We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

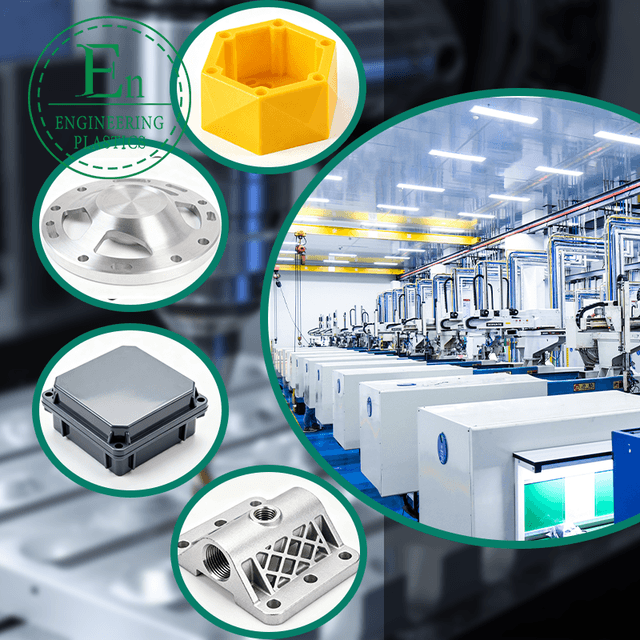

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

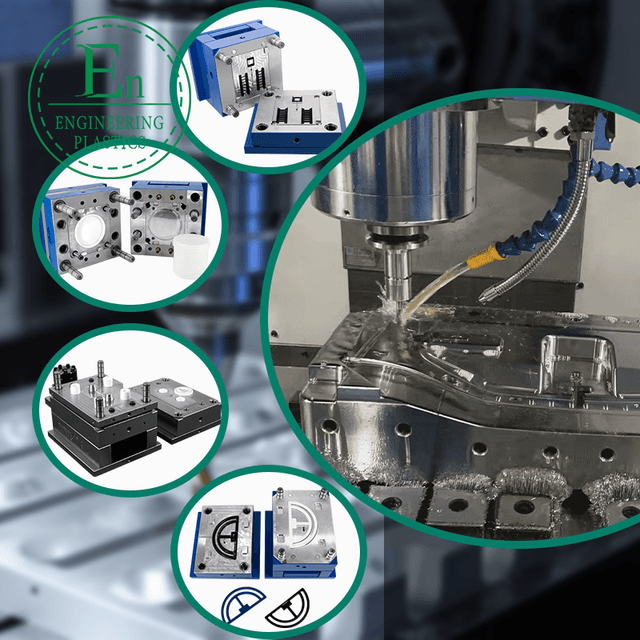

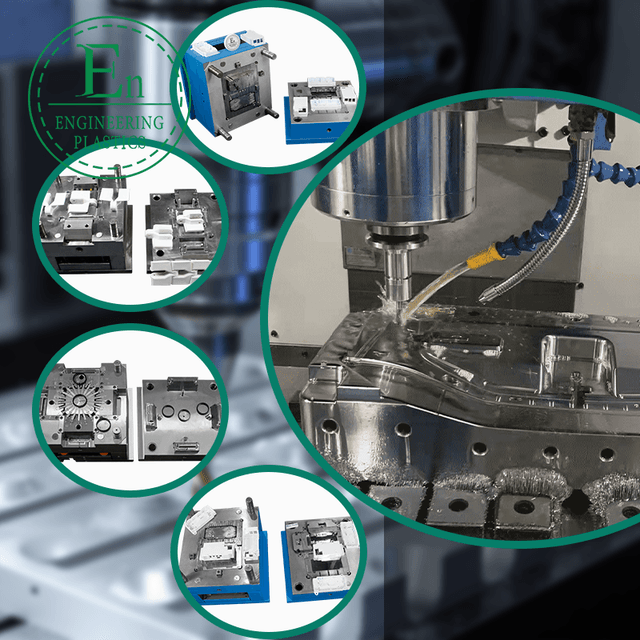

In the world of advanced manufacturing, a precise mould stands as the cornerstone of quality and efficiency, enabling the creation of intricate components with unmatched accuracy. At Guangdong Engineering Plastics Industries Group Co., Ltd., we harness our team's expertise—comprising senior engineers with 15-25 years of experience—to deliver superior precise mould solutions tailored to your needs. Our commitment to innovation ensures that every mould we produce supports comprehensive design, research, and development, making us a trusted partner for industries worldwide.

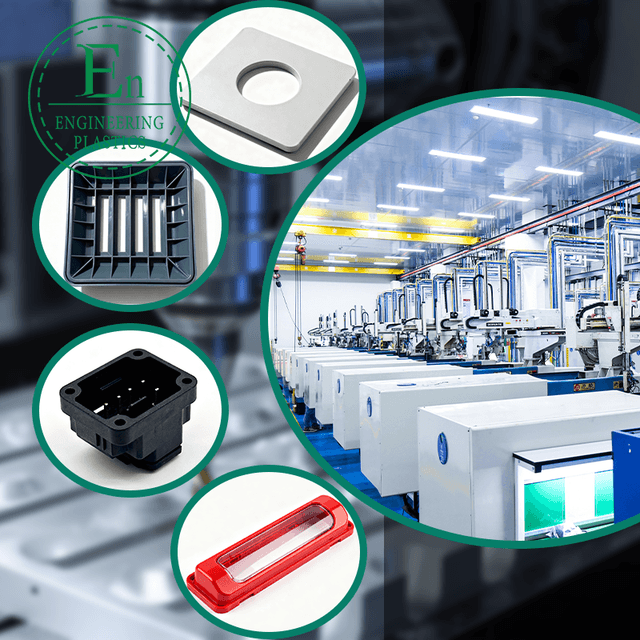

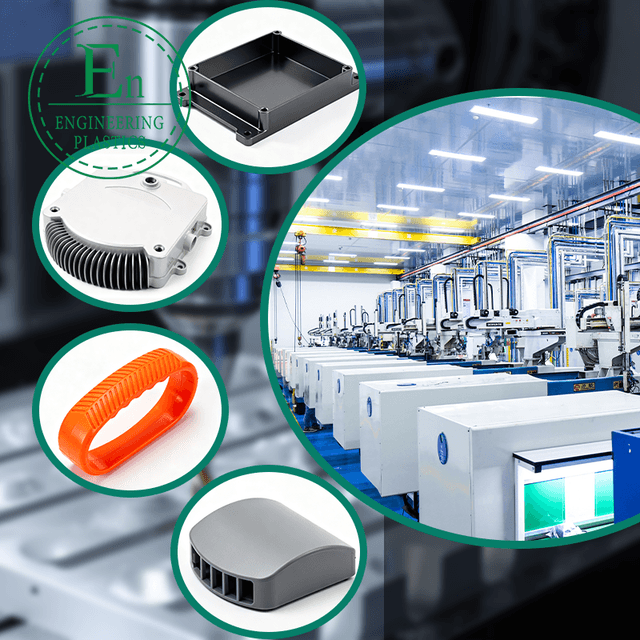

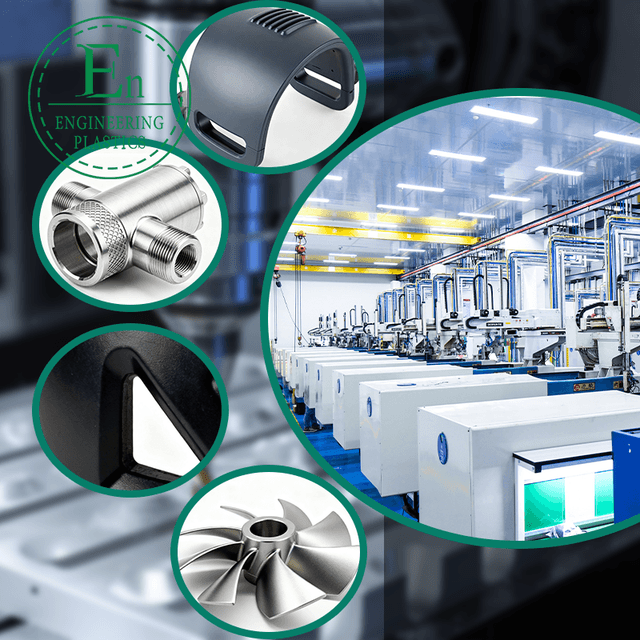

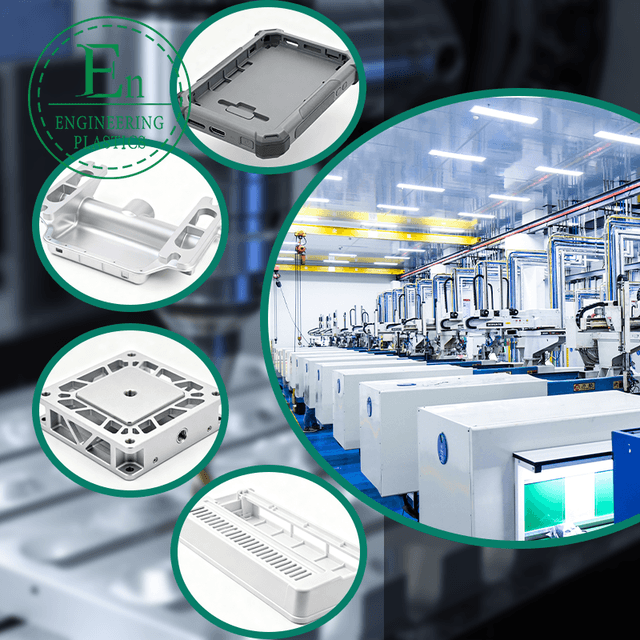

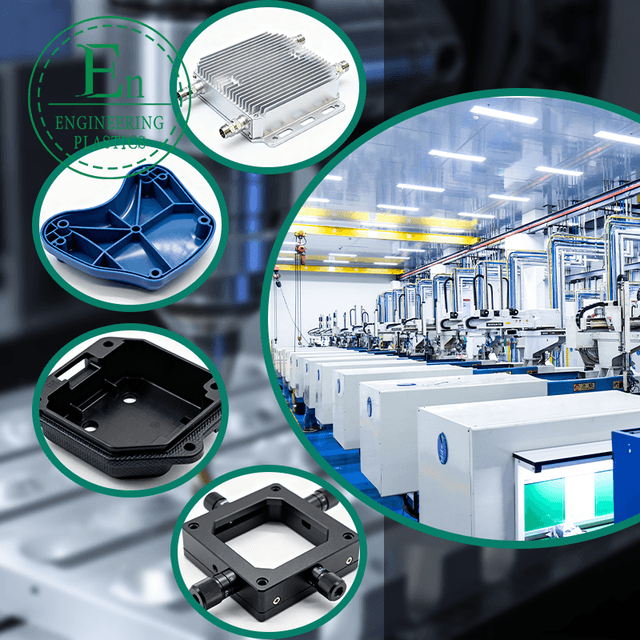

Delving deeper, our precise mould technology excels in producing high-performance engineering plastic components, from elegant metallic frames to robust black housings and versatile white casings. These moulds are crafted using state-of-the-art techniques in our high-tech facility, where automation and precision engineering guarantee consistency and speed. Whether you're developing gears, pulleys, sealing rings, or bearings from materials like PEEK, PPS, Nylon, ABS, or PTFE, our precise moulds minimize defects and maximize output, setting a new benchmark for reliability in demanding applications.

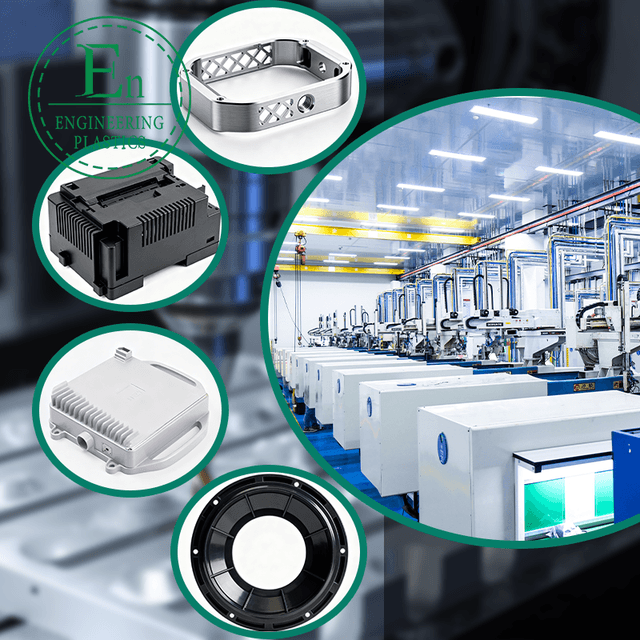

One of our flagship offerings is the injection molding mould, designed specifically for high-volume production with exceptional detail retention. This injection molding mould integrates advanced cooling systems and durable steel constructions to handle the rigors of repeated cycles, ensuring longevity and cost-effectiveness. Ideal for creating components like the circular acoustic parts that deliver unmatched sound quality with minimal distortion, our injection molding mould supports a wide array of sectors, including automotive, electronics, and consumer goods. Clients from the USA, UK, Canada, Germany, and beyond rely on us for these moulds, appreciating our ability to customize designs that align perfectly with their specifications.

Complementing our core capabilities, the ABS plastic injection mold represents a pinnacle of material-specific innovation. Engineered for ABS resins, this ABS plastic injection mold excels in forming complex geometries, such as the sleek black components that prioritize efficiency and sustainability. With superior impact resistance and thermal stability, our ABS plastic injection mold facilitates the production of protective casings and structural elements that withstand harsh environments. Our global reputation stems from delivering these moulds with precision tolerances as fine as 0.01mm, reducing waste and enhancing the overall performance of your end products.

Furthermore, our precise mould portfolio extends to personalized solutions that embody the essence of modern manufacturing. By leveraging our extensive experience, we offer end-to-end services—from initial prototyping to full-scale production—ensuring seamless integration into your supply chain. The intricate patterns and optimized configurations in our moulds not only boost aesthetic appeal but also contribute to functional strength, as seen in audio applications where sound wave management is critical. Exporting to international markets, we maintain stringent quality standards that comply with global regulations, fostering long-term partnerships built on trust and excellence.

In summary, choosing Guangdong Engineering Plastics Industries Group Co., Ltd. for your precise mould needs means investing in innovation, durability, and expertise. Our injection molding mould and ABS plastic injection mold are more than tools; they are gateways to superior engineering plastics components that drive efficiency and competitiveness. With a proven track record serving diverse industries, we invite you to explore how our precise mould solutions can elevate your projects to new heights of precision and performance.