We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

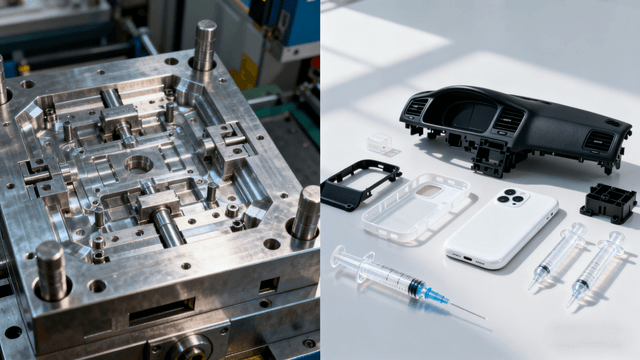

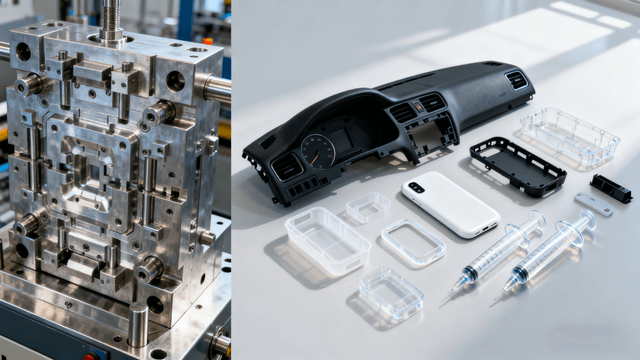

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

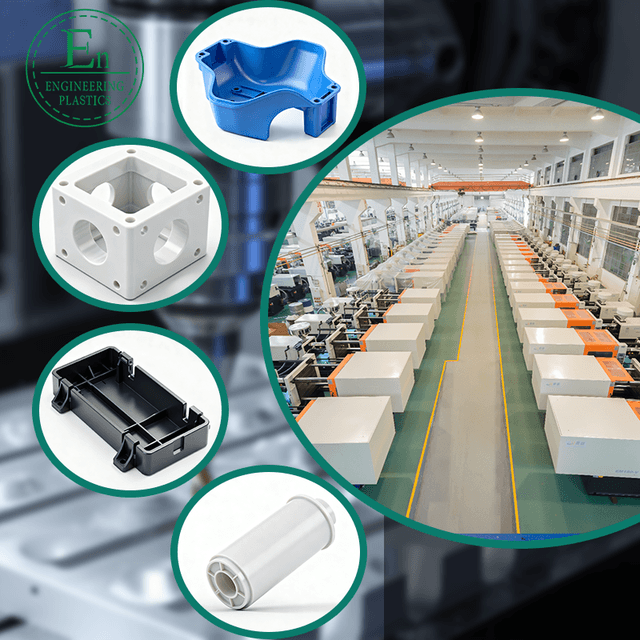

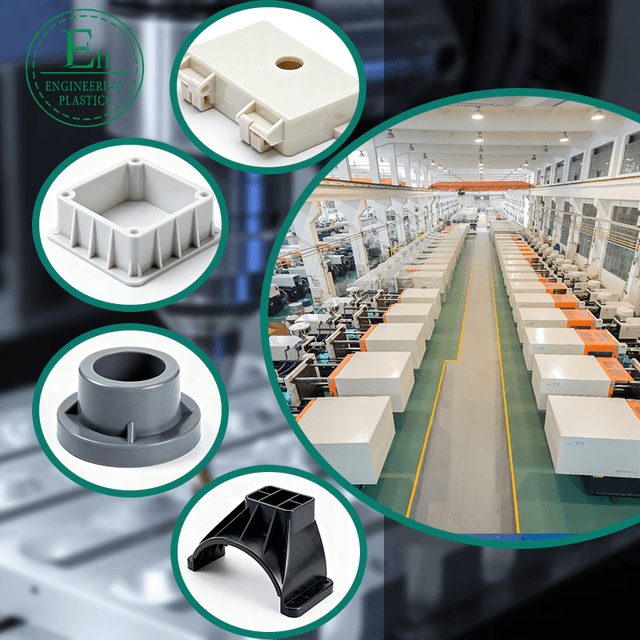

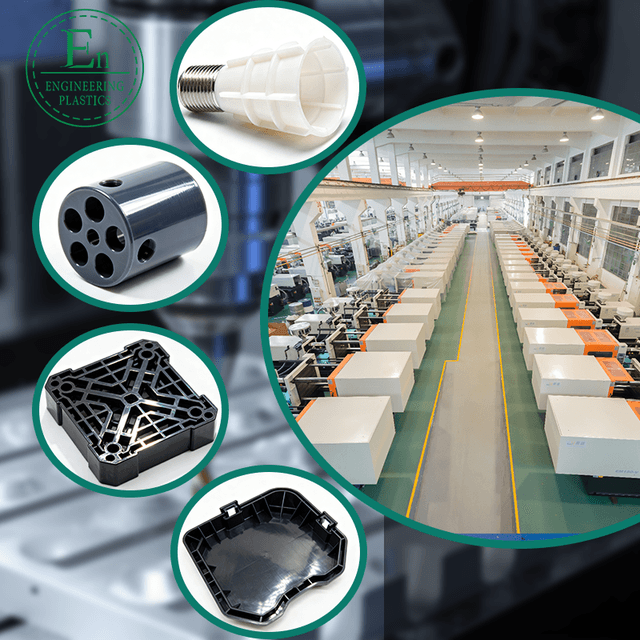

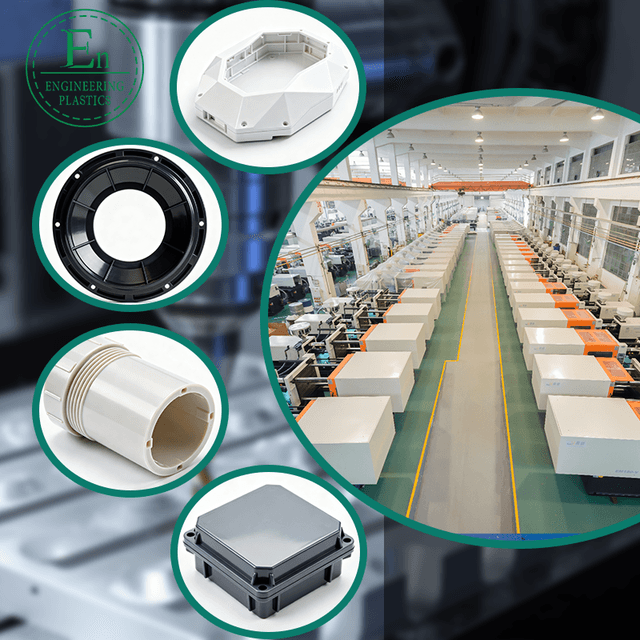

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

At Guangdong Engineering Plastics Industries Group Co., Ltd., we are pioneers in the creation of high-performance injection molding products that set new industry benchmarks for precision, durability, and innovation. With a legacy built on engineering excellence, our team leverages decades of expertise to deliver components that meet the most stringent requirements across various sectors. Our state-of-the-art manufacturing facility is the heart of our operation, where advanced technology and meticulous craftsmanship converge to produce parts that are not only functional but also aesthetically superior. We understand that in today's competitive market, quality is non-negotiable, and our commitment to it is evident in every single product that leaves our production line.

Our extensive portfolio showcases the remarkable versatility of our capabilities. We manufacture a wide array of injection molding parts, each designed for specific high-stress environments and applications. By utilizing premium engineering plastics such as PEEK, PPS, Nylon, ABS, and PTFE, we can produce components like gears, pulleys, sealing rings, and bearings that offer an optimal blend of strength, lightweight properties, and exceptional wear resistance. Whether it's an ergonomic blue component designed for both practicality and visual appeal or robust black and white parts engineered for industrial machinery, our products provide unparalleled reliability. This precision is especially critical in demanding fields like the automotive and aerospace industries, where exact measurements and dependable performance are paramount.

The foundation of our superior output is our mastery of the mould plastic injection process. This sophisticated technique allows us to create complex geometries and intricate designs with incredible consistency and accuracy. Our expansive, cutting-edge facility is equipped with precision machinery and operates under strict quality control protocols, ensuring that every batch meets the highest standards. This high-capacity production capability enables us to fulfill bulk orders efficiently without ever compromising on the quality that our clients have come to expect. Our process is a synergy of technology and human expertise, guaranteeing that each component is perfectly formed to enhance both functionality and value.

What truly distinguishes Guangdong Engineering Plastics Industries Group Co., Ltd. is our dedicated team of senior engineers, who bring 15 to 25 years of specialized experience to the table. Their deep understanding of material science and the nuances of the mould plastic injection technique allows us to offer more than just manufacturing. We provide comprehensive design, research, and development services, working closely with clients to develop personalized and custom solutions. This collaborative approach ensures that the final injection molding parts are perfectly tailored to their unique application, solving complex challenges and driving efficiency for their operations.

Our reputation for excellence in producing top-tier injection molding products extends globally, with a strong and growing presence in international markets including the USA, UK, Canada, and Germany. This global footprint is a testament to the trust our clients place in our quality and reliability. We are not just a supplier; we are a strategic partner dedicated to your success. When you choose us, you are choosing a company committed to pushing the boundaries of what is possible with engineering plastics, delivering innovative solutions that provide a competitive edge. Embrace the future of engineering with components crafted by true experts in the field.