We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

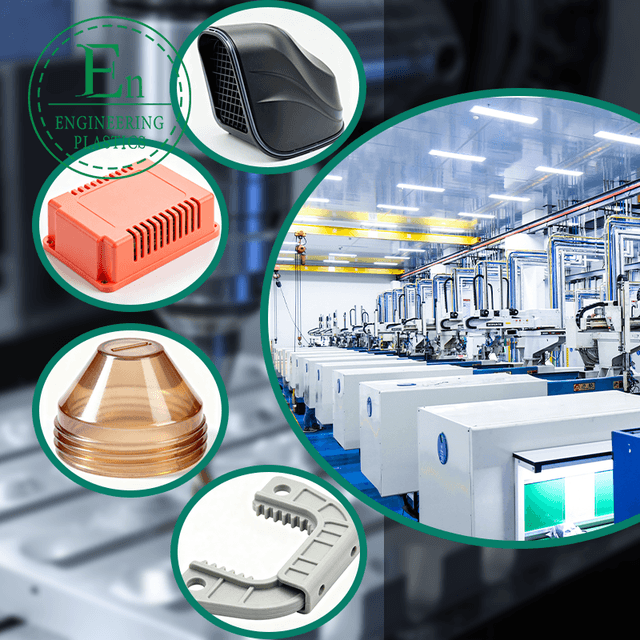

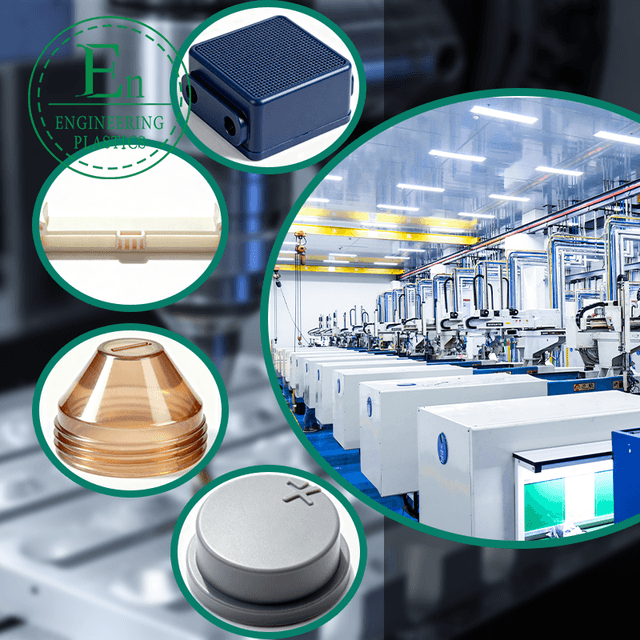

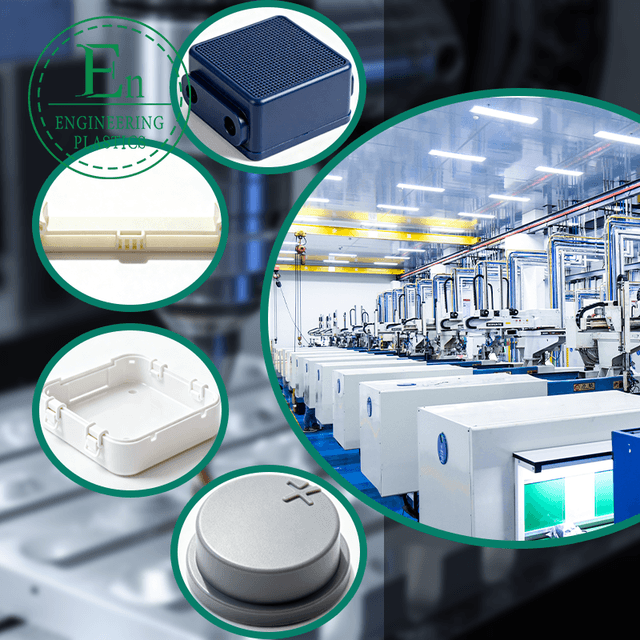

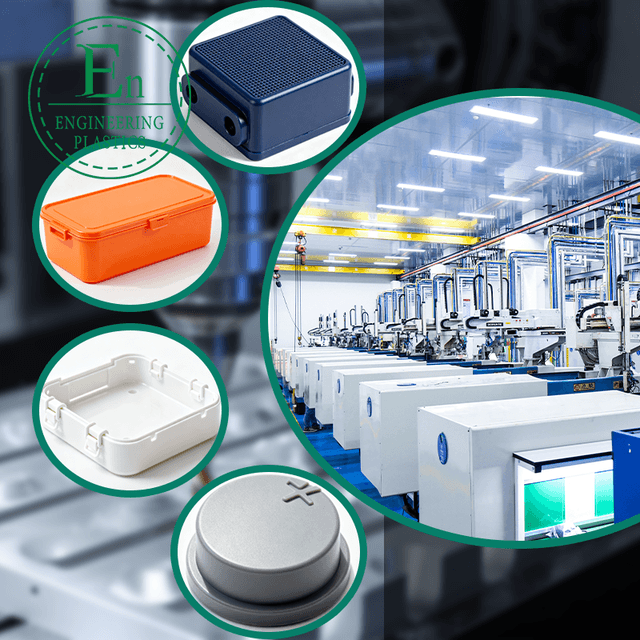

In the competitive world of manufacturing, mold making factories play a pivotal role in transforming innovative designs into tangible products. At Guangdong Engineering Plastics Industries Group Co., Ltd., our state-of-the-art mold making factories are equipped to handle the most demanding projects, ensuring precision and efficiency from concept to completion. With a team of senior engineers boasting 15-25 years of expertise, we specialize in creating custom molds that cater to industries worldwide. Our facilities integrate advanced technology and sustainable practices, producing high-quality engineering plastic components that meet rigorous international standards. Whether you're in electronics or automotive, our mold making factories deliver solutions that drive innovation and reliability.

One of our key specialties within these mold making factories is electronic injection molding, a process that allows for the seamless production of intricate components with exceptional accuracy. Electronic injection molding is ideal for crafting durable enclosures and connectors that protect sensitive circuitry in devices ranging from consumer gadgets to industrial machinery. For instance, our durable blue enclosure, designed through precise electronic injection molding, provides robust protection against impacts and environmental stressors, making it perfect for both indoor and outdoor applications. This technique ensures high-strength plastic designs that resist wear, enhancing the longevity of electronic products. Similarly, our precision molded white connector exemplifies the finesse of electronic injection molding, offering secure fits and superior resistance to strenuous conditions. By leveraging electronic injection in our mold making factories, we enable clients to achieve seamless integration in complex systems, reducing assembly times and minimizing defects. Our export success to markets like the USA, UK, and Germany underscores the reliability of these processes, as we consistently deliver components that exceed expectations.

Complementing our expertise, injection molding silicone opens up versatile applications in our mold making factories, particularly for components requiring flexibility and thermal stability. Injection molding silicone is renowned for producing parts that withstand extreme temperatures and chemicals, making it invaluable for sealing and gripping solutions. Take our advanced grey gripping tool, crafted via injection molding silicone, which features anti-slip properties and ergonomic design for enhanced safety in manual and automated operations. This method allows for the creation of translucent cone-shaped components that ensure optimal light transmission in optical applications, minimizing distortion for precise alignments. In our facilities, injection molding silicone is combined with materials like PEEK, PPS, Nylon, ABS, and PTFE to manufacture a wide array of products, including gears, pulleys, sealing rings, and bearings. Our comprehensive design, research, and development capabilities mean we offer personalized customization, tailoring each mold to your specific needs. Serving domestic and international clients, our mold making factories have built a strong global reputation for quality and innovation, revolutionizing industrial functionalities with sustainable, high-performance plastics.

Beyond these techniques, our mold making factories emphasize versatility and environmental responsibility. We produce a diverse range of engineering plastic products that refine operations across sectors, from electronics to heavy machinery. By focusing on electronic injection and injection molding silicone, we ensure that every piece—from enclosures to connectors—meets the highest standards of durability and precision. Our engineers collaborate closely with clients to optimize designs, reducing material waste and enhancing efficiency. As we continue to expand our reach to countries like Canada and beyond, Guangdong Engineering Plastics Industries Group Co., Ltd. remains committed to fostering partnerships that propel your projects forward. Embrace the future of manufacturing with our expert mold making factories, where innovation meets uncompromising quality.