We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

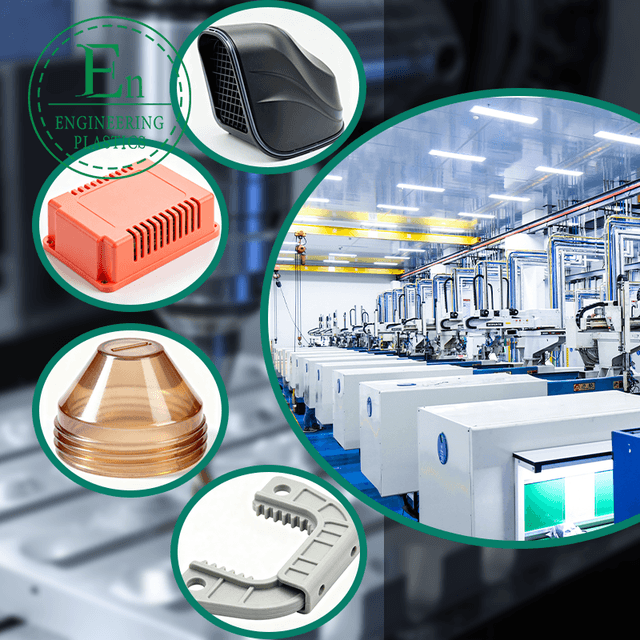

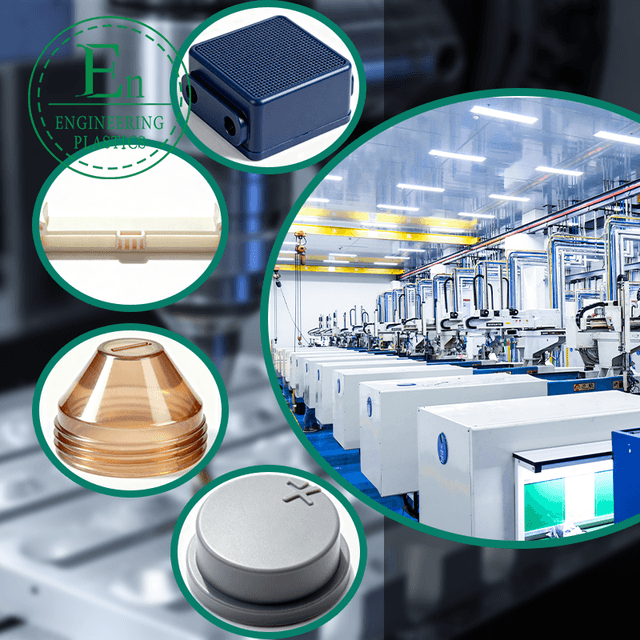

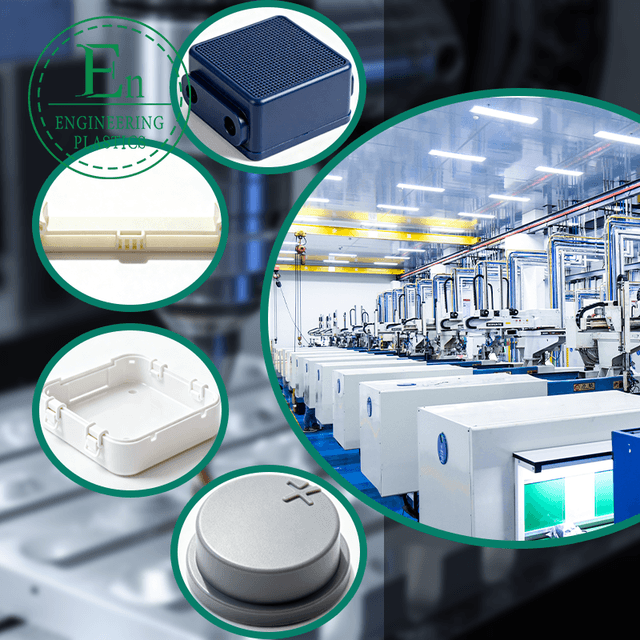

In the world of precision manufacturing, the case mold stands as a cornerstone for producing high-quality enclosures and components across various industries. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting advanced case molds that integrate seamlessly with our innovative engineering plastics solutions. These molds are designed to ensure unparalleled accuracy and efficiency, making them indispensable for creating durable plastic cases used in electronics, automotive parts, and consumer goods. Our commitment to excellence, backed by a team of senior engineers with 15-25 years of expertise, allows us to deliver case molds that meet the most stringent specifications, fostering reliability in every production run.

Delving deeper into our offerings, our case mold technology excels in applications requiring robust and versatile molding processes. For instance, when paired with injection molding die techniques, these molds enable the mass production of intricate plastic components like vibrantly colored enclosures and sealing rings. Our injection molding die designs are engineered from premium materials such as PEEK, PPS, and Nylon, ensuring resistance to high pressures and temperatures. This synergy not only enhances the durability of the final products but also streamlines manufacturing workflows, reducing downtime and costs for our clients worldwide. Whether you're in the USA, UK, or Germany, our exported solutions have earned a stellar reputation for their precision and adaptability, empowering businesses to innovate without compromise.

Innovation takes center stage with our exploration of 3D printed mould options, complementing traditional case mold production with cutting-edge rapid prototyping. The 3D printed mould approach allows for quick iterations and custom shapes, ideal for specialized needs like unique automotive seals or electronic housings. Utilizing advanced polymers such as ABS and PTFE, these molds offer exceptional wear resistance and thermal stability, mirroring the performance of our conventional injection molding die. At our state-of-the-art facility, we leverage comprehensive design and research capabilities to tailor 3D printed moulds that align perfectly with your project demands. This forward-thinking method not only accelerates development cycles but also opens doors to complex geometries that were once challenging to achieve, all while maintaining the high standards that define Guangdong Engineering Plastics Industries Group Co., Ltd.

Our case mold portfolio extends to a broad spectrum of engineering plastic products, including gears, pulleys, bearings, and custom-shaped parts, all produced with meticulous attention to detail. By combining injection molding die expertise with 3D printed mould innovations, we provide holistic solutions that cater to diverse industrial requirements, from consumer electronics to heavy machinery. Our global clientele benefits from personalized customization, ensuring that every case mold aligns with specific performance goals and regulatory standards. With a proven track record of exporting to Canada and beyond, we continue to push the boundaries of manufacturing technology, delivering products that withstand rigorous environments and contribute to sustainable practices.

Looking ahead, the evolution of case mold technology at our company promises even greater advancements in efficiency and sustainability. As we harness the full potential of injection molding die and 3D printed mould techniques, our engineering plastics remain at the forefront of industry innovation. Clients partnering with Guangdong Engineering Plastics Industries Group Co., Ltd. gain access to not just superior molds, but a reliable ally in achieving manufacturing excellence. Whether prototyping a new design or scaling production, our case molds ensure precision, reliability, and versatility, driving success in an ever-competitive market.