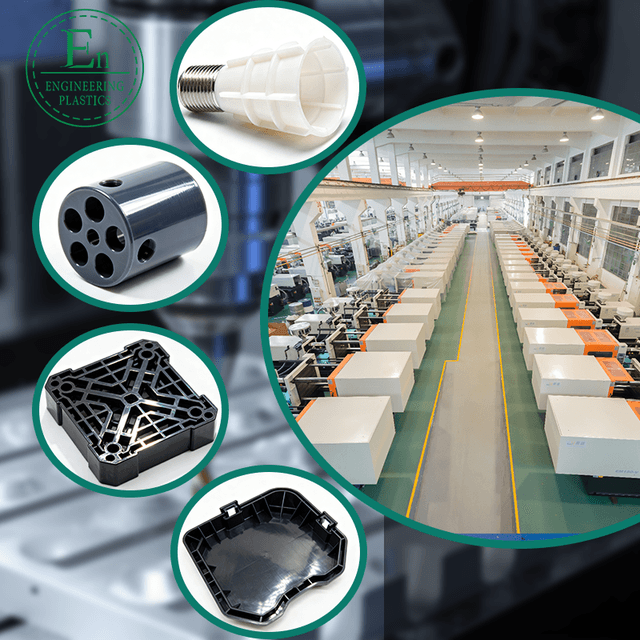

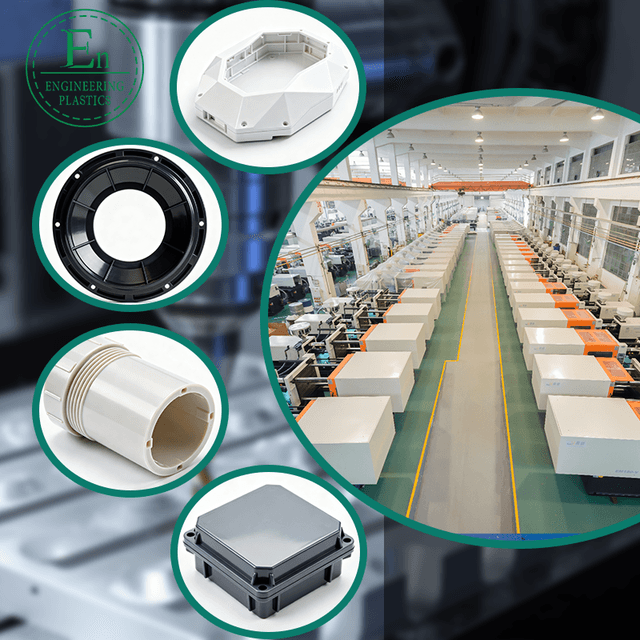

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

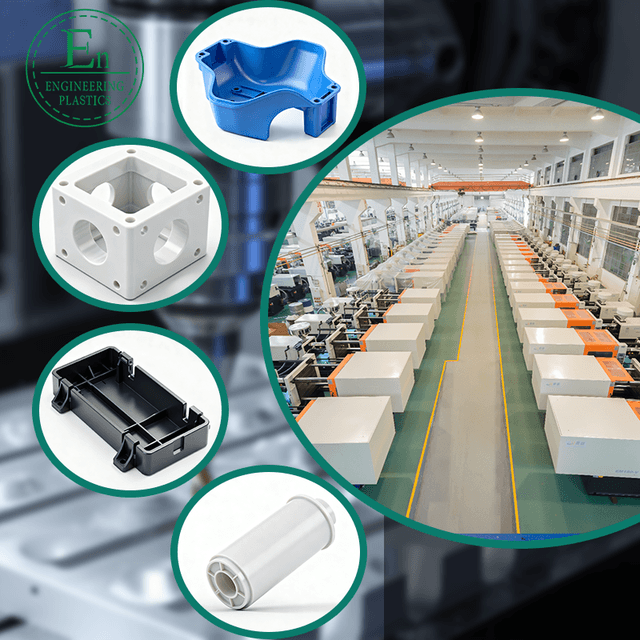

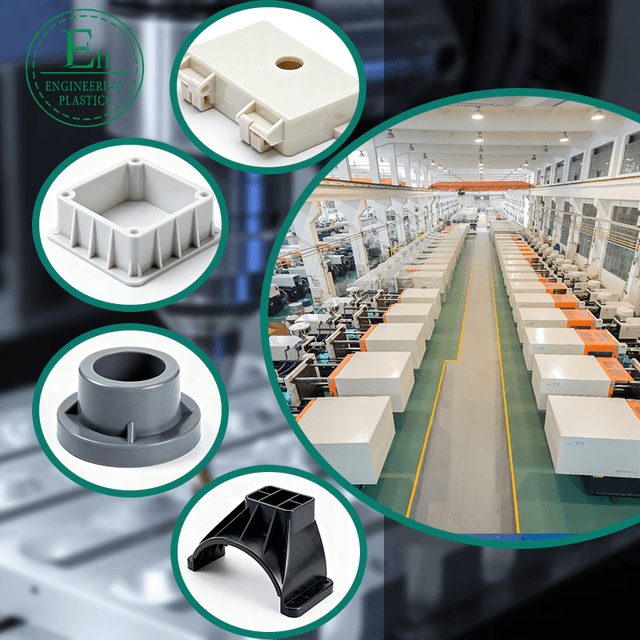

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In today's competitive manufacturing landscape, securing a reliable plastic moulding service is fundamental to transforming innovative concepts into tangible, high-quality products. This process is the cornerstone of modern production, enabling the creation of everything from complex industrial components to essential consumer goods with unparalleled precision and efficiency. At Guangdong Engineering Plastics Industries Group Co., Ltd., we harness the full potential of advanced molding technology to deliver solutions that meet the most demanding specifications, ensuring that every product we help create is built for performance and longevity.

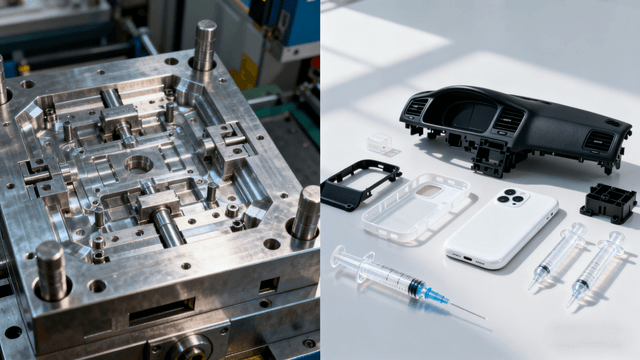

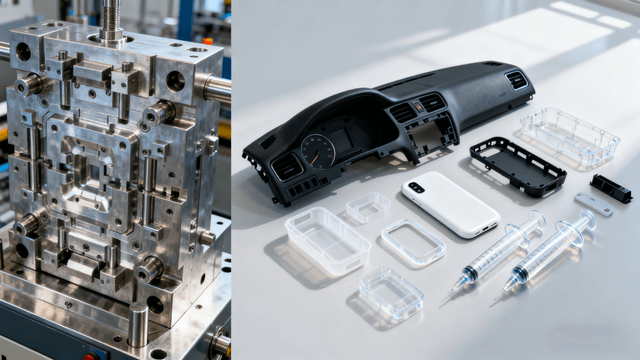

At the core of our operations is the sophisticated technique of injection plastic molding. This method is celebrated for its remarkable versatility and accuracy, allowing for the mass production of intricate parts with consistent quality. As seen in the diverse applications of our technology, we can craft finely detailed automotive components, such as dashboards that require a perfect fit and finish for modern vehicles. We also produce sleek, durable smartphone cases that balance aesthetics with protection, and critical medical supplies like syringes, where precision and sterility are non-negotiable. The injection plastic molding process ensures that each item, regardless of its complexity or industry, adheres to the highest standards of structural integrity and design fidelity.

Choosing the right partner from the many mould companies available is a critical decision that directly impacts the success of your project. What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our deep-seated expertise and commitment to collaborative innovation. Our team is composed of senior engineers who bring between 15 and 25 years of specialized experience to the table. This wealth of knowledge allows us to offer more than just manufacturing; we provide a comprehensive service that includes personalized customization, in-depth design consultation, and full-scale research and development. We work closely with our clients to understand their unique challenges and engineer solutions that are not only effective but also cost-efficient and optimized for production.

Our capabilities extend across a wide spectrum of materials and product types, making us a one-stop solution for diverse engineering needs. We specialize in working with high-performance engineering plastics such as PEEK, PPS, Nylon, ABS, and PTFE, selecting the ideal material to match the specific functional requirements of each part. Whether you require custom gears, durable pulleys, high-pressure sealing rings, or low-friction bearings, our state-of-the-art plastic moulding service can produce components that excel in their intended environment. This material expertise ensures that every product delivers optimal performance, from wear resistance to chemical stability.

Our reputation for excellence has allowed us to build a strong global presence, serving a growing list of international clients. We proudly export our products to demanding markets in the USA, UK, Canada, Germany, and beyond. This international reach is a testament to our unwavering commitment to quality and customer satisfaction. When you partner with us, you are choosing one of the leading mould companies that combines decades of engineering wisdom with advanced manufacturing technology to bring your vision to life. Let us be your trusted partner in creating the next generation of exceptional products through our expert injection plastic molding services.