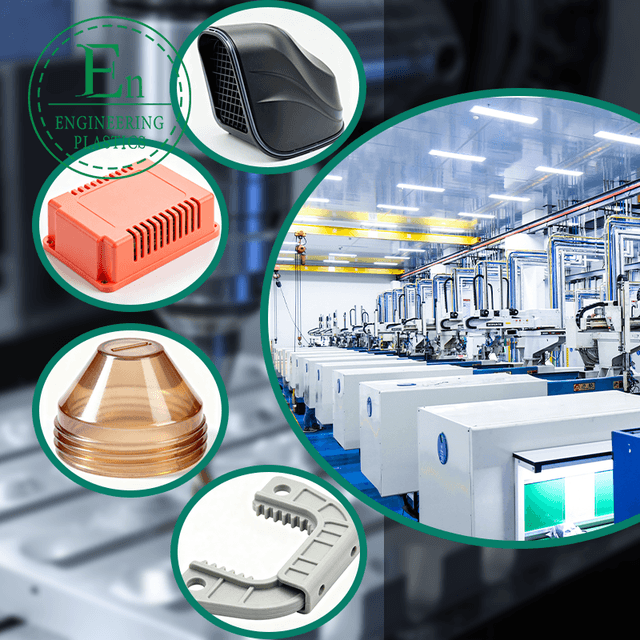

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

As a leading die casting mold manufacturer, Guangdong Engineering Plastics Industries Group Co., Ltd. is at the forefront of delivering precision-engineered solutions for industries worldwide. With a team of senior engineers boasting 15-25 years of expertise, we specialize in creating high-quality molds that ensure efficiency and reliability in production processes. Our state-of-the-art facility integrates advanced automation and sustainable practices to produce molds tailored for demanding applications, from automotive components to electronic housings. This commitment to innovation allows us to offer personalized customization, meeting the unique needs of our clients with unmatched precision and durability.

Expanding our expertise, we excel in medical mold plastic injection, where precision is paramount for healthcare applications. Our medical mold plastic injection processes utilize top-grade materials like PEEK, PPS, and Nylon to fabricate components such as seals, gears, and housing covers that withstand rigorous sterilization and operational stresses. These molds are designed to produce vibrant, diverse plastic parts that adhere to stringent regulatory standards, ensuring safety and performance in medical devices. By leveraging our comprehensive design, research, and development capabilities, we provide solutions that enhance functionality and reduce manufacturing downtime, serving clients who require the highest levels of quality in life-critical environments.

In addition to our core strengths, our plastic mold for plastic casting services cater to a broad spectrum of industrial needs, including consumer goods and electronics. Our plastic mold for plastic casting techniques enable the creation of versatile components like pulleys, bearings, and sealing rings using materials such as ABS and PTFE. These molds are engineered for high resistance and adaptability, available in various colors and shapes to fit specific project requirements. With exports to the USA, UK, Canada, Germany, and beyond, we have built a strong global reputation for delivering robust, reliable products that exceed industry benchmarks. Our focus on sustainability and efficiency ensures that every plastic mold for plastic casting project aligns with modern manufacturing goals, providing cost-effective and eco-friendly outcomes.

At Guangdong Engineering Plastics Industries Group Co., Ltd., our role as a premier die casting mold manufacturer extends beyond production to foster long-term partnerships with domestic and international clients. Whether it's optimizing medical mold plastic injection for innovative healthcare solutions or refining plastic mold for plastic casting for everyday applications, our engineering plastics are designed for versatility and excellence. We invite you to explore how our expertise can elevate your next project, combining cutting-edge technology with proven reliability to drive success in your operations.