We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

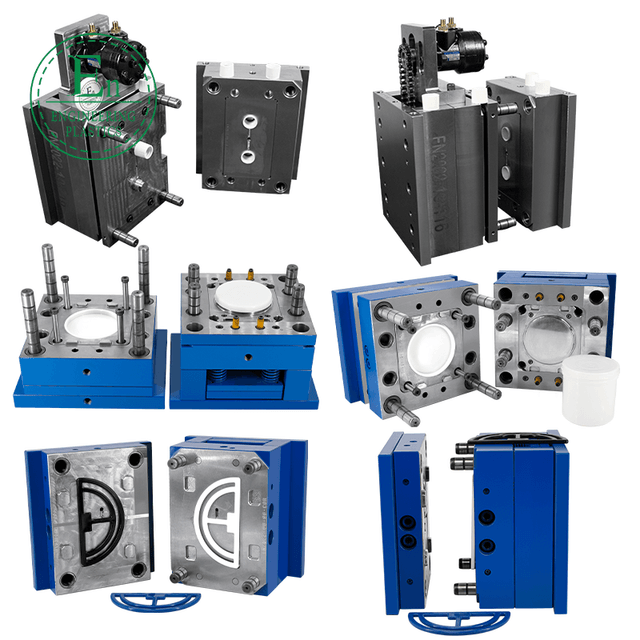

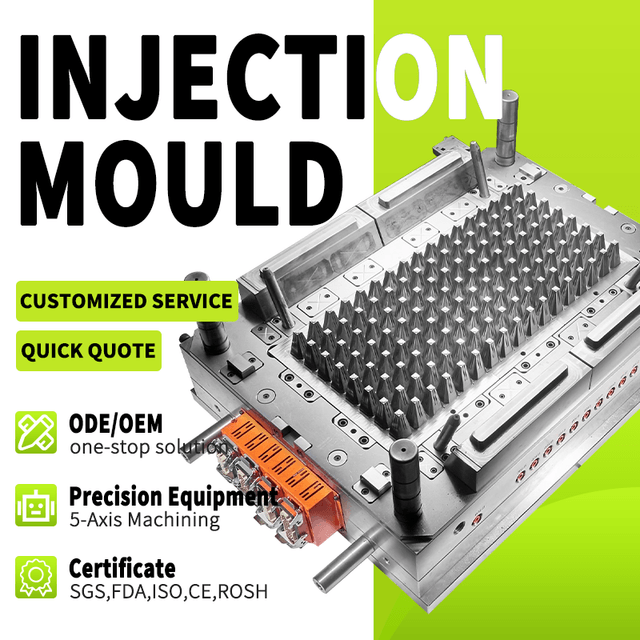

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

As a leading medical grade plastics manufacturer, we specialize in creating high-quality materials that meet the stringent demands of the healthcare industry, ensuring safety, durability, and reliability in every product. Our commitment to innovation drives us to develop advanced engineering plastics that not only adhere to medical standards but also enhance performance across various applications. At Guangdong Engineering Plastics Industries Group Co., Ltd., we pride ourselves on our team of senior engineers with 15-25 years of expertise, allowing us to provide personalized customization and comprehensive design solutions tailored to your needs.

Our engineering plastics are meticulously crafted to revolutionize industries beyond healthcare, positioning us as a trusted food grade plastic components supplier for applications requiring impeccable hygiene and safety. These components, made from materials like PEEK, PPS, Nylon, ABS, and PTFE, offer superior resistance to wear, fatigue, and environmental conditions, making them ideal for the food sector where contamination must be avoided at all costs. We manufacture a wide range of products, including gears, pulleys, sealing rings, and bearings, all designed for seamless integration into complex systems. This expertise extends to our role as an electronics plastic parts factory, where we produce lightweight, robust parts that enhance electronic devices with precision and longevity. By leveraging state-of-the-art molding techniques, we ensure that each piece not only performs exceptionally but also contributes to overall efficiency and sustainability.

In the realm of medical applications, our medical grade plastics manufacturer offerings are engineered for critical uses such as surgical instruments, implants, and diagnostic equipment, where precision and biocompatibility are paramount. We export our products to countries like the USA, UK, Canada, and Germany, building a strong global reputation for quality and reliability. Our materials are lightweight yet incredibly durable, reducing the weight of medical devices without compromising strength, which leads to better patient outcomes and operational efficiency. As a food grade plastic components supplier, we also cater to the needs of the food processing industry by providing components that resist chemicals and high temperatures, ensuring compliance with international safety standards and minimizing downtime in production lines.

Furthermore, as an electronics plastic parts factory, we innovate for the tech sector by developing parts that withstand electrical stresses and environmental factors, supporting the creation of advanced gadgets and machinery. Our comprehensive research and development capabilities allow us to offer customized solutions, whether it's for aerospace, automotive, or everyday consumer electronics. By choosing Guangdong Engineering Plastics Industries Group Co., Ltd., you're partnering with a company that not only delivers top-tier products but also fosters long-term relationships through exceptional service and innovation. This holistic approach ensures that our clients across various sectors benefit from materials that are not just functional but also future-proof, driving progress in an ever-evolving market. With our dedication to excellence, we continue to set benchmarks in the industry, making us your go-to medical grade plastics manufacturer for all your advanced material needs.