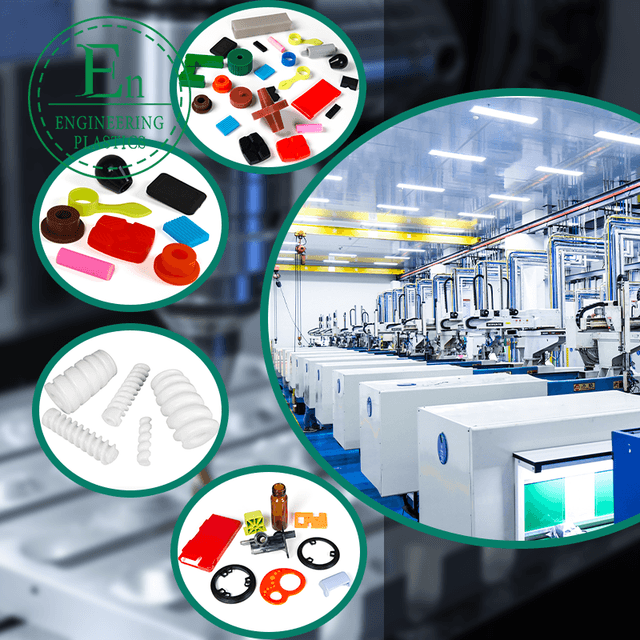

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, a high-quality cover mold is essential for producing durable and efficient components in various industries. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting advanced cover molds that integrate seamlessly with our injection moulding tooling processes. Our state-of-the-art production facility ensures that every cover mold meets the highest standards of accuracy and reliability, making it a cornerstone for businesses seeking superior engineering solutions.

Our cover molds are particularly renowned for their compatibility with pet injection mold technologies, allowing for the creation of versatile plastic parts that withstand demanding environments. With a team of senior engineers boasting 15-25 years of expertise, we offer personalized customization options that align perfectly with your project needs. Whether you're developing vibrant custom molded parts or specialized sealing components, our cover molds provide the precision required to enhance production efficiency. We utilize premium materials like PEEK, PPS, Nylon, ABS, and PTFE to guarantee longevity and performance in every mold we produce.

Delving deeper into our injection moulding tooling capabilities, our cover molds are designed to optimize the manufacturing of complex assemblies. For instance, in pet injection mold applications, these molds enable the production of intricate components that are both aesthetically pleasing and functionally robust. Our commitment to innovation means that each cover mold is engineered for minimal downtime and maximum output, serving a diverse range of sectors from automotive to electronics. Clients across the globe, including those in the USA, UK, Canada, and Germany, trust our injection moulding tooling for its proven track record in delivering high-performance results.

What sets our cover molds apart is the comprehensive design, research, and development support we provide. From initial concept to final prototyping, our experts collaborate closely with you to refine every detail of the pet injection mold process. This hands-on approach ensures that your cover mold not only fits your specifications but also elevates the overall quality of your end products, such as gears, pulleys, sealing rings, and bearings. By exporting to international markets, we've built a strong reputation for reliability and excellence, helping businesses worldwide achieve their engineering goals with confidence.

In summary, investing in our cover mold solutions means partnering with a leader in engineering plastics. Our injection moulding tooling and pet injection mold expertise translate into tangible benefits like reduced production costs and enhanced product durability. With over decades of collective experience, Guangdong Engineering Plastics Industries Group Co., Ltd. is dedicated to pushing the boundaries of what's possible in plastic molding. Contact us today to discover how our cover molds can transform your manufacturing processes and drive your projects to new heights of success.