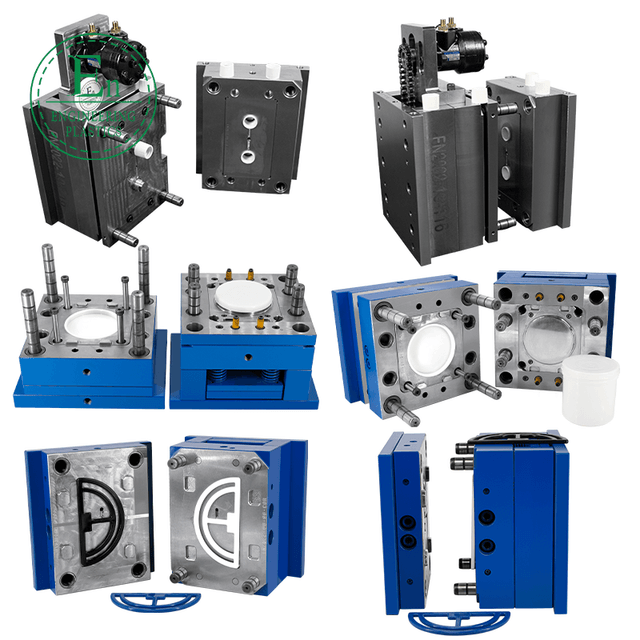

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In today's fast-paced industrial landscape, the demand for high-quality, durable, and precisely engineered components has never been greater. At Guangdong Engineering Plastics Industries Group Co., Ltd., we are at the forefront of this evolution, leveraging advanced manufacturing processes to deliver products that exceed expectations. Our commitment to excellence is rooted in a deep understanding of the sophisticated art of injection molding, a process we have refined through decades of experience. By combining innovative technology with the profound expertise of our senior engineers, we produce engineering plastic components that offer unparalleled performance and aesthetic quality, setting new standards for industries around the globe.

Central to our manufacturing prowess is our mastery of the injection molding hot runner system. This sophisticated technology represents a significant leap forward from conventional methods. A hot runner system maintains a molten pathway for the plastic from the machine nozzle directly into the mold cavities, eliminating the solid plastic runner that is ejected with the part in traditional cold runner systems. This advanced injection molding technique provides numerous advantages, including drastically reduced material waste, faster production cycle times, and superior part consistency. The precise temperature control inherent to this method ensures optimal flow properties, resulting in flawless surfaces and dimensionally accurate components, every single time. Our team's ability to implement and optimize this process is a testament to their 15-25 years of dedicated expertise.

Our new range of engineering plastics showcases the tangible benefits of our refined production methods. Consider our striking light blue cylinder with vibrant green caps; its corrugated surface and lightweight yet resilient polyethylene construction are a direct result of a perfectly controlled injection molding process. Look to the sunshine yellow connector, where integrated metallic inserts are seamlessly and securely embedded, demonstrating a level of precision that ensures robust and reliable connections. The rich red disk combines high-impact resistance with intricate surface patterns, while the sturdy navy base module features a perfectly formed intrinsic thread for dynamic assembly. Each of these components, with their bold colors and flawless finishes, are a testament to what a superior injection molding technique can achieve, transforming functional parts into statements of technical finesse.

Our capabilities extend far beyond this new lineup. Guangdong Engineering Plastics Industries Group Co., Ltd. specializes in comprehensive design, research, and development to offer fully personalized customization. We work with a wide spectrum of high-performance materials, including PEEK, PPS, Nylon, ABS, and PTFE, to manufacture a diverse array of products such as gears, pulleys, sealing rings, and bearings. Whether you require a standard component or a completely bespoke solution, our team of seasoned engineers collaborates with you to transform your concepts into reality. We leverage the most effective manufacturing approach for your specific needs, ensuring the final product meets your exact specifications for performance, durability, and cost-effectiveness.

Our dedication to quality and innovation has earned us a strong global reputation. We proudly serve an international clientele, with our products being exported to the USA, UK, Canada, Germany, and many other nations. By continually investing in advanced systems like the injection molding hot runner, we not only enhance our production capabilities but also provide our clients with a distinct competitive advantage. Partner with Guangdong Engineering Plastics Industries Group Co., Ltd. to experience the pinnacle of engineering plastic manufacturing, where cutting-edge technology and deep-seated expertise converge to create extraordinary results.