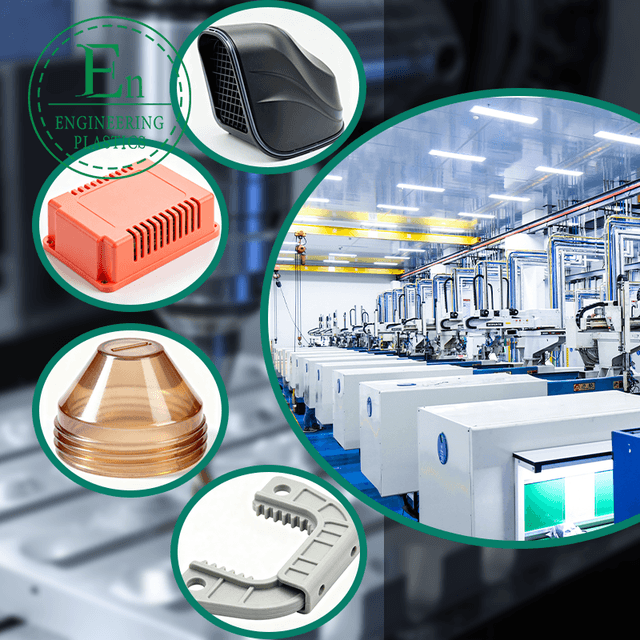

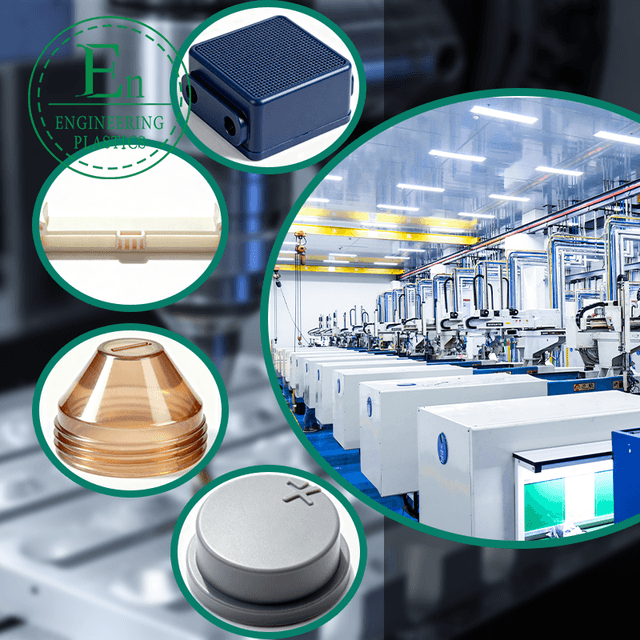

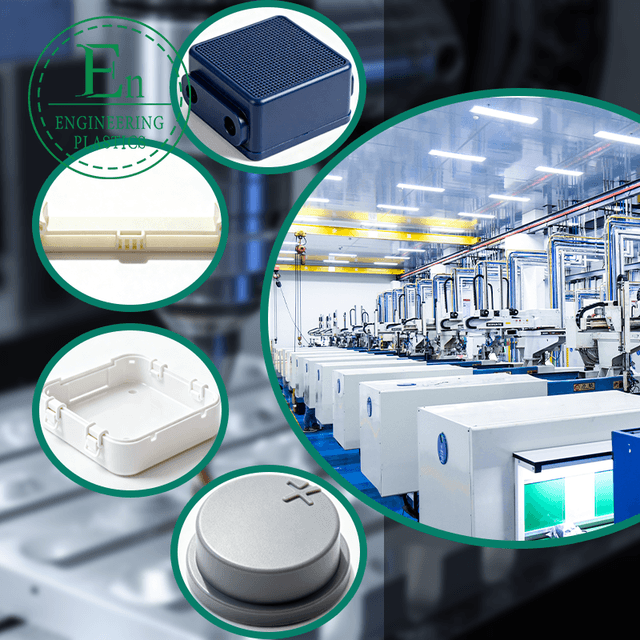

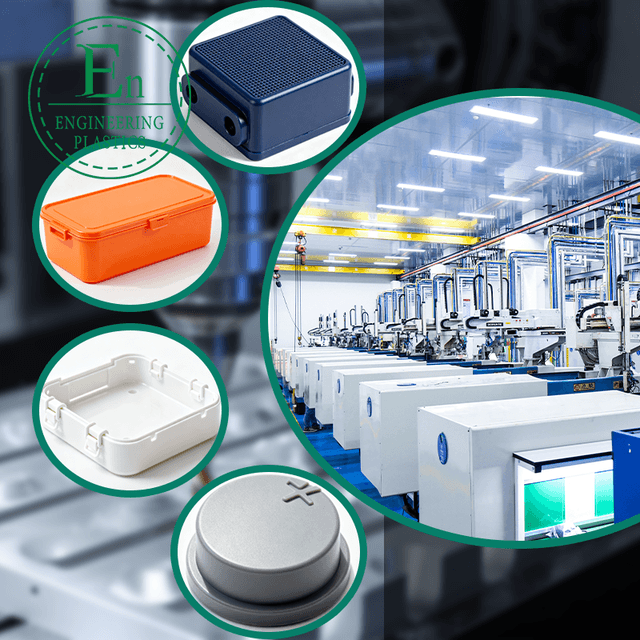

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of advanced manufacturing, peek injection molding stands out as a revolutionary technique for producing high-performance engineering plastic components. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in peek injection molding to create precision parts that meet the stringent demands of modern industries. Our state-of-the-art processes ensure that every component, from gears to seals, delivers unparalleled reliability and efficiency. By leveraging peek injection molding, we transform high-grade PEEK materials into durable solutions that withstand extreme conditions, making them essential for sectors like aerospace, automotive, and medical devices.

Our expertise extends beyond peek injection molding to include complementary technologies such as die casting mould fabrication, which allows us to produce robust metal components alongside our plastic offerings. The die casting mould process is meticulously engineered in our facility, ensuring tight tolerances and superior surface finishes for applications requiring strength and precision. Whether you're developing machinery housings or intricate fittings, our die casting mould capabilities provide the foundational support for hybrid assemblies that combine the best of metal and plastic engineering. This integrated approach not only enhances product performance but also streamlines production for our global clients, from the USA to Germany.

Complementing our core services, we excel in plastic die mold design and manufacturing, offering versatile solutions for a wide array of plastic materials including Nylon, ABS, and PTFE. Plastic die mold technology is crucial for creating custom seals, bearings, and pulleys that operate seamlessly in challenging environments. Our senior engineers, with 15-25 years of experience, collaborate closely with clients to develop tailored plastic die mold solutions that optimize material usage and reduce manufacturing costs. This personalized service ensures that every project aligns with specific performance goals, whether it's minimizing friction in gears or enhancing the longevity of sealing rings.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our commitment to innovation and quality across all processes. From initial design through to final production, our peek injection molding, die casting mould, and plastic die mold services are backed by cutting-edge technology and rigorous quality controls. We export to prestigious markets in the UK, Canada, and beyond, building lasting partnerships through our dedication to customization and excellence. Our diverse product line, encompassing everything from high-efficiency gears to resilient seals, is crafted to elevate your projects to new heights of precision and durability.

As we continue to push the boundaries of engineering plastics, Guangdong Engineering Plastics Industries Group Co., Ltd. invites you to explore how our peek injection molding expertise can transform your ideas into reality. With a focus on sustainability and performance, our components are designed not just to meet but exceed industry standards. Whether you're scaling production or prototyping innovative designs, our comprehensive capabilities in die casting mould and plastic die mold ensure a seamless integration of advanced manufacturing techniques. Join countless satisfied clients worldwide who trust us for reliable, high-quality solutions that drive success in competitive landscapes.