We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

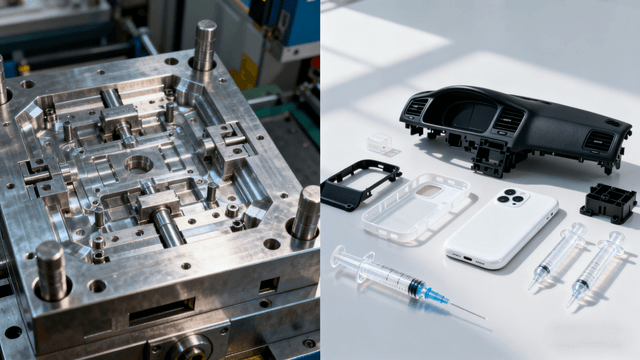

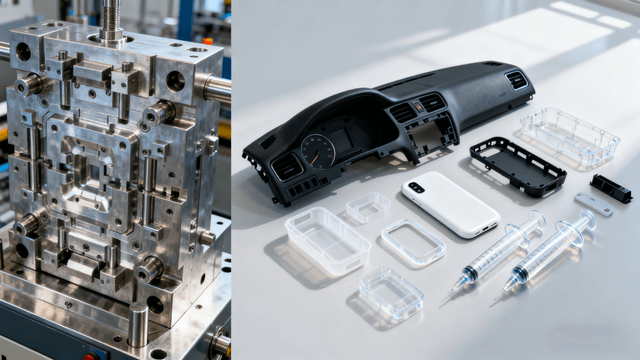

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

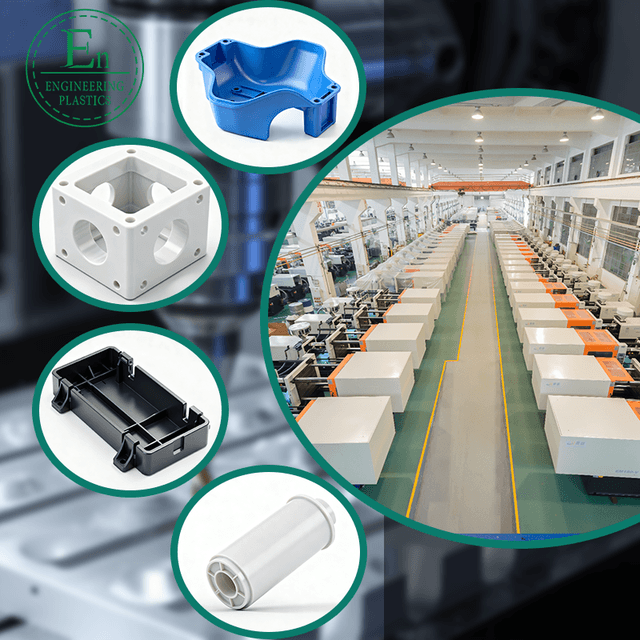

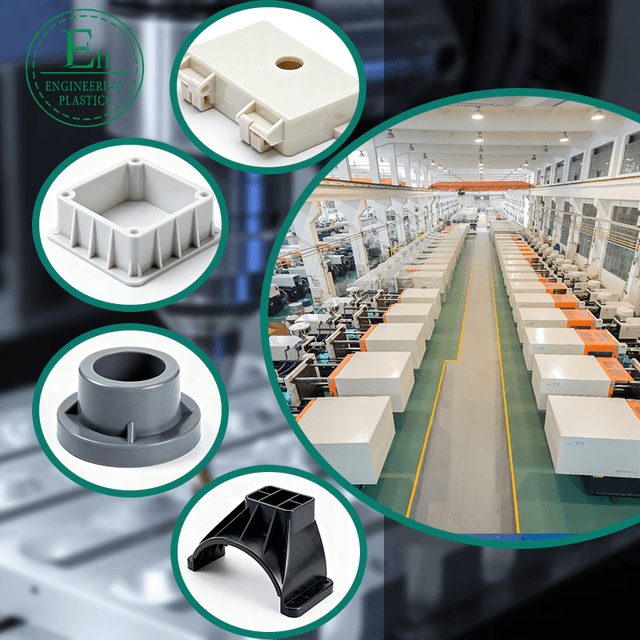

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of modern manufacturing, precision and efficiency are paramount. Guangdong Engineering Plastics Industries Group Co., Ltd. stands at the forefront of this evolution, offering a premier injection moulding service that transforms complex designs into high-quality, tangible products. Our process combines decades of engineering expertise with state-of-the-art technology to deliver components that meet the most stringent standards of performance and durability. Whether for intricate electronic enclosures or robust structural parts, our advanced manufacturing capabilities ensure every piece is crafted with unparalleled accuracy, setting a new benchmark for the industry and providing our clients with a distinct competitive advantage.

Our reputation as a leading plastic mould manufacturer is built upon a foundation of deep technical knowledge and a relentless commitment to innovation. Our team is our greatest asset, comprising senior engineers with 15 to 25 years of specialized experience in the field. This wealth of expertise allows us to offer more than just manufacturing; we provide a comprehensive partnership that includes personalized customization, in-depth design consultation, and full-scale research and development. We work closely with our clients from concept to completion, ensuring the final product not only meets but exceeds their expectations. This collaborative approach makes us the preferred partner for companies seeking a reliable and expert plastic mould manufacturer.

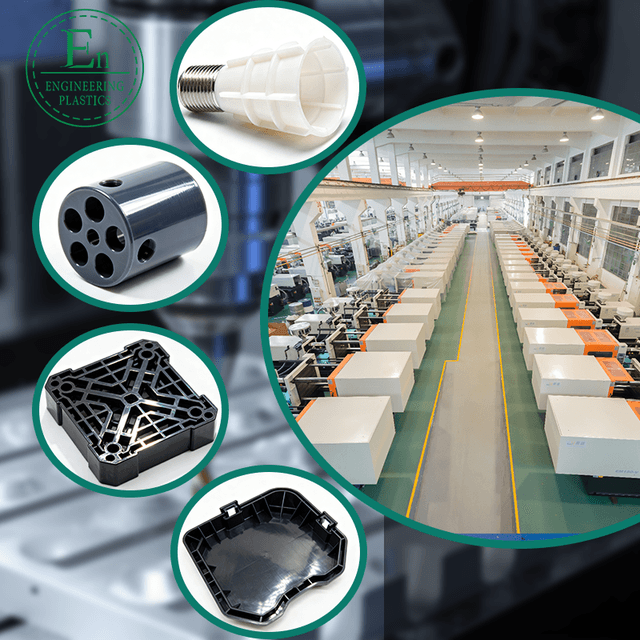

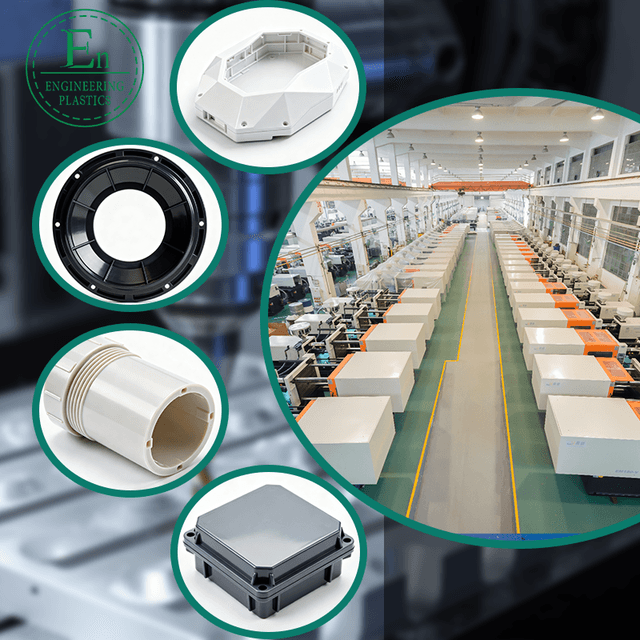

At Guangdong Engineering Plastics Industries Group Co., Ltd., we are a distinguished mold manufacturer capable of working with a diverse array of high-performance materials. Our proficiency extends across a wide spectrum of engineering plastics, including PEEK, PPS, Nylon, ABS, and PTFE. This versatility allows us to produce a vast range of products, from precision gears and pulleys to durable sealing rings and bearings. Our state-of-the-art facility is a testament to our commitment to quality, where advanced injection moulding machinery and meticulous craftsmanship converge. This synergy ensures that every component, regardless of its complexity or material, is produced with exceptional consistency and adheres to the highest quality control standards.

Our extensive product portfolio showcases the breadth of our capabilities. We engineer robust enclosures designed to shield sensitive electronic systems from external impacts, and versatile structural housings built with reinforced materials for applications demanding superior strength and resilience. Our precision-engineered couplings feature meticulously crafted lines for seamless operation in mechanical assemblies, while our innovative support brackets offer a perfect blend of sleek design and maximum stability for various mounting solutions. This diverse range highlights our ability as a proficient mold manufacturer to tackle any challenge and deliver solutions that are both functional and innovative, engineered with sustainability and reliability in mind.

While we are rooted in advanced engineering, our vision is global. Guangdong Engineering Plastics Industries Group Co., Ltd. proudly serves a wide international client base, with our products being exported to major markets including the USA, UK, Canada, and Germany. This global reach has earned us a strong reputation for excellence and reliability on the world stage. We are equipped to handle both customized, small-batch orders and large-scale production runs with the same commitment to speed, accuracy, and quality. When you partner with us, you are choosing a future-focused company dedicated to pushing the boundaries of what is possible in engineering plastics and injection moulding.