We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, the mould die stands as a cornerstone for creating high-quality components that drive industrial innovation. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting advanced mould dies that integrate seamlessly with processes like rubber injection moulding. Our expertise, backed by a team of senior engineers with 15-25 years of hands-on experience, ensures that every mould die we produce is tailored for optimal performance and durability. Whether you're in the automotive, electronics, or aerospace sectors, our mould dies are designed to meet the rigorous demands of modern production lines, delivering precision and reliability every time.

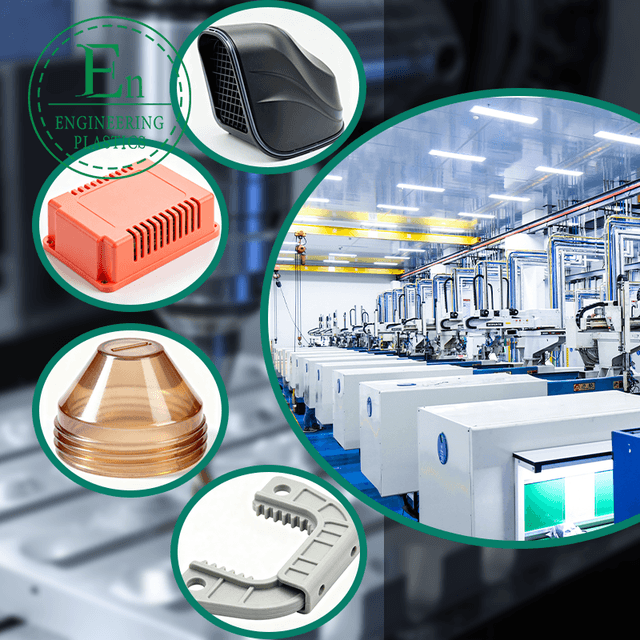

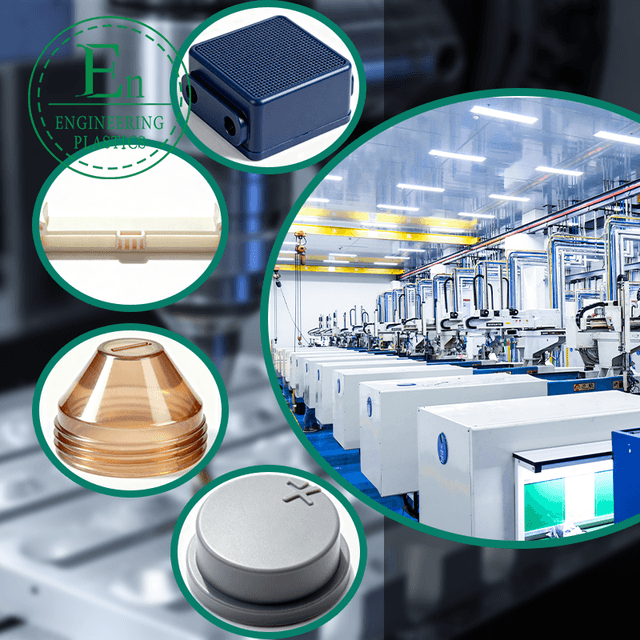

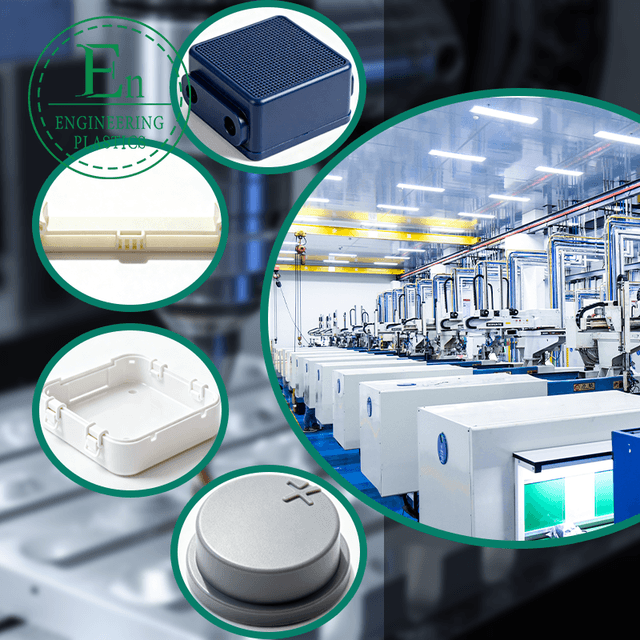

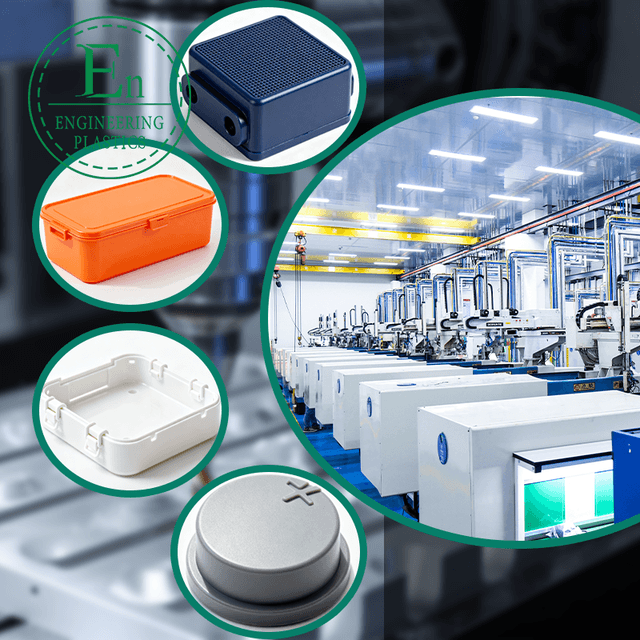

Delving deeper into our offerings, our moulding die solutions are engineered with cutting-edge materials such as PEEK, PPS, Nylon, ABS, and PTFE, which provide exceptional resistance to heat, chemicals, and wear. For instance, in rubber injection moulding applications, our mould dies facilitate the creation of intricate parts like seals, gaskets, and housings with unparalleled accuracy. Take our robust air vent cover, molded using these advanced techniques—its aerodynamic design and sleek black finish enhance air distribution in HVAC systems while ensuring easy installation. Similarly, the vibrant orange housing unit, produced via precise moulding die processes, offers superior protection for sensitive electronics in harsh outdoor environments, showcasing the versatility of our rubber injection moulding capabilities. Our transparent cone nozzle, another highlight, allows for clear fluid flow monitoring and minimal blockages, making it ideal for fluid control systems in various industries.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our commitment to personalized customization and comprehensive R&D services. We don't just manufacture; we collaborate with clients worldwide, from the USA and UK to Canada and Germany, to develop mould dies that align perfectly with specific project needs. Our highly durable jaw clamp, for example, exemplifies this approach—forged through meticulous rubber injection moulding, it provides secure fastening under extreme stress, proving indispensable in mechanical assemblies. By leveraging our state-of-the-art facilities, we ensure that every moulding die undergoes rigorous testing for consistency and quality, reducing downtime and boosting efficiency for our global partners. This global reputation stems from our dedication to innovation, where each product, from gears and pulleys to bearings and sealing rings, is a testament to engineering excellence.

As industries evolve, the role of a reliable mould die becomes even more critical, especially in rubber injection moulding where precision can make or break production outcomes. Our solutions not only enhance manufacturing processes but also contribute to sustainable practices by minimizing material waste through efficient designs. Clients appreciate how our mould dies support scalable production, enabling them to handle everything from small prototypes to large-scale runs without compromising on quality. With exports reaching far beyond Asia, Guangdong Engineering Plastics Industries Group Co., Ltd. continues to empower businesses with tools that foster growth and innovation. If you're seeking a partner for your next project involving mould dies or rubber injection moulding, our team is ready to deliver customized excellence that exceeds expectations. Upgrade your operations today and experience the difference that superior engineering plastics can make in your workflow.