We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of precision manufacturing, the plastic injection die stands as a cornerstone of innovation, enabling the creation of high-quality molded components that drive industries forward. At Guangdong Engineering Plastics Industries Group Co., Ltd., we harness advanced plastic injection die technology to produce engineering plastics that embody durability and meticulous engineering. Our state-of-the-art facility ensures that every plastic injection die is crafted with unparalleled accuracy, meeting the demands of modern applications from automotive to electronics. This process not only guarantees reliability but also opens doors to versatile designs that enhance functionality and aesthetic appeal.

Delving deeper into our offerings, our expertise with the plastic injection die extends to specialized products like cnc mold fabrication, where computer numerical control precision shapes complex geometries with ease. Our senior engineers, boasting 15-25 years of experience, oversee the entire production cycle, from initial design to final output. We utilize premium materials such as PEEK, PPS, Nylon, ABS, and PTFE to create durable items including gears, pulleys, sealing rings, and bearings. The integration of cnc mold techniques allows for rapid prototyping and customization, ensuring that each piece aligns perfectly with client specifications. Whether for domestic needs or international exports to the USA, UK, Canada, Germany, and beyond, our cnc mold solutions deliver consistent quality that has earned us a stellar global reputation.

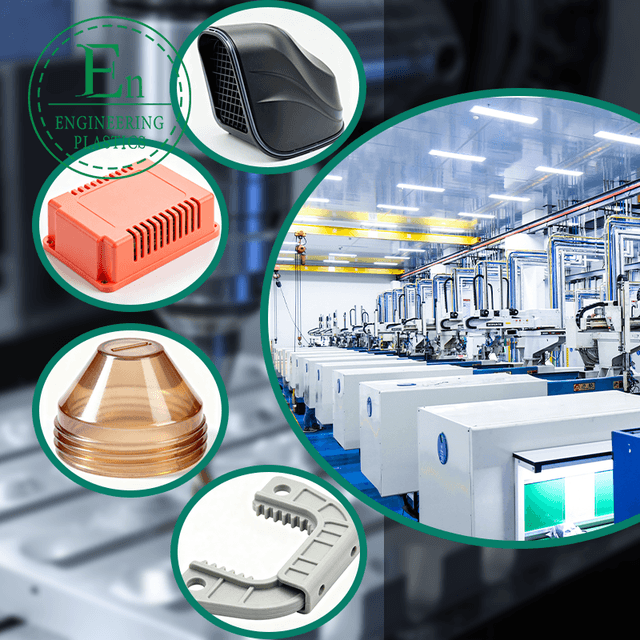

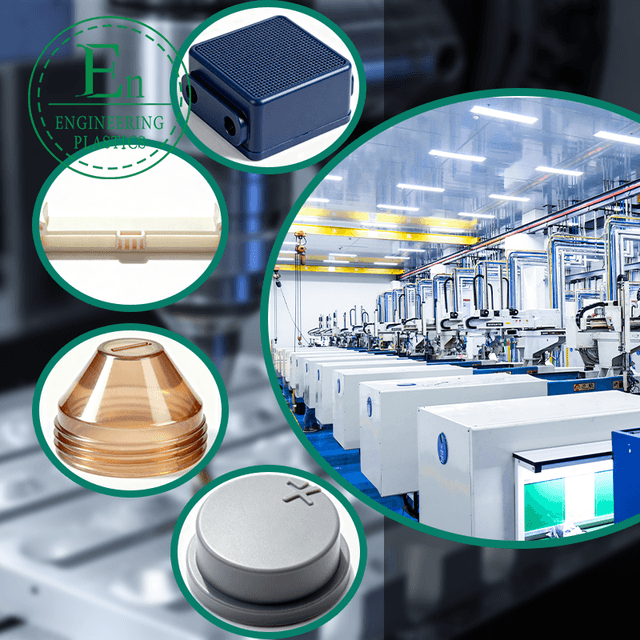

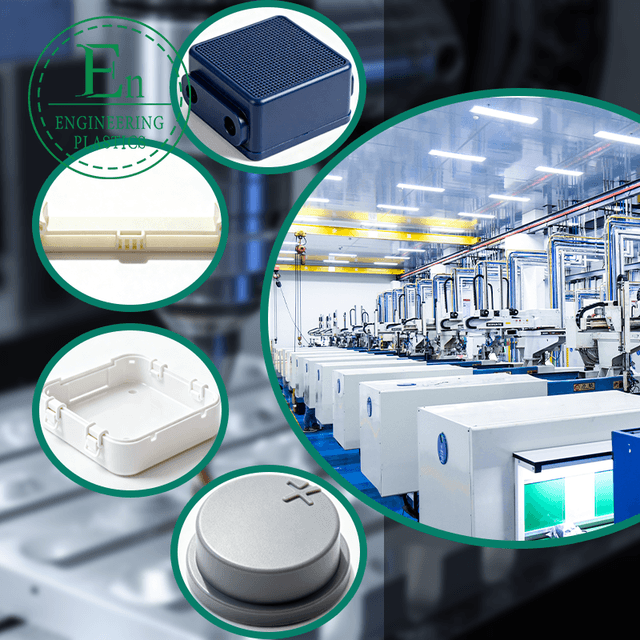

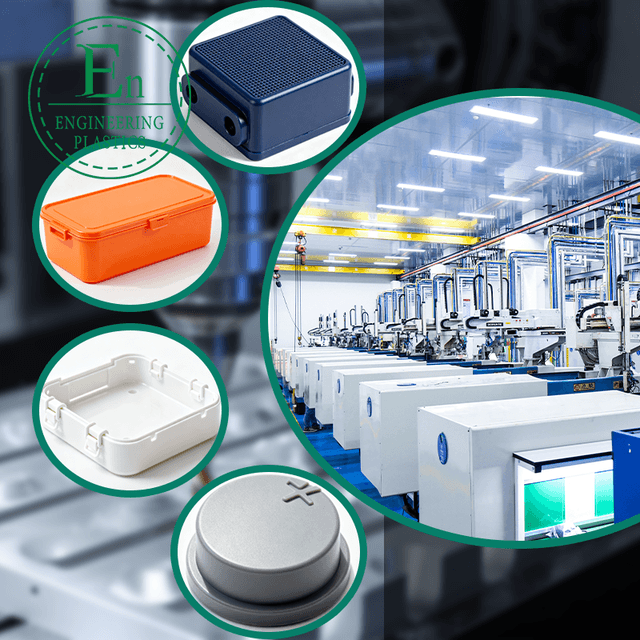

Furthermore, our commitment to excellence shines through in our plastic molds for casting, which complement the plastic injection die process by providing seamless casting capabilities for intricate parts. These plastic molds for casting are engineered in a high-tech environment equipped with automated systems and rigorous testing protocols, minimizing defects and maximizing efficiency. Imagine air vents, translucent shells, and precision fittings emerging from these molds, all designed ergonomically to optimize performance in demanding settings. Our comprehensive research and development capabilities mean we can tailor plastic molds for casting to unique requirements, fostering innovation across sectors. Clients appreciate how our personalized approach transforms concepts into reality, with every detail scrutinized for superior outcomes.

What sets Guangdong Engineering Plastics Industries Group Co., Ltd. apart is our holistic integration of technology and craftsmanship. The plastic injection die isn't just a tool; it's the foundation of our next-generation engineering plastics lineup. By combining cnc mold precision with robust plastic molds for casting, we produce components that withstand harsh conditions while maintaining aesthetic integrity. Our export success underscores the trust placed in us worldwide, as we continue to push boundaries in material science and manufacturing. From concept to delivery, our process exemplifies efficiency, quality control, and customer-centric innovation, inviting industries to embrace the future of molded plastics with confidence.

As we look ahead, the evolution of the plastic injection die promises even greater advancements, and we're at the forefront, ready to collaborate on your next project. With a legacy of serving global markets, Guangdong Engineering Plastics Industries Group Co., Ltd. remains dedicated to delivering solutions that propel progress.