We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

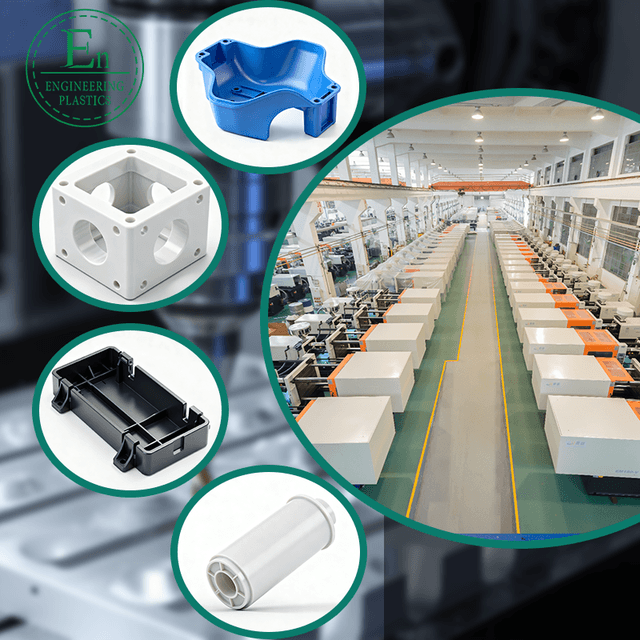

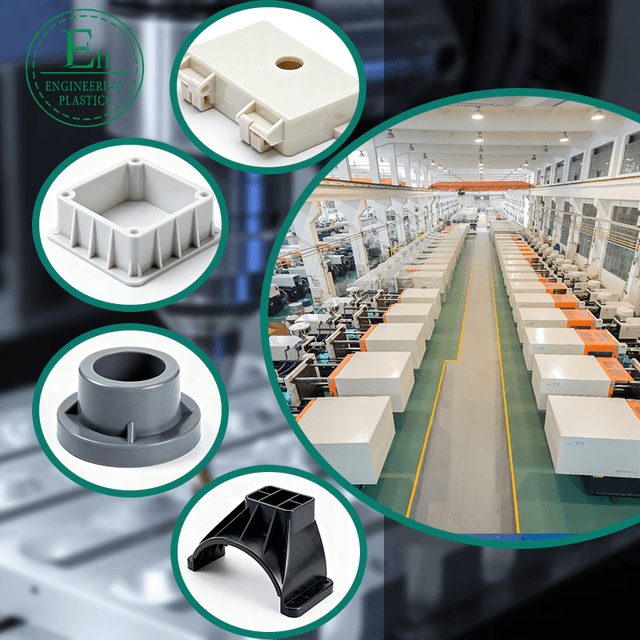

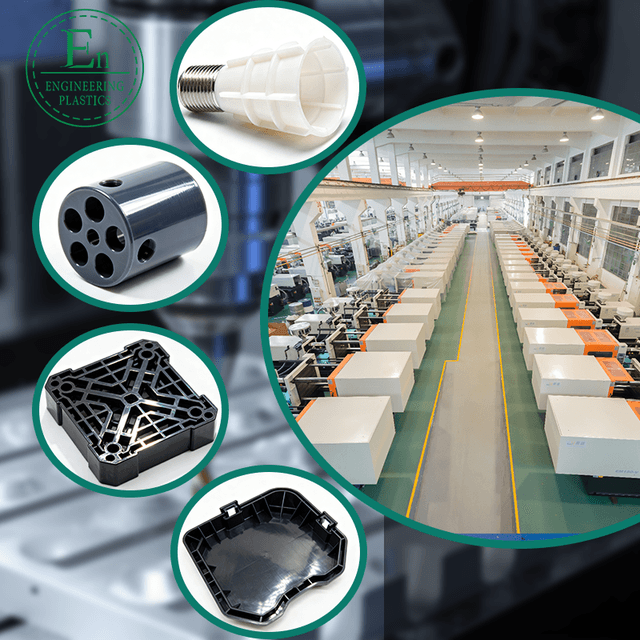

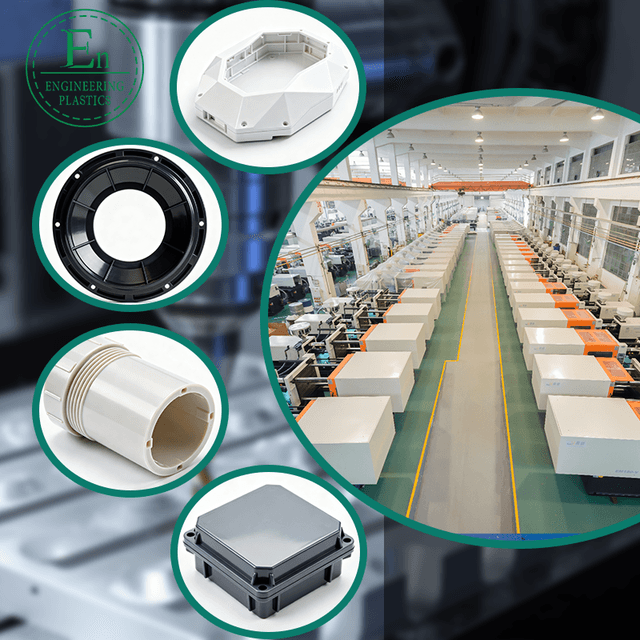

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the competitive landscape of modern manufacturing, superior plastic injection mold design is the cornerstone of success, transforming raw materials into the intricate and durable products that power our world. At Guangdong Engineering Plastics Industries Group Co., Ltd., we understand that the quality of the final component is determined long before the first gram of plastic is injected. It begins with an intelligent, robust, and meticulously engineered mold. Our team, composed of senior engineers with 15 to 25 years of dedicated expertise, provides the foundation for excellence, offering comprehensive design, research, and development capabilities that set the industry standard for innovation and reliability.

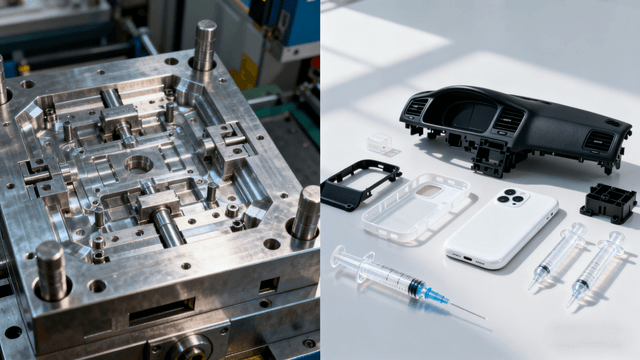

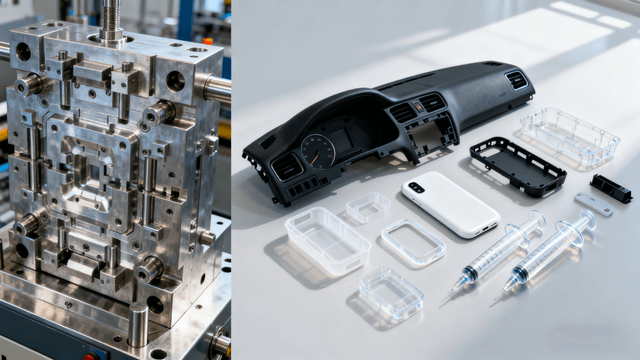

A critical element of this process is the creation of a precision mould. This is not merely a tool, but a piece of high-tech craftsmanship that dictates the final product's dimensions, finish, and structural integrity. Our engineers leverage their extensive experience to craft molds with microscopic accuracy, ensuring that every part produced is a perfect replica of the design, from the sleek contours of a smartphone case to the critical dimensions of a medical-grade syringe. This level of precision is paramount in demanding sectors like automotive and healthcare, where components like dashboard panels must be both aesthetically pleasing and resilient, and medical devices must adhere to the highest standards of safety and hygiene. The ability to work with advanced engineering plastics such as PEEK, PPS, and Nylon further showcases our capability to handle complex material properties within a finely-tuned plastic molding injection process.

The effectiveness of the entire plastic molding injection cycle hinges on the quality and design of the mold. A well-designed mold from our facility ensures optimal material flow, rapid and uniform cooling, and seamless part ejection. This translates directly into tangible benefits for our clients, including reduced cycle times, minimized material waste, and exceptional consistency across high-volume production runs. Whether we are producing crystal-clear containers for consumer use or complex internal gears and pulleys for industrial machinery, the initial investment in a superior precision mould pays dividends through enhanced efficiency and unparalleled product quality. This versatility demonstrates our capacity to deliver solutions that are not only functional but also elevate everyday experiences through thoughtful engineering.

At Guangdong Engineering Plastics Industries Group Co., Ltd., we pride ourselves on being more than just manufacturers; we are partners in innovation. We collaborate closely with our clients, offering personalized customization services to bring their unique visions to life. Our R&D capabilities allow us to tackle the most challenging projects, developing novel solutions and optimizing existing designs for better performance and cost-effectiveness. This client-centric approach has earned us a strong global reputation, with a growing list of satisfied partners in the USA, UK, Canada, Germany, and beyond who trust our expertise in plastic injection mold design to give them a competitive edge in the marketplace.

Ultimately, the journey from a raw polymer to a finished, functional product is defined by the quality of its beginnings. Our unwavering commitment to excellence in plastic injection mold design ensures that every component we help create, from sealing rings to bearings, meets the highest international standards of quality, durability, and performance. By blending decades of engineering experience with cutting-edge technology and a deep understanding of advanced materials, we empower our clients to redefine what’s possible. Trust in our expertise to be the catalyst for your next successful product launch, confident in a partnership that values precision and innovation above all else.