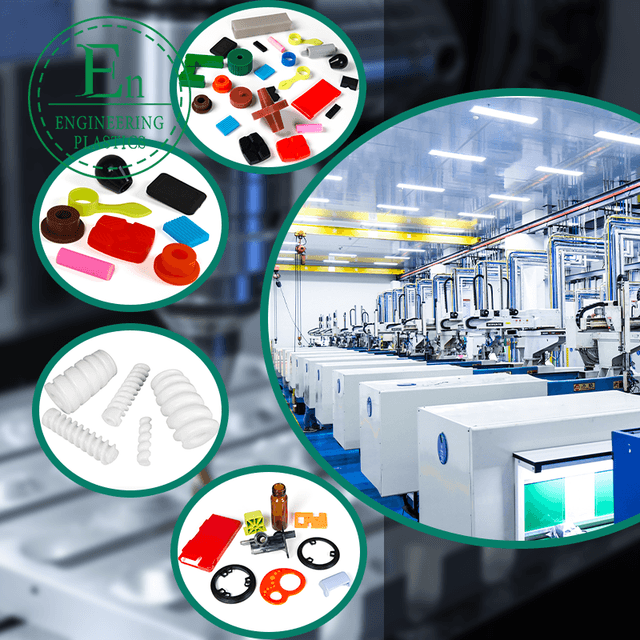

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the competitive world of manufacturing, the pet preform mould stands out as a cornerstone for producing high-quality plastic bottles and containers essential for the beverage and packaging industries. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting these precision-engineered molds that ensure seamless production processes. Our pet preform moulds are designed with advanced technology to deliver exceptional accuracy, durability, and efficiency, making them indispensable for businesses aiming to scale their operations without compromising on quality.

Building on our expertise, our pet preform mould integrates seamlessly with complementary tools like the cap mould, which is vital for creating secure, leak-proof closures for bottled products. With over 15 years of collective experience from our senior engineers, we customize these cap moulds to meet specific client requirements, using premium materials such as Nylon and ABS for superior strength and longevity. This synergy between pet preform mould and cap mould allows manufacturers to produce complete packaging solutions in one streamlined workflow, reducing downtime and enhancing overall productivity. Our state-of-the-art facility in Guangdong employs cutting-edge machinery to fabricate these molds, ensuring they withstand high-pressure injection molding cycles while maintaining intricate details for perfect preform shapes.

Moreover, our portfolio extends to the plastic extrusion mould, which plays a crucial role in shaping continuous profiles for various industrial applications, from automotive parts to consumer goods. Unlike traditional molding techniques, our plastic extrusion mould facilitates the production of uniform, high-volume extrusions with minimal waste, aligning perfectly with sustainable manufacturing goals. At Guangdong Engineering Plastics Industries Group Co., Ltd., we leverage materials like PEEK and PTFE to engineer these molds for extreme temperature resistance and chemical stability, serving clients across the USA, UK, Canada, and Germany. This global reach underscores our commitment to innovation, where each plastic extrusion mould is rigorously tested for precision and reliability, empowering our international partners to achieve superior results in their production lines.

What sets our offerings apart is the personalized approach we take in design and development. Whether it's a pet preform mould for PET bottle production, a cap mould for tamper-evident seals, or a plastic extrusion mould for custom profiles, our team of experts provides end-to-end solutions tailored to your needs. We understand the demands of diverse sectors, from food and beverage to electronics, and our molds are built to handle them all with finesse. By incorporating vibrantly colored options and specialized configurations, we ensure our products not only perform but also enhance the aesthetic appeal of the final goods. Our dedication to quality is backed by comprehensive research and development, resulting in molds that promise longevity and optimal performance, even under challenging environmental conditions.

As we continue to push the boundaries of engineering plastics, Guangdong Engineering Plastics Industries Group Co., Ltd. remains at the forefront, exporting reliable solutions that drive efficiency and innovation worldwide. Investing in our pet preform mould, cap mould, and plastic extrusion mould means partnering with a trusted name that combines decades of expertise with a passion for excellence. Contact us today to explore how our customized molds can transform your manufacturing capabilities and elevate your brand in the global market.