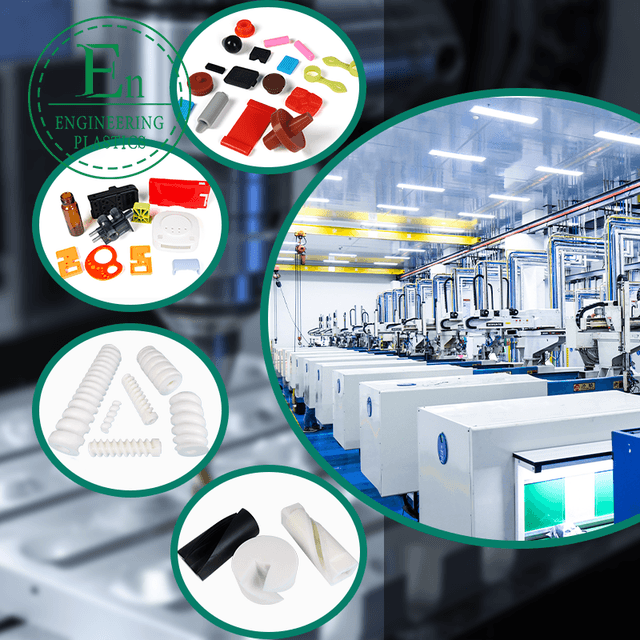

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

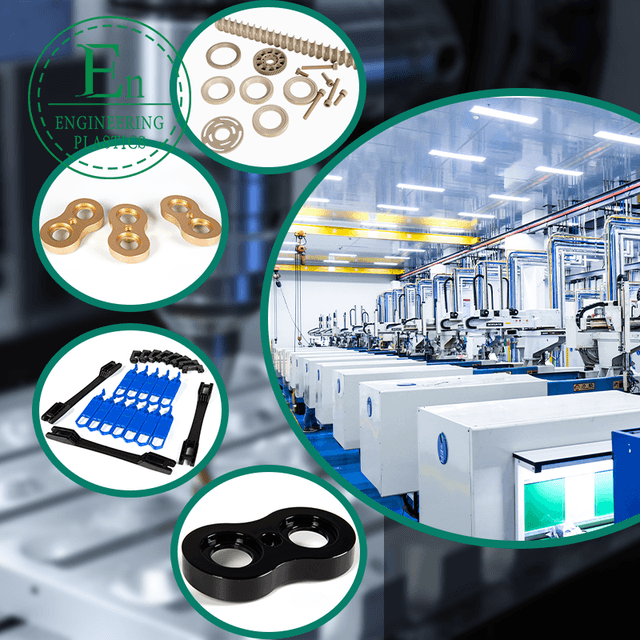

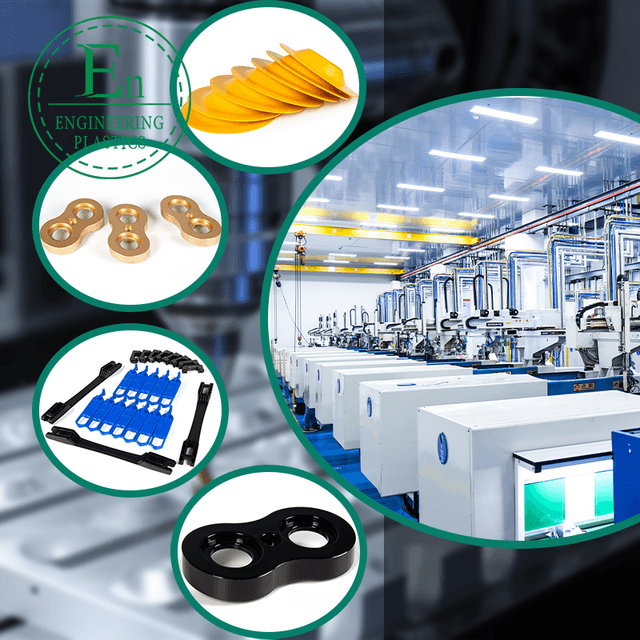

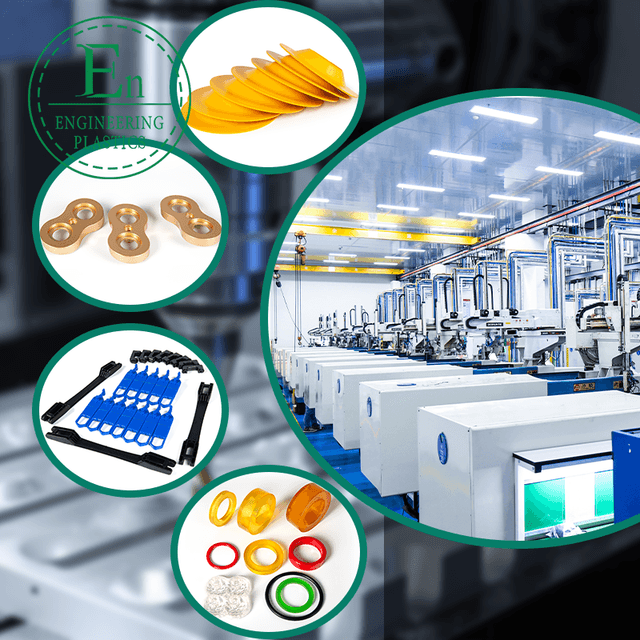

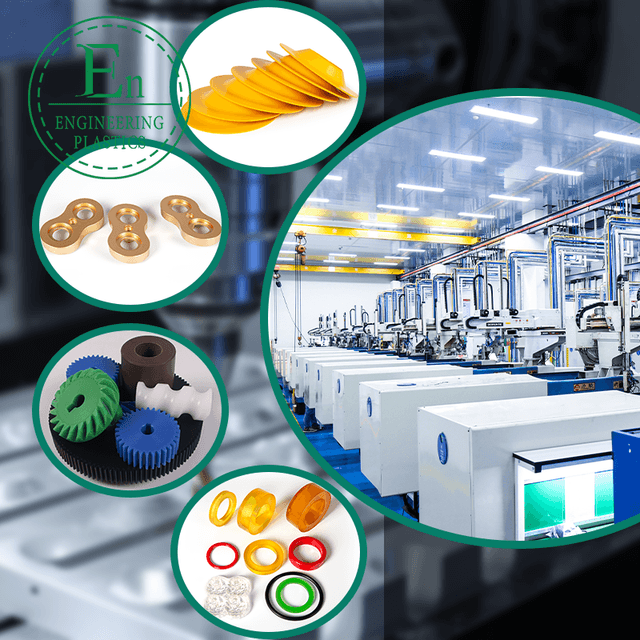

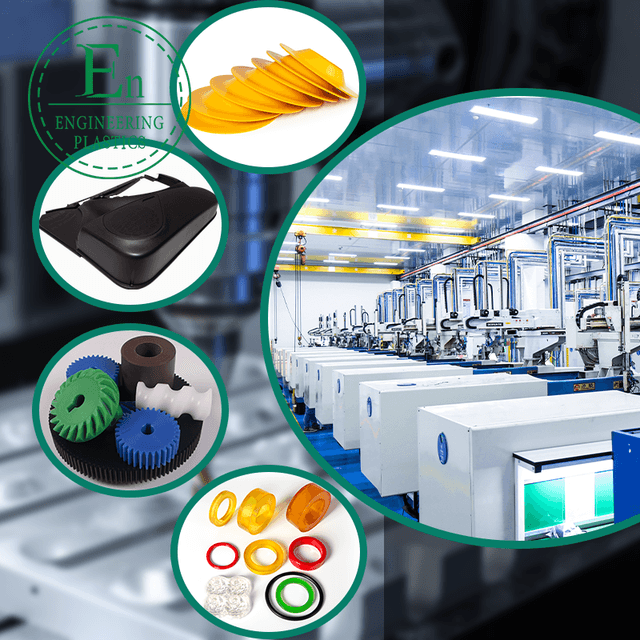

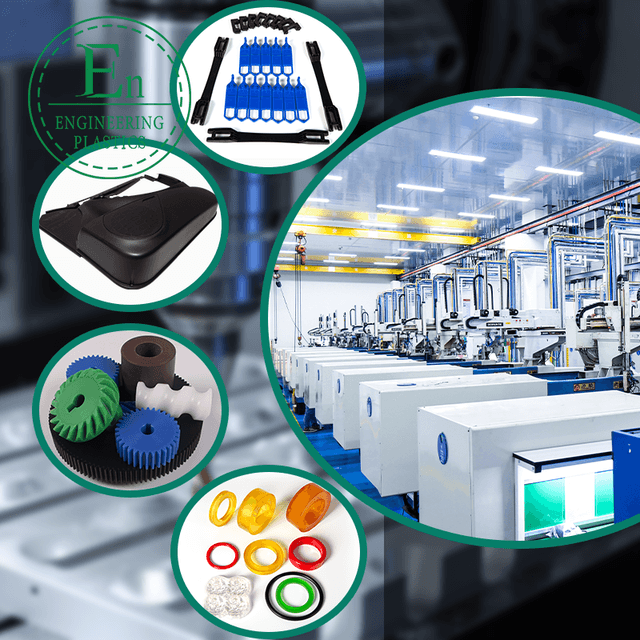

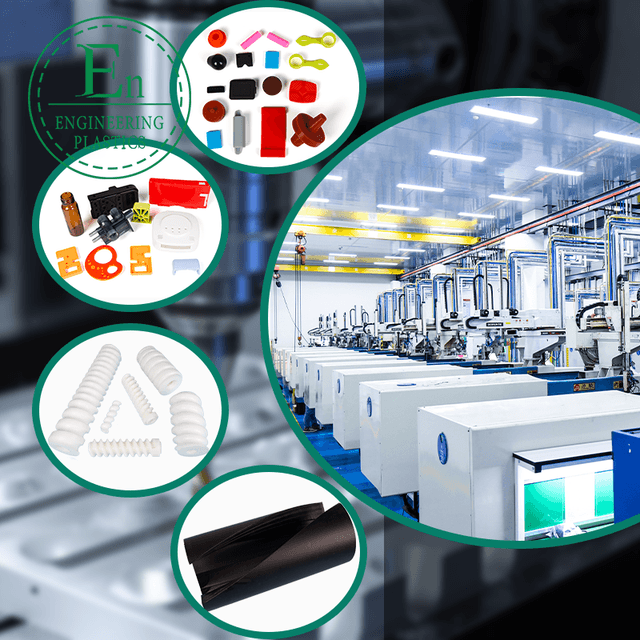

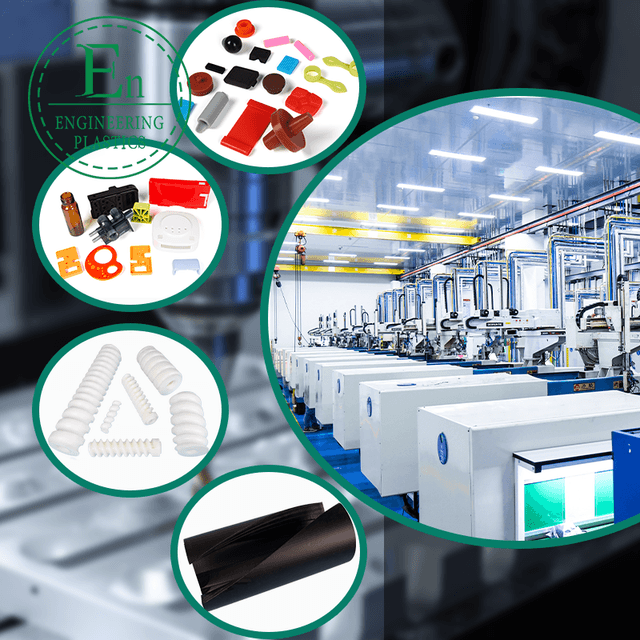

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

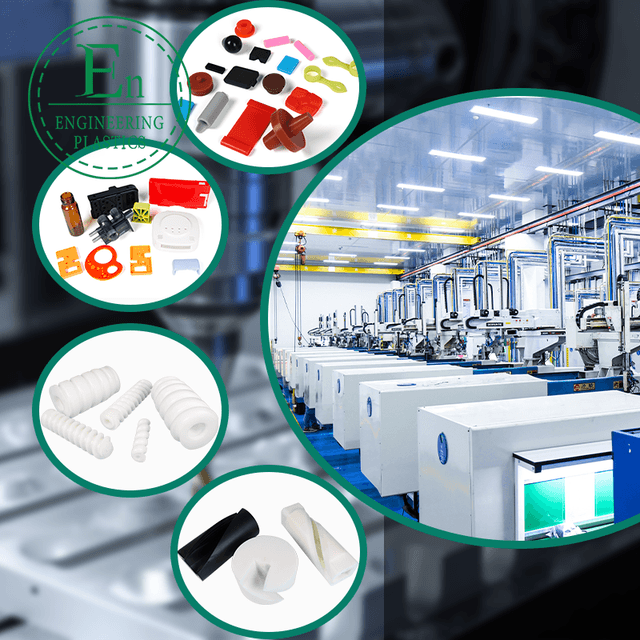

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

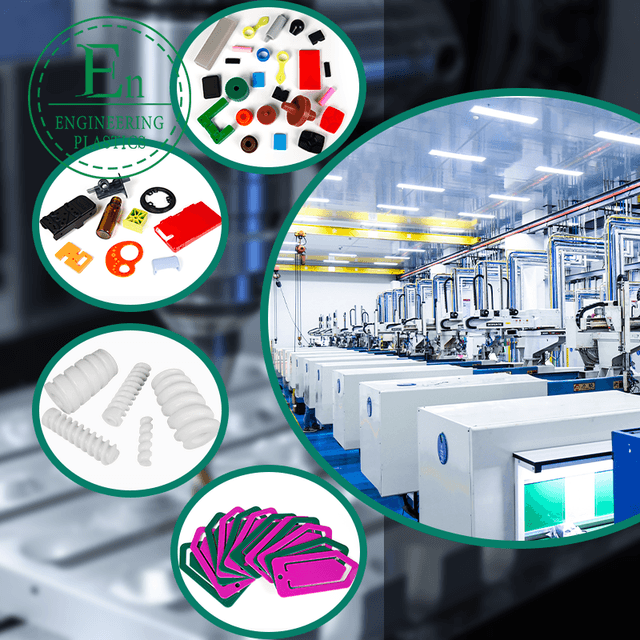

In the world of industrial manufacturing, abs molding stands out as a revolutionary technique that combines precision engineering with durable materials to create high-performance components. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage our state-of-the-art production lines to deliver abs molding solutions that redefine reliability and efficiency. Our expert team, boasting 15-25 years of experience, ensures every molded part meets the highest standards of quality and functionality. Whether you're in automotive, electronics, or any demanding sector, abs molding from our company provides the backbone for innovative designs that withstand extreme conditions.

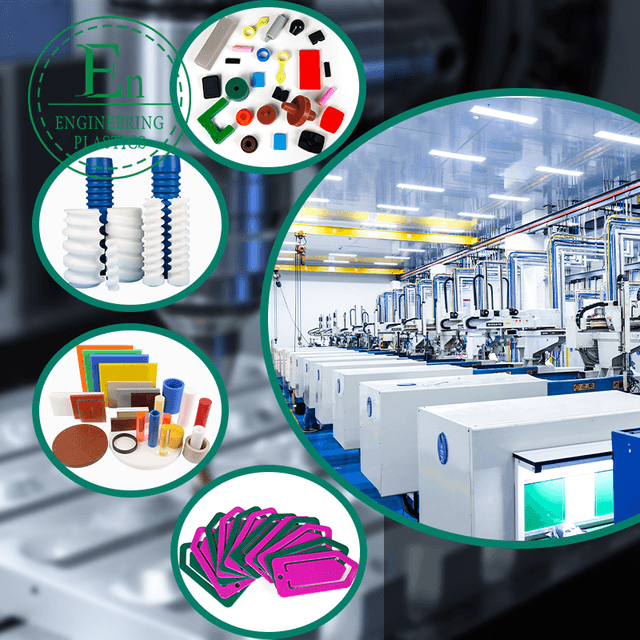

When it comes to mold custom services, we excel in tailoring solutions to your exact specifications, making us a trusted partner for global clients in the USA, UK, Canada, Germany, and beyond. Our comprehensive design, research, and development capabilities allow us to craft custom molds using advanced polymers like ABS, PEEK, PPS, Nylon, and PTFE. This mold custom approach not only optimizes strength-to-weight ratios but also incorporates recyclability for sustainable practices. From intricate gears and pulleys to sealing rings and bearings, our mold custom offerings ensure seamless integration into complex systems, enhancing performance while reducing environmental impact.

Complementing our expertise, we offer free shipping molds to make procurement effortless for international customers, underscoring our commitment to accessibility and customer satisfaction. Imagine receiving precisely engineered enclosures, frameworks, and fixtures without the hassle of logistics—our free shipping molds service covers exports worldwide, maintaining the integrity of each component from production to delivery. This benefit, paired with our robust abs molding processes, positions us as leaders in engineering plastics. Our products, such as sturdy cases ideal for high-demand applications, demonstrate exceptional durability and versatility, proving indispensable in industries requiring top-tier reliability.

Delving deeper into the benefits of our abs molding technology, it's engineered to provide superior resistance to heat, chemicals, and mechanical stress, making it perfect for everything from electronic housings to automotive parts. Our senior engineers collaborate closely with clients to refine mold custom designs, ensuring each iteration improves functionality and cost-effectiveness. With free shipping molds, we eliminate barriers, allowing businesses to focus on innovation rather than supply chain complexities. This holistic service model has earned us a stellar global reputation, as our engineering plastic products drive efficiency and sustainability across diverse applications.

As pioneers in the field, Guangdong Engineering Plastics Industries Group Co., Ltd. continues to push boundaries with abs molding innovations that blend practicality with cutting-edge design. Our diverse lineup, including precisely molded components like bearings and fixtures, showcases the pinnacle of polymer technology. By prioritizing mold custom personalization and offering free shipping molds, we empower industries to achieve more with less. Discover how our solutions can transform your projects—reliable, eco-friendly, and built to last, these engineering plastics are the future of manufacturing excellence.