We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

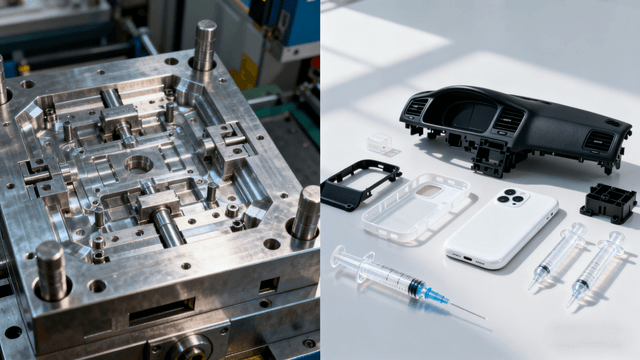

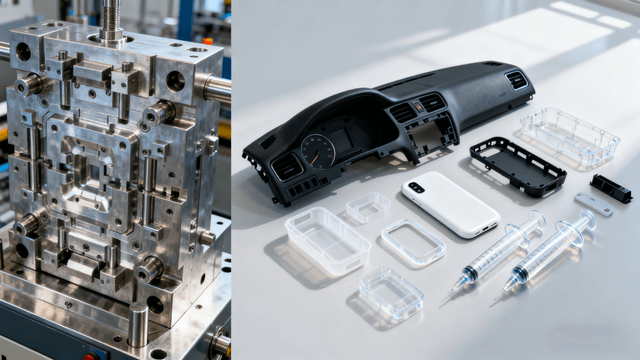

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

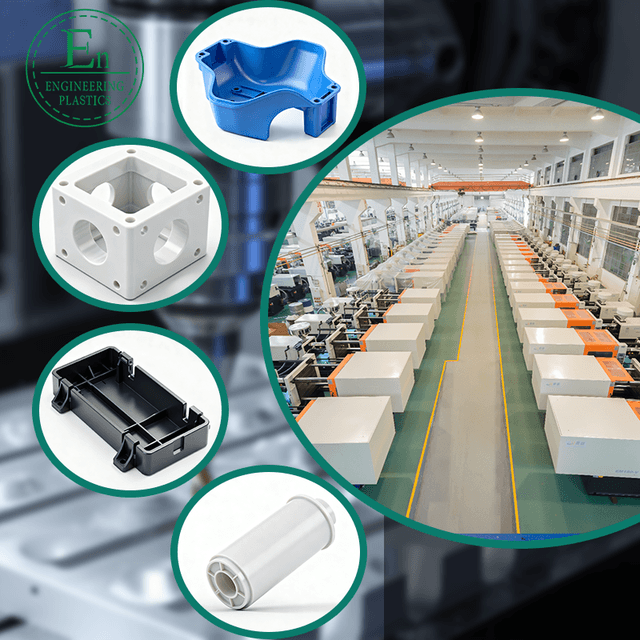

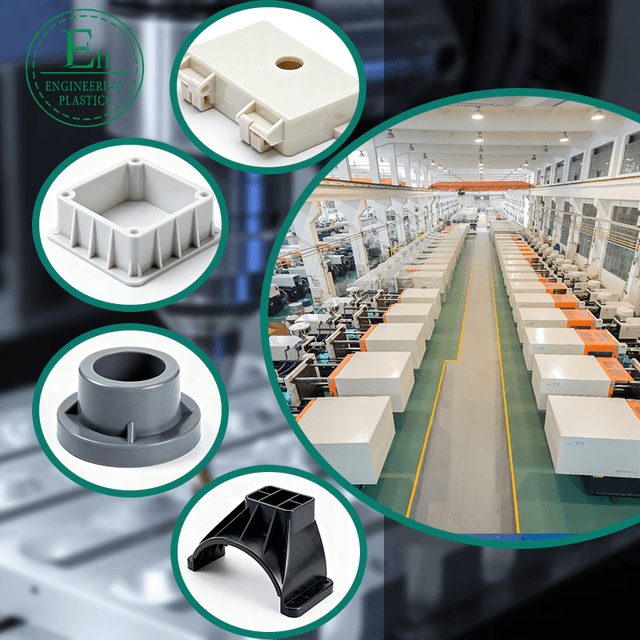

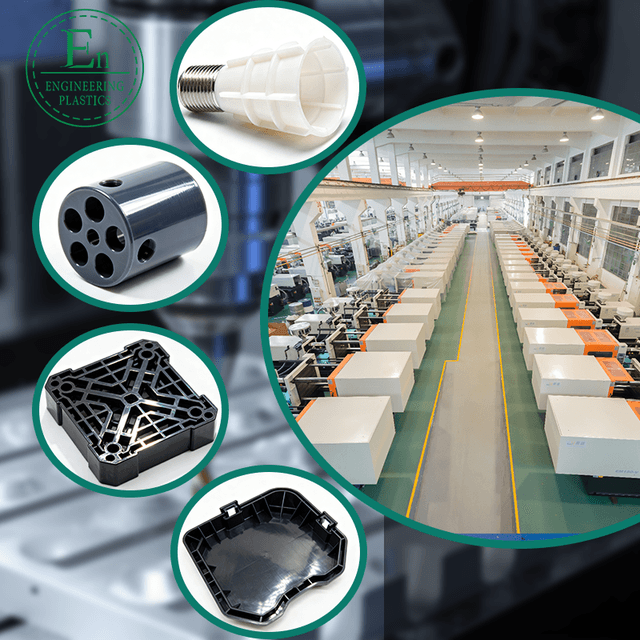

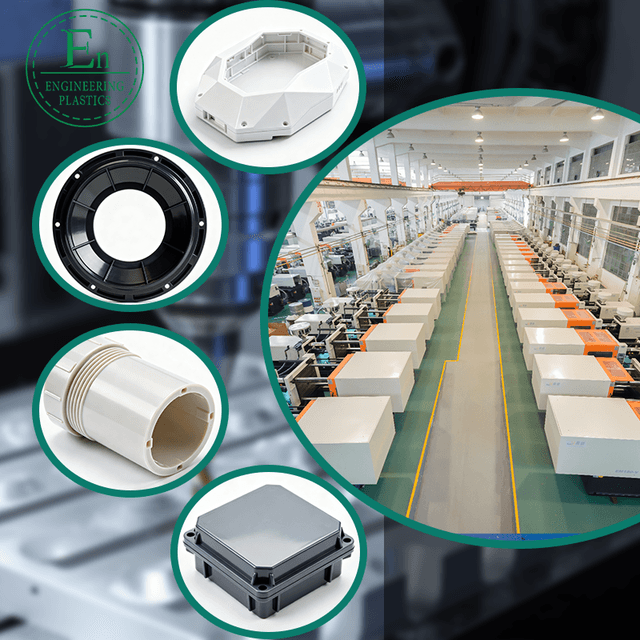

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

At Guangdong Engineering Plastics Industries Group Co., Ltd., we have mastered the art and science of mold plastic injection, a cutting-edge manufacturing process that serves as the foundation for modern industrial innovation. This technology allows us to transform high-performance raw materials into intricately designed components with unparalleled precision and consistency. Our commitment is to deliver engineering plastics that are not just parts, but the very backbone of advanced applications across a multitude of sectors. With a team of seasoned experts, we leverage this process to create solutions that meet the high-stakes demands of today’s fast-paced technological world, ensuring every product we craft embodies quality, durability, and superior performance from the very first design.

Our extensive portfolio showcases a diverse collection of plastic injection moulding parts, each meticulously engineered to fulfill specific functions while upholding the highest standards of quality. This assortment includes everything from ergonomically designed grips and handles that offer maximum comfort without sacrificing strength, to ultra-resilient housings and casings built to protect sensitive internal components in the harshest environments. We offer extensive customization options, reflected in the vibrant array of colors available, ensuring that your product’s aesthetic and brand identity are enhanced without any compromise on functionality. Whether you require gears, pulleys, sealing rings, or bearings, we utilize premium materials like PEEK, PPS, Nylon, ABS, and PTFE to manufacture components that set new benchmarks for excellence.

What sets us apart is our role as a comprehensive solutions provider and expert mold supplier. Our strength lies in our team of senior engineers, who bring 15 to 25 years of dedicated expertise to every project. This wealth of experience enables us to offer personalized customization and in-depth support throughout the entire product lifecycle, from initial design and research to final development and manufacturing. We don't just produce parts; we collaborate with our clients to solve their most complex engineering challenges. Our global reputation is built on this partnership approach, with a strong track record of serving clients in the USA, UK, Canada, Germany, and beyond, proving our capability to manage and deliver on international projects with professionalism and trust.

Our precision-engineered components are the silent enablers of excellence in some of the world's most demanding industries, including automotive, electronics, and consumer goods. The reliability of our plastic injection moulding parts is critical, whether they are small fastening clips or complex structural elements. By using a refined mold plastic injection process, we ensure that every component, from our transparent aesthetic pieces to our solid structural parts, delivers consistent performance and resilience against wear and tear. Furthermore, we are committed to blending innovation with environmental responsibility by utilizing recyclable materials, helping our clients achieve their sustainability goals while pushing the boundaries of what's possible.

Choosing Guangdong Engineering Plastics Industries Group means partnering with a leading mold supplier dedicated to pushing the envelope of quality and design. We invite you to explore a future where ingenuity and versatility converge seamlessly, powered by our advanced engineering plastics. Our team is ready to help you turn your ambitious concepts into tangible realities, providing components that are not only built to last but are also engineered for excellence. Join us in embracing a new standard of manufacturing where precision, innovation, and client partnership come together to create truly exceptional products.