We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

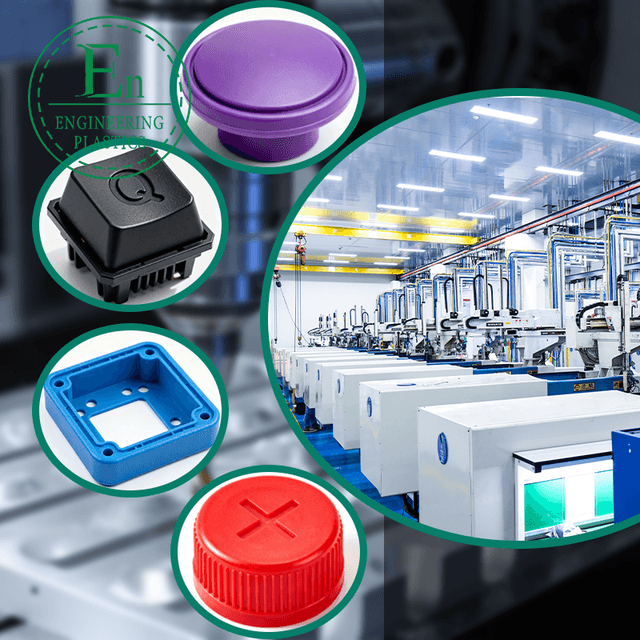

In the world of manufacturing, plastic injection molds making stands as a cornerstone for producing high-quality engineering plastic products. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in this intricate process, leveraging our team's expertise to deliver precision-engineered solutions. With senior engineers boasting 15-25 years of experience, we craft molds that ensure durability and efficiency for diverse industrial applications. Our commitment to innovation allows us to create custom molds tailored to your specific needs, whether for automotive parts, medical devices, or consumer goods. This expertise in plastic injection molds making not only streamlines production but also enhances the overall quality of the final products, making them reliable and cost-effective.

When it comes to specialized applications like mold for PVC, our advanced techniques shine through. PVC, known for its versatility and corrosion resistance, requires molds that can handle its unique properties without compromising on detail or strength. We design and fabricate mold for PVC that facilitate seamless injection processes, resulting in products like protective enclosures and casings that withstand harsh environments. Our state-of-the-art facility employs cutting-edge technology to produce these molds, ensuring tight tolerances and smooth finishes. Clients from the USA, UK, and beyond trust our mold for PVC solutions for their projects in construction, electronics, and more, appreciating the longevity and performance they provide.

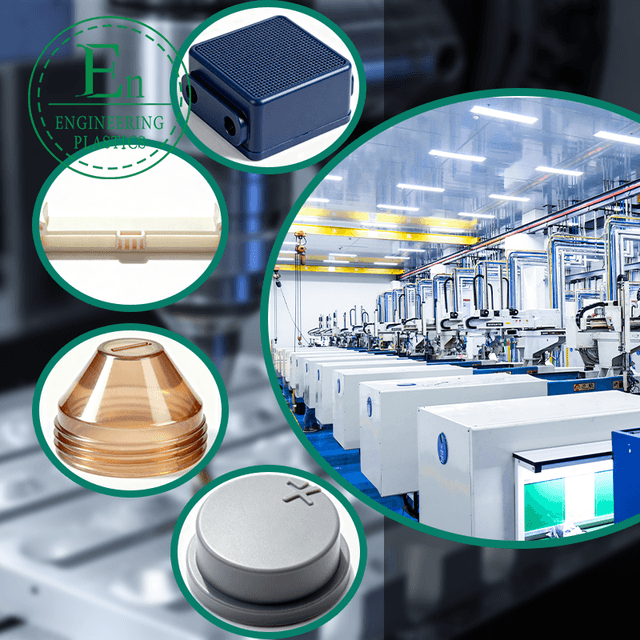

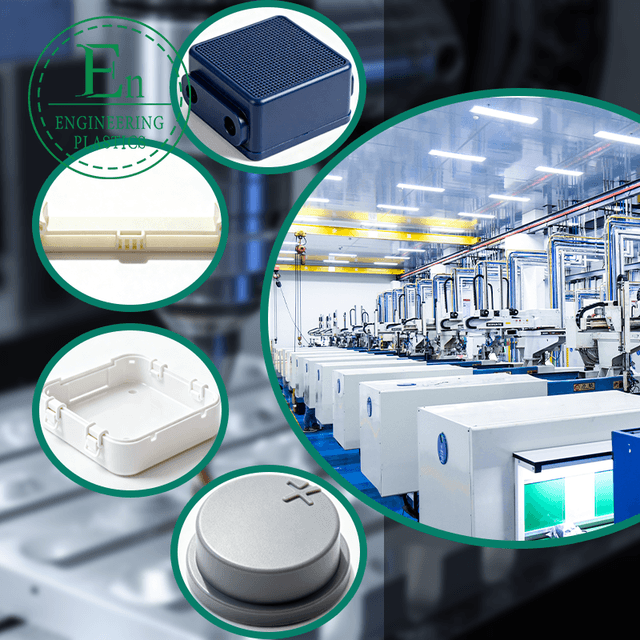

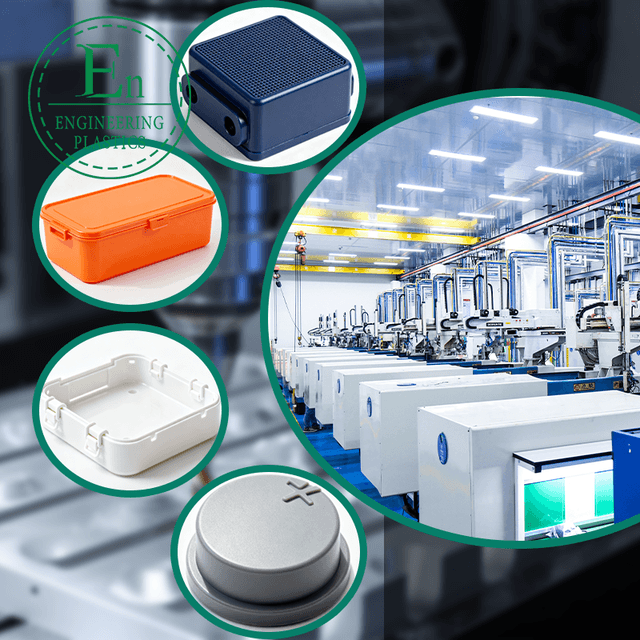

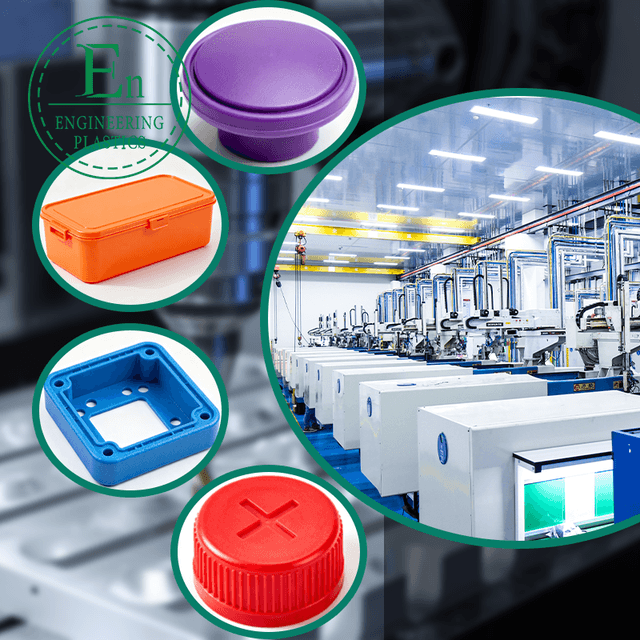

Integrating modern tools such as mould 3D modeling elevates our plastic injection molds making to new heights. By utilizing 3D design software, we create detailed prototypes and simulations before physical production, minimizing errors and accelerating development timelines. This approach is particularly beneficial for complex geometries in mould 3D projects, allowing for rapid iterations and precise adjustments. Our range of engineering plastics, including PEEK, PPS, Nylon, ABS, and PTFE, pairs perfectly with these mould 3D techniques to manufacture items like gears, pulleys, sealing rings, and bearings. The deep blue enclosure, for instance, emerges from our meticulously crafted molds, offering robust protection with an industrial edge for electronic components. Similarly, the vibrant orange casing ensures high visibility for safety equipment, while the pristine white enclosure suits sterile medical settings.

Our sleek capsule container exemplifies the airtight security achieved through superior plastic injection molds making. This product, designed for sensitive item storage, benefits from our comprehensive research and development capabilities, ensuring it meets stringent quality standards. Exporting to markets in Canada, Germany, and further afield, Guangdong Engineering Plastics Industries Group Co., Ltd. has built a global reputation for excellence. We invite you to explore how our mold for PVC and mould 3D innovations can transform your manufacturing processes. With personalized customization at the core, we deliver products that not only meet but exceed expectations, driving your business forward with precision and style. Whether you're seeking durability in harsh conditions or flexibility in design, our engineering plastics are engineered to withstand future industry demands.