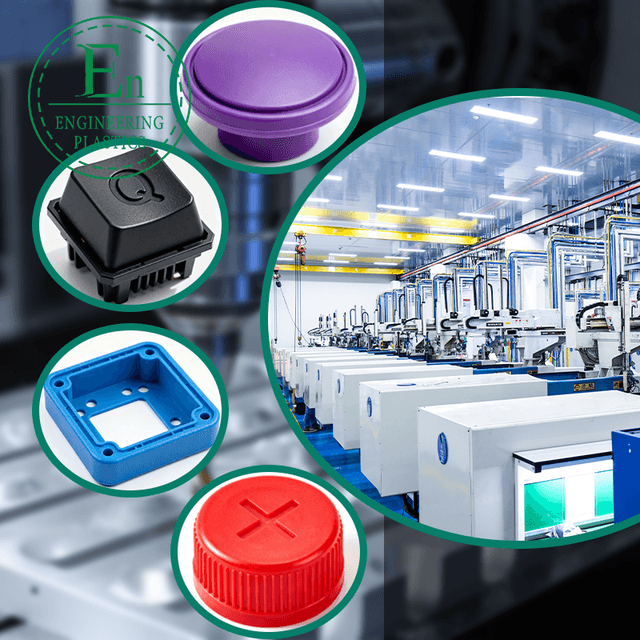

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the competitive world of industrial manufacturing, the manufacture of molds stands as a cornerstone for producing high-quality components that drive innovation across sectors. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in the manufacture of molds that enable the creation of precision-engineered plastic parts, ensuring efficiency and reliability for our global clientele. With a team of senior engineers boasting 15-25 years of expertise, our company delivers personalized customization, from design to final production, using advanced materials like PEEK, PPS, Nylon, ABS, and PTFE. This expertise allows us to cater to diverse needs, exporting our solutions to markets in the USA, UK, Canada, Germany, and beyond, solidifying our reputation for excellence.

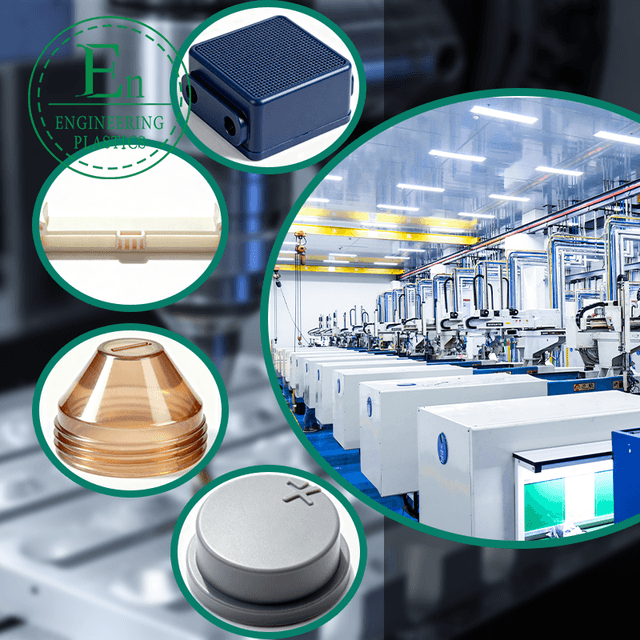

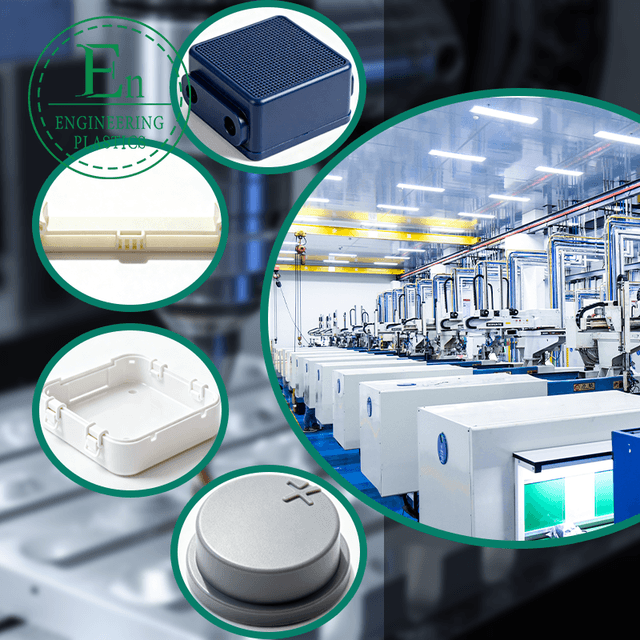

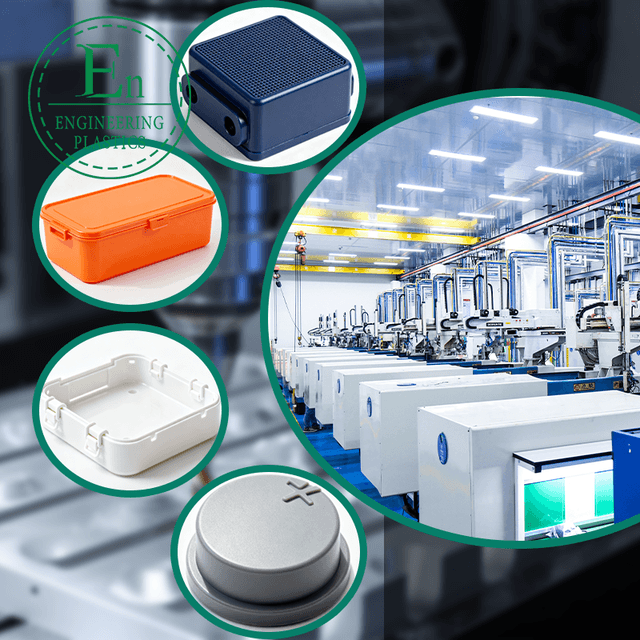

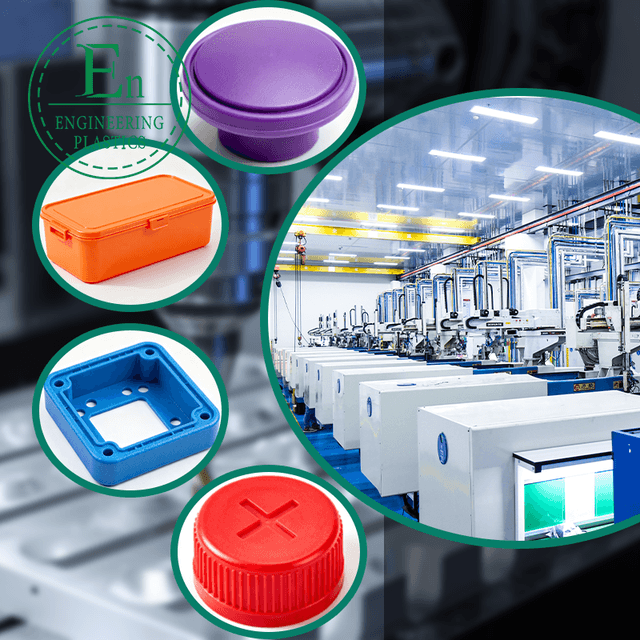

Our rubber injection mold technology represents a pinnacle in flexible and durable production processes, ideal for components that require resilience under varying pressures and temperatures. The rubber injection mold we develop facilitates the seamless integration of rubber elements into assemblies, enhancing the performance of seals, gaskets, and vibration-dampening parts. Complementing this, our plastic moulding dies are crafted with meticulous precision to produce intricate shapes in thermoplastics, supporting applications from automotive to medical devices. For instance, our high-durability casing, engineered through state-of-the-art plastic moulding dies, provides robust protection for electronic components in harsh environments, while our precision molded connector ensures flawless connectivity in complex systems. These molds are not just tools; they embody our commitment to sustainability and efficiency in every cycle of production.

Delving deeper into our offerings, the manufacture of molds at our facility incorporates cutting-edge machinery that minimizes waste and maximizes output quality. Our advanced optical lens, produced via specialized plastic moulding dies, achieves superior light transmission using top-grade transparent polymers, making it indispensable for high-precision instruments in medical and technological fields. Similarly, the premium closure cap benefits from rubber injection mold techniques, offering airtight seals that preserve contents in packaging solutions. We also extend our mold manufacturing prowess to a wide array of engineering plastic products, including gears, pulleys, sealing rings, and bearings, all tailored to withstand extreme conditions. This versatility stems from our comprehensive research and development capabilities, allowing us to adapt molds for specific client requirements, whether for consumer electronics or heavy industrial machinery.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart in the manufacture of molds is our holistic approach, blending traditional craftsmanship with innovative technologies. Our rubber injection mold processes ensure that even the most demanding rubber-based components maintain integrity over time, reducing downtime and maintenance costs for end-users. In parallel, our plastic moulding dies are optimized for high-volume production without compromising on detail, supporting industries that rely on consistent quality. As we continue to expand our global footprint, serving international clients with customized solutions, we remain dedicated to pushing the boundaries of plastic engineering. By investing in the manufacture of molds that align with modern sustainability goals, we help our partners achieve operational excellence and environmental responsibility. This forward-thinking ethos ensures that every mold we produce contributes to the success of innovative projects worldwide.