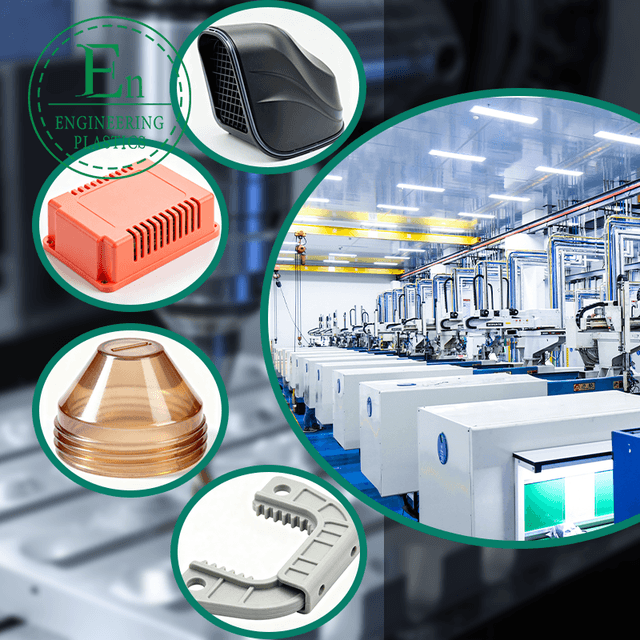

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, a high-quality mold for plastic casting stands as the cornerstone of efficient production. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting these essential tools that enable the creation of durable and intricate plastic components. With our advanced facilities equipped with state-of-the-art injection molding machines, we ensure that every mold for plastic casting delivers unparalleled accuracy and reliability. Our commitment to innovation allows us to meet the diverse needs of industries ranging from automotive to electronics, producing parts that are not only strong but also sustainably sourced.

When it comes to specialized applications, our plastic rubber mold solutions offer exceptional versatility. Designed for handling materials like Nylon, ABS, and PTFE, these molds facilitate the seamless integration of rubber-like properties into plastic products, enhancing flexibility and resilience. Our senior engineers, boasting 15-25 years of expertise, meticulously design each plastic rubber mold to withstand high-pressure environments while maintaining precise tolerances. This expertise has enabled us to serve global clients in the USA, UK, Canada, and Germany, exporting products that uphold our reputation for quality and customization. Whether you're developing sealing rings or bearings, our plastic rubber mold technology ensures optimal performance and longevity in demanding conditions.

For high-volume production runs, the injection moulding die from Guangdong Engineering Plastics Industries Group Co., Ltd. represents the pinnacle of engineering excellence. These dies are engineered for maximum efficiency, incorporating cutting-edge features that minimize cycle times and reduce material waste. Utilizing materials such as PEEK and PPS, our injection moulding die produces components like gears and pulleys with intricate details and vibrant finishes. Our comprehensive research and development capabilities allow for personalized customization, tailoring each die to specific project requirements. This approach not only boosts productivity but also aligns with our sustainability goals, creating eco-friendly manufacturing processes that benefit both our international clientele and the environment.

Beyond standard offerings, our molds integrate seamlessly into modern production lines, supporting a wide array of applications. Imagine robust brackets for heavy-duty automotive use or precise electronic housings—all made possible through our innovative mold for plastic casting designs. We pride ourselves on a holistic service model that includes design consultation, prototyping, and full-scale manufacturing, ensuring that every project exceeds expectations. As we continue to expand our global footprint, Guangdong Engineering Plastics Industries Group Co., Ltd. remains dedicated to pushing the boundaries of plastics technology. Our injection moulding die and plastic rubber mold solutions are more than tools; they are gateways to superior performance and innovation in engineering plastics. With a focus on durability, precision, and client satisfaction, we invite you to experience the difference that expert craftsmanship can make in your next project.