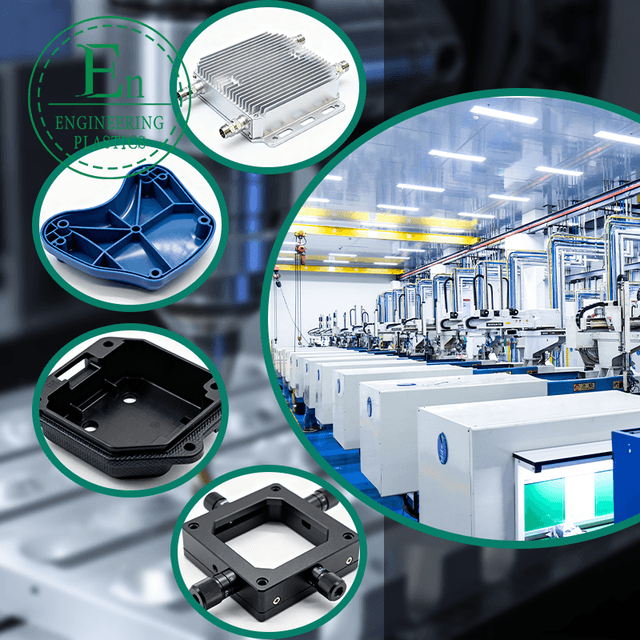

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

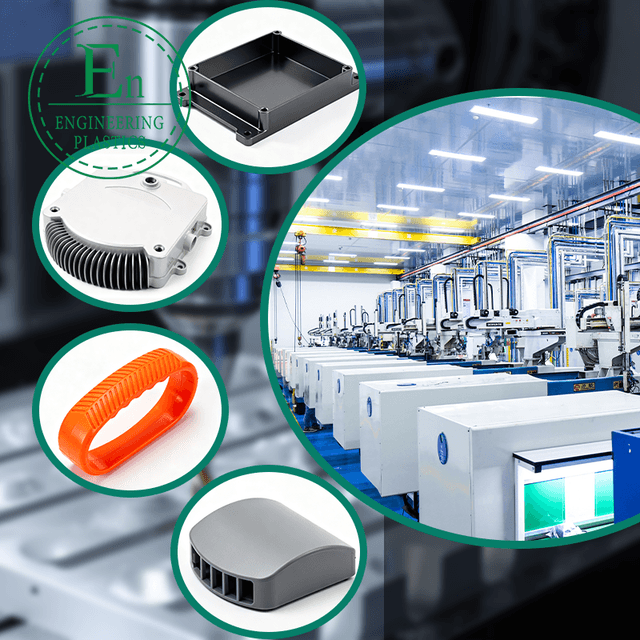

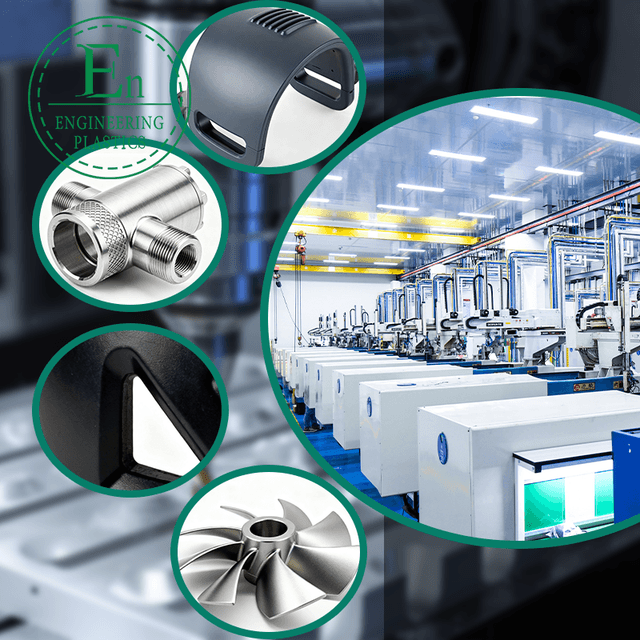

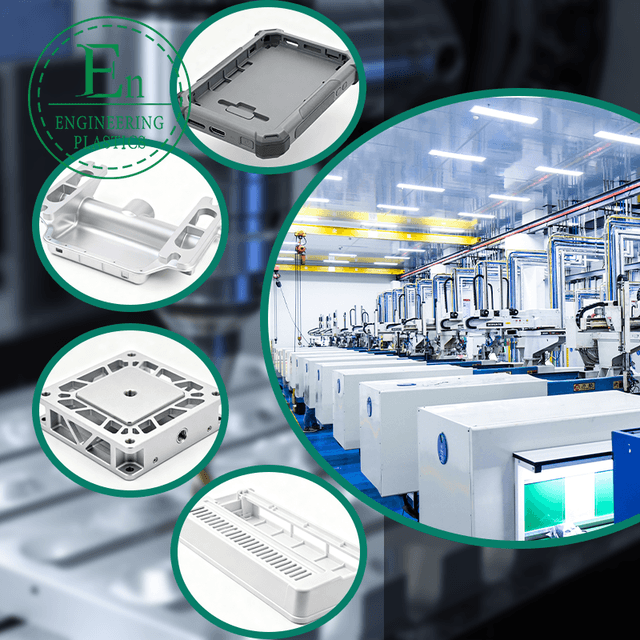

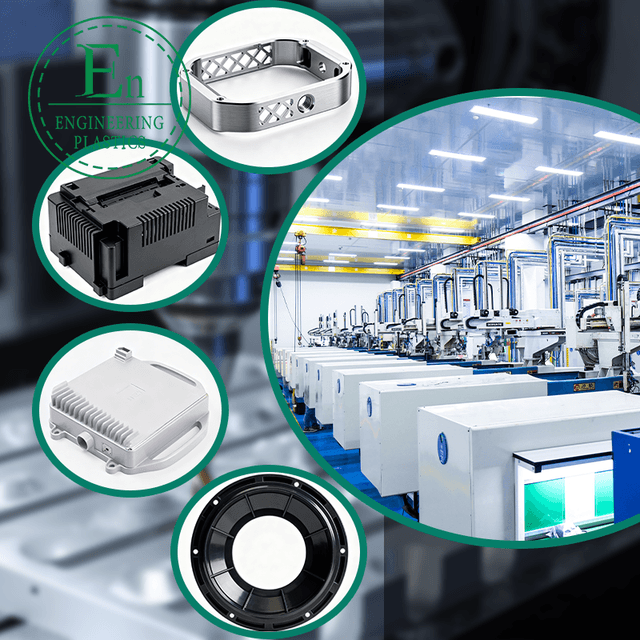

Our expertise includes:

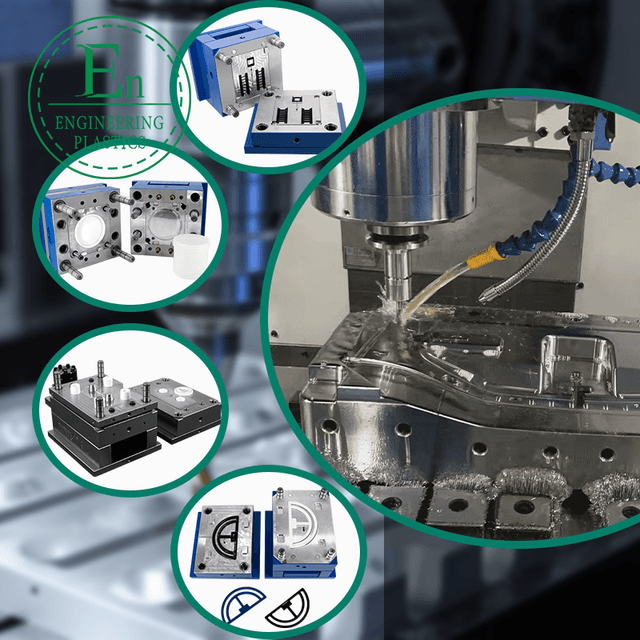

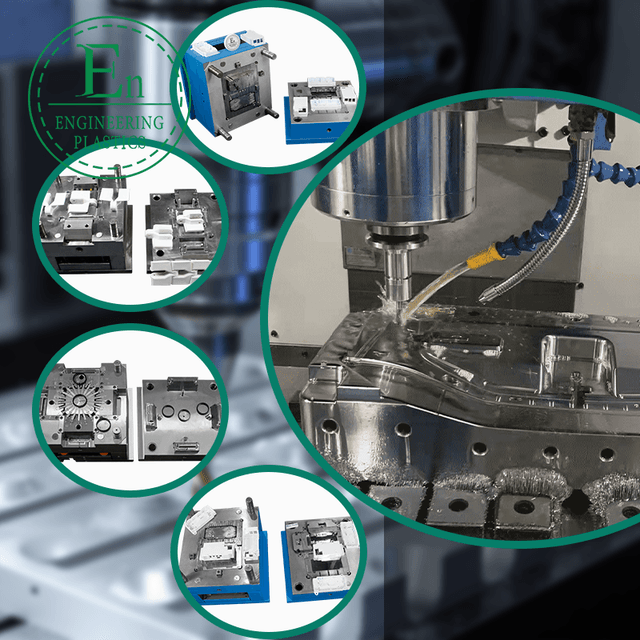

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

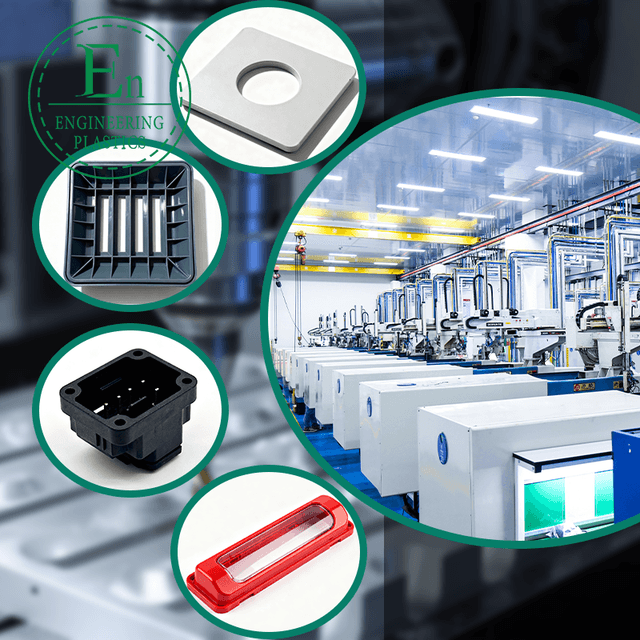

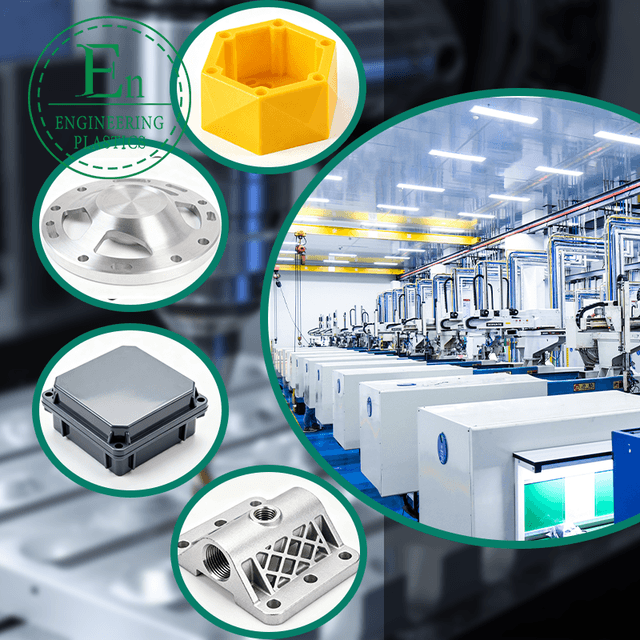

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the competitive world of manufacturing, a high tolerance plastic molding factory plays a pivotal role in delivering precision-engineered components that meet stringent industry standards. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in creating innovative solutions like our advanced Silicone Mould, designed to provide exceptional accuracy and reliability for various applications. This focus on high tolerance ensures that every product we produce adheres to the finest details, making us a trusted partner for businesses seeking top-tier manufacturing services.

As an ISO certified plastics manufacturer, Guangdong Engineering Plastics Industries Group Co., Ltd. upholds the highest quality benchmarks, with our Silicone Mould earning prestigious ISO9001 and SGS certifications. This commitment to excellence means our products are not only durable and resistant to aging and corrosion but also engineered for long-term performance in demanding environments. Our team of senior engineers, boasting 15-25 years of expertise, enables us to offer fully customized services, tailoring the Silicone Mould to specific needs whether for small-scale operations or large industrial projects. High quality plastic parts supplier that we are, we utilize premium materials such as PEEK, PPS, Nylon, ABS, and PTFE to craft components with incredible precision, achieving tolerances up to ±0.01mm. This level of detail allows for the production of intricate gears, pulleys, sealing rings, bearings, and more, ensuring that every piece meets or exceeds customer expectations and contributes to cost savings through reduced maintenance and replacements.

Our reputation as a high tolerance plastic molding factory extends globally, with exports to countries like the USA, UK, Canada, and Germany, reflecting our ability to serve both domestic and international clients effectively. We pride ourselves on comprehensive design, research, and development capabilities, allowing us to innovate and adapt to evolving market demands. As an ISO certified plastics manufacturer, we emphasize personalized customization, helping clients bring their visions to life with products that blend fashion-forward technology and practical efficiency. High quality plastic parts supplier like us understands the importance of versatility, which is why our Silicone Mould is ideal for a wide range of applications, from everyday consumer goods to specialized industrial components. This adaptability not only enhances product longevity but also supports sustainable manufacturing practices by minimizing waste and maximizing resource efficiency.

Beyond our core offerings, Guangdong Engineering Plastics Industries Group Co., Ltd. is dedicated to fostering strong relationships with our clients, providing not just products but solutions that drive success. High tolerance plastic molding factory operations at our facility incorporate state-of-the-art technology and rigorous quality control measures, ensuring that every Silicone Mould we produce is a testament to our unwavering commitment to excellence. As a high quality plastic parts supplier, we continuously invest in our team's expertise and facility upgrades to stay ahead in the industry. Whether you're looking to develop custom molds for automotive, electronics, or medical sectors, our Silicone Mould offers unparalleled precision and reliability, backed by our global track record. In an era where quality and precision define market leaders, partnering with us means accessing a future-proof solution that aligns with your business goals and elevates your operations to new heights.