We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

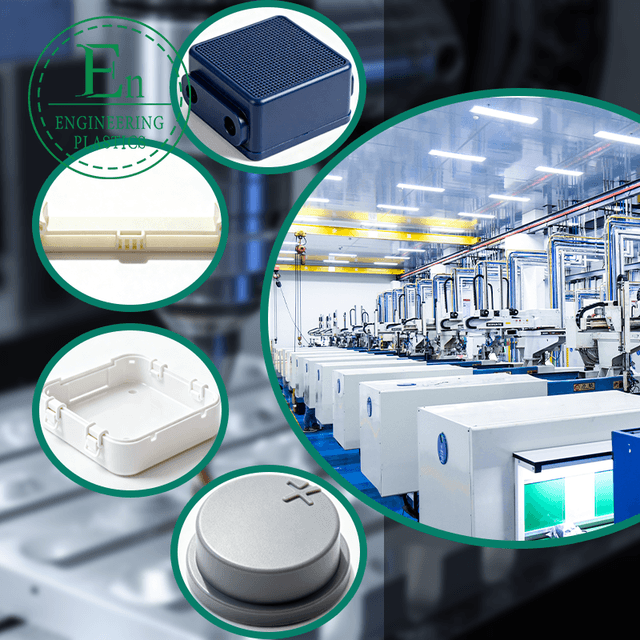

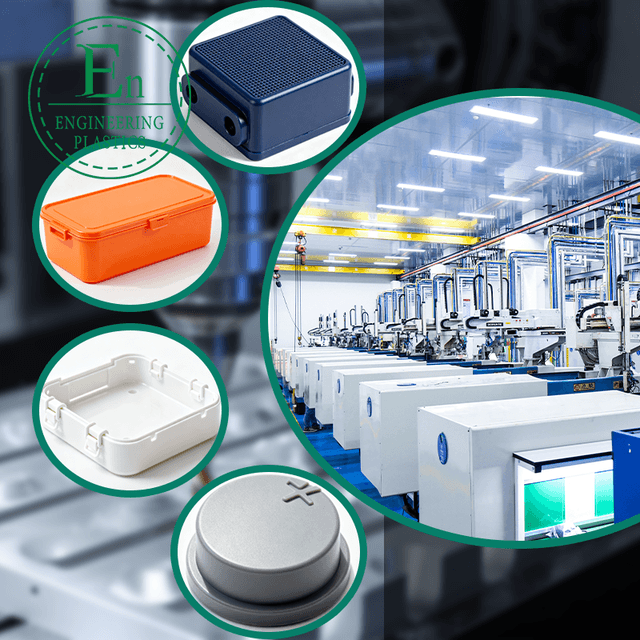

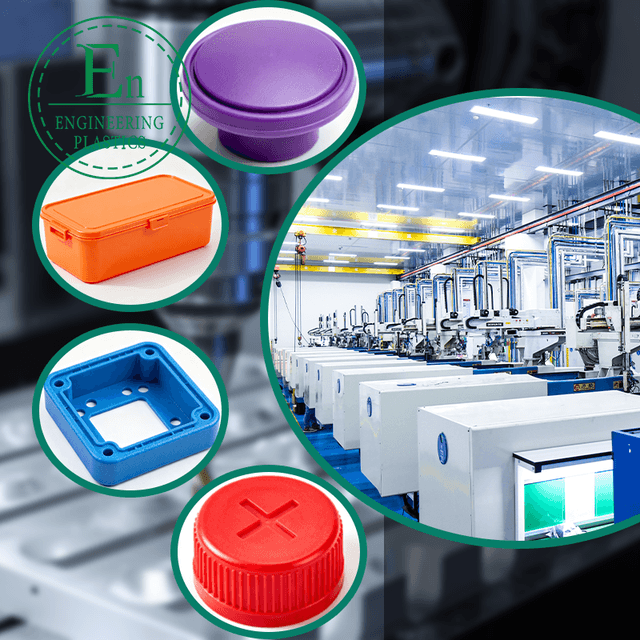

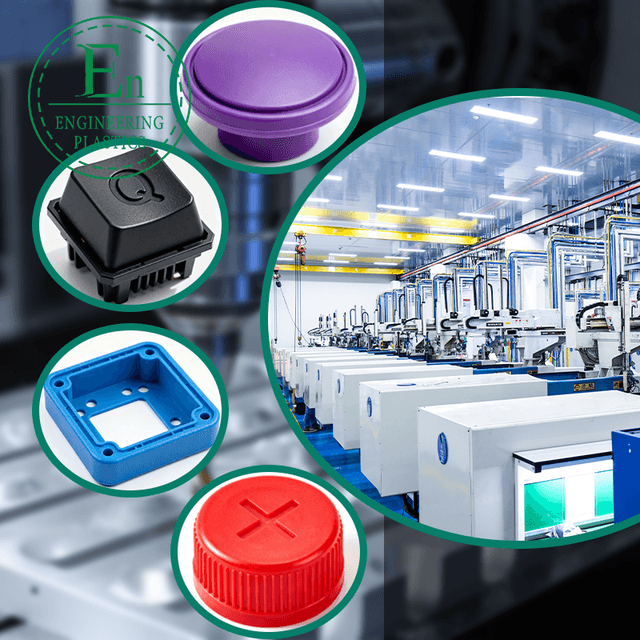

The precision of an *injection mold parting line* can have a significant impact on the quality and functionality of the end product. At Guangdong Engineering Plastics Industries Group Co., Ltd., we place immense importance on perfecting this aspect of our manufacturing process. Our diverse assortment of components is designed to showcase precision, utilizing the extensive expertise of our senior engineers who have 15 to 25 years of industry experience.

The quality of an injection mold parting line is especially critical when working with engineering plastics for industrial applications. For instance, when designing sturdy electronic device casings, such as our **Red Protective Case**, precision in the parting line is crucial to ensure a seamless fit and enhanced durability. This product, made from high-grade engineering plastic, exemplifies our commitment to striking a balance between aesthetic appeal and functional robustness.

Our products, ranging from amber pharmaceutical bottles to dark gray valvular components, are subjected to meticulous design and rigorous testing to ensure their excellence. Despite the complexity involved in molding different colors and materials, our vast experience with injection mold PVC processes and *injection mold supplies* enables us to manufacture components that adhere to global safety and quality standards. Each product in our collection, such as the lime green block connector or the bright orange decorative grille, highlights our innovative approach to design and functionality.

Guangdong Engineering Plastics is not just a manufacturer, but a global leader, exporting meticulously crafted products to clients in the USA, UK, Canada, Germany, and beyond. We specialize in a wide array of engineering plastic products encompassing gears, pulleys, sealing rings, bearings, and more. Our company utilizes advanced materials like PEEK, PPS, Nylon, ABS, and PTFE, ensuring that our offerings meet the stringent demands of both domestic and international markets.

Our commitment to quality and innovation is evident in each product we deliver. With the backing of a highly experienced team, we continue to support and advance technological development across industrial design, offering eco-friendly solutions that blend form, function, and cutting-edge technology. As we adapt to new challenges and expand our operations, we remain true to our mission of providing impeccable engineering solutions globally.