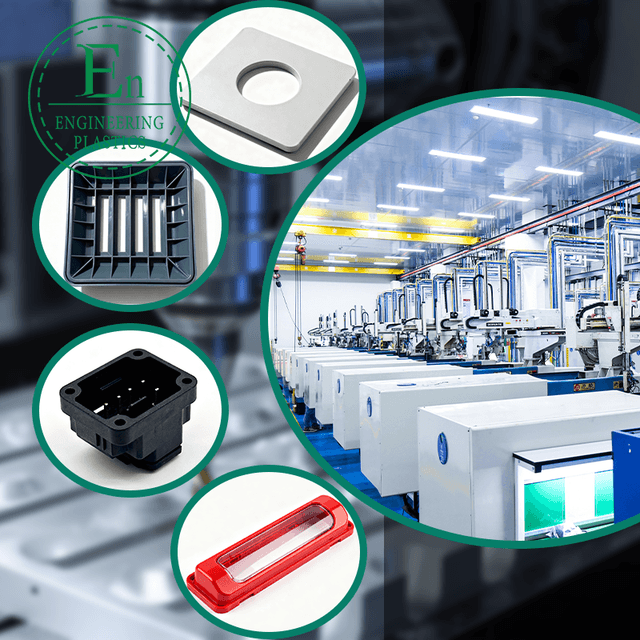

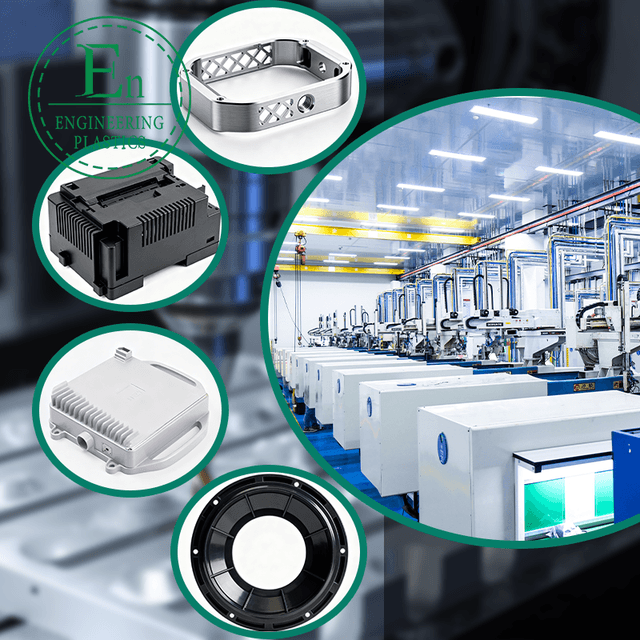

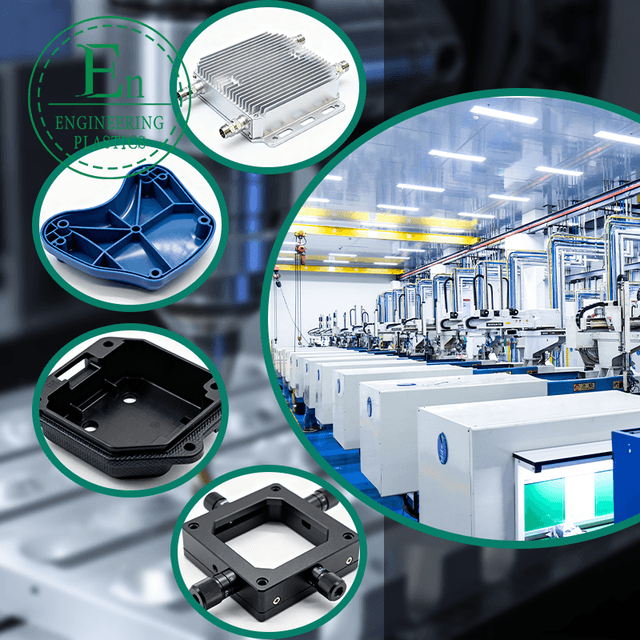

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

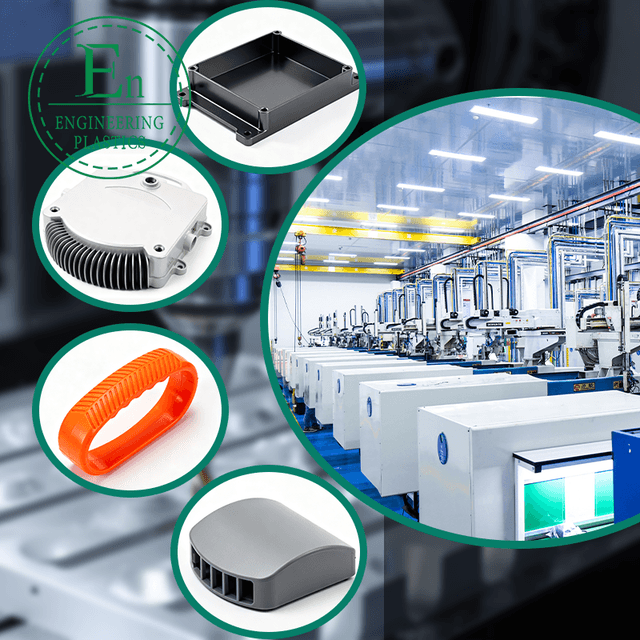

Our expertise includes:

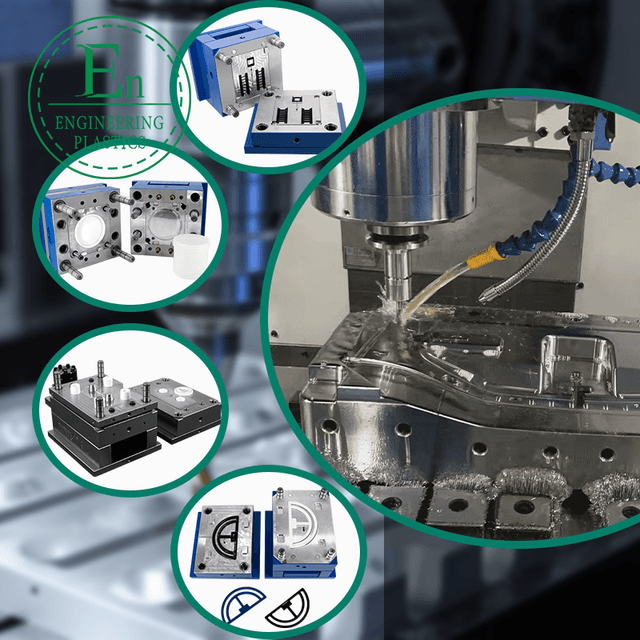

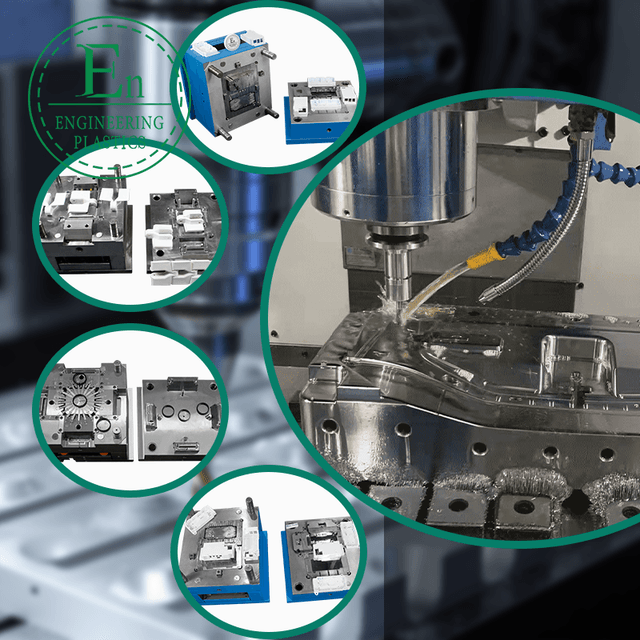

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

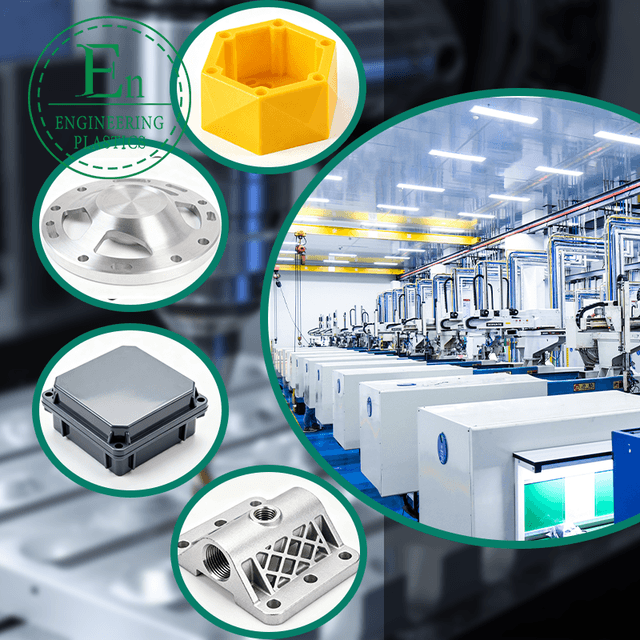

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

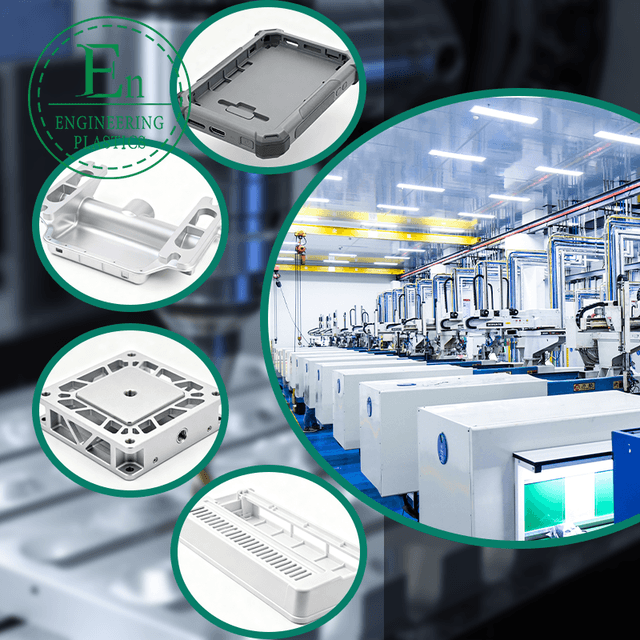

In the realm of molded plastic components, precision and quality are paramount, and this is precisely where the concept of the 'injection mold die' comes into play. At Guangdong Engineering Plastics Industries Group Co., Ltd., we have leveraged over 15-25 years of engineering expertise to bring you an innovative product line that enhances functionality and aesthetic without compromising on durability.

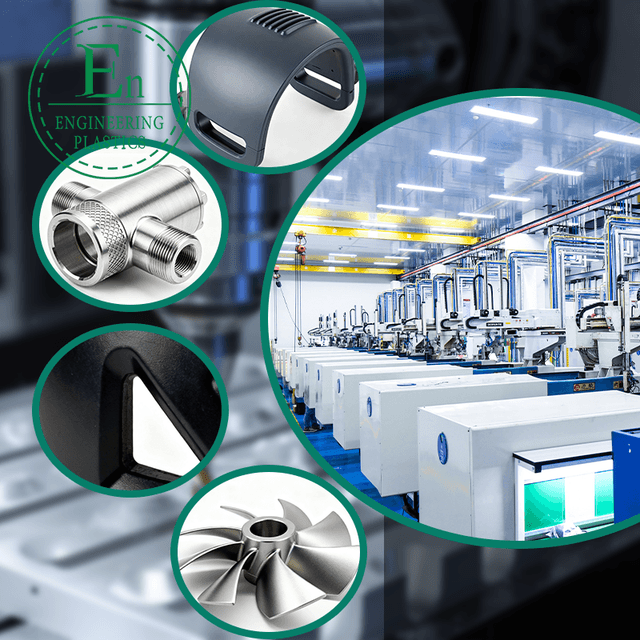

The injection mold die is a crucial aspect of our production process, allowing us to create specific shapes like the cornerstone triangular panel piece. This component is meticulously engineered to serve in various industrial applications, providing both protection for sensitive electronics and ease of installation through thoughtful details like mounting points and connectors. Our products, whether they are gears, pulleys, or enclosures, are results of intricate designs made possible by the customized and comprehensive capabilities of our injection mold die technology.

Incorporating injection mold insert techniques, our products further stand out in the market. These inserts enhance the functionality of the plastic components by providing added strength where necessary, especially in parts like the cylindrical components used for applications requiring rotational mobility. By seamlessly integrating injection mold insert proficiency, we ensure our products maintain superior performance and longevity while remaining lightweight yet incredibly sturdy.

Understanding the importance of design precision, we also focus on the injection mold draft angle—a detail that ensures easy removal of the molded parts from the mold without damage. This attention to the injection mold draft angle is a testament to our dedication to creating components that not only fit perfectly within any electronic or mechanical system but also streamline the assembly process for our clients.

Our dedication to quality extends beyond individual components to encompass a holistic approach to manufacturing. Employing high-grade engineering plastics like PEEK, PPS, Nylon, and more, we prioritize impact resistance and wear endurance in our products. The matte black finish provides a sleek, professional appearance that complements any modern design ethos without distraction.

Serving a global client base across countries such as the USA, UK, Canada, Germany, and more, Guangdong Engineering Plastics Industries Group Co., Ltd. remains a trusted name in the field of engineering plastics. As we continue to innovate and refine our processes, the injection mold die and related technologies remain at the heart of our manufacturing excellence, ensuring our components stand at the pinnacle of durability and design in the market.