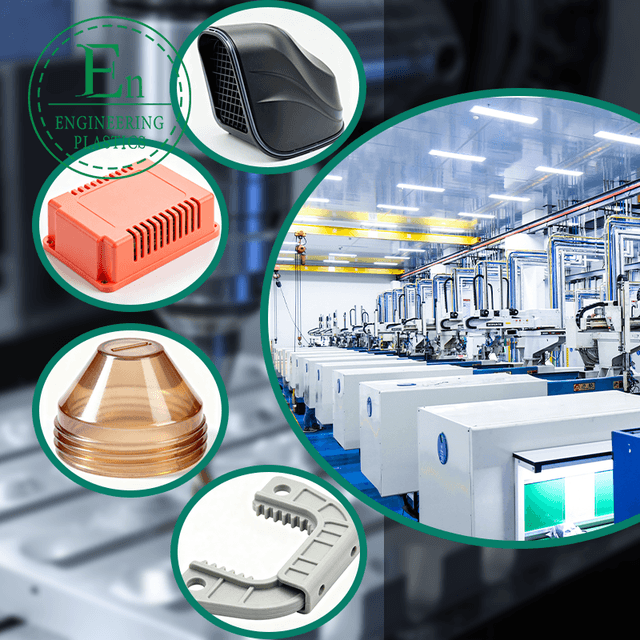

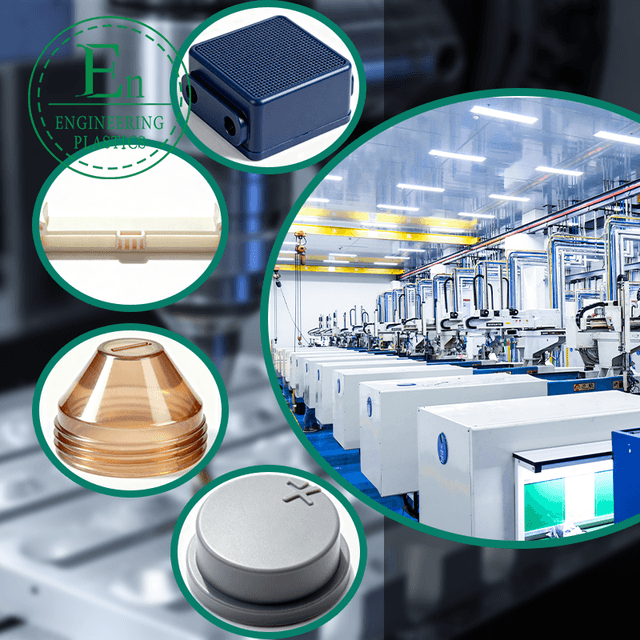

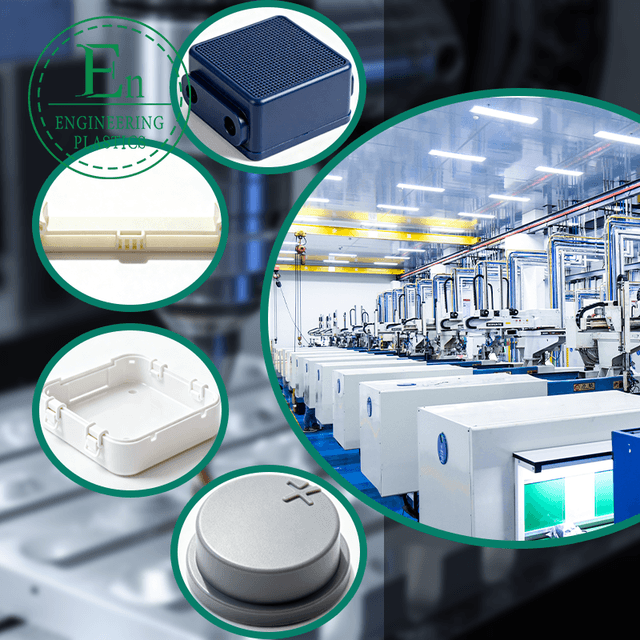

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the competitive world of precision manufacturing, the mold bottle stands out as a revolutionary solution for efficient production processes. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting high-quality mold bottle designs that integrate seamlessly with advanced manufacturing techniques. Our mold bottle products are engineered to deliver unparalleled accuracy and reliability, making them indispensable for industries requiring robust plastic components.

Our expertise in the manufacture of plastic molds ensures that every mold bottle is produced with meticulous attention to detail. With a team of senior engineers boasting 15-25 years of experience, we offer personalized customization options that align perfectly with your specific needs. Whether you're developing intricate gears, durable pulleys, or flexible sealing rings, our mold bottle technology leverages materials like PEEK, PPS, Nylon, ABS, and PTFE to guarantee superior performance. This approach not only enhances the longevity of your products but also optimizes operational efficiency in diverse applications, from complex machinery to everyday mechanical systems.

Delving deeper into silicone injection molding, our mold bottle innovations shine through their ability to handle high-precision molding with exceptional flexibility and strength. This process allows for the creation of custom-shaped plastic parts that prevent leaks and ensure stability, crucial for sectors like automotive, aerospace, and electronics. Our state-of-the-art facilities employ cutting-edge technology and rigorous quality control measures, resulting in mold bottles that meet international standards. Clients across the USA, UK, Canada, Germany, and beyond trust our global reputation for delivering engineering plastics that boost functionality and reduce downtime.

What sets our mold bottle apart is the comprehensive design, research, and development capabilities we bring to the table. From initial concept to final production, we collaborate closely with you to refine every aspect of the manufacture of plastic molds, ensuring the end result is a product that exceeds expectations. Silicone injection molding further enhances this by providing vibrant, robust seals and washers that maintain integrity under extreme conditions. As we continue to serve both domestic and international markets, Guangdong Engineering Plastics Industries Group Co., Ltd. remains committed to innovation, offering solutions that drive your success in modern manufacturing.

Exploring the broader impact, our mold bottle solutions contribute to sustainable practices by minimizing material waste through precise silicone injection molding techniques. This not only lowers costs but also supports eco-friendly initiatives without compromising on quality. Our diverse selection of engineering plastics, including bearings and more, is tailored to enhance the performance of your assemblies. With a proven track record of excellence, we invite you to experience how our mold bottle expertise can transform your production line, delivering efficiency, durability, and precision every time.