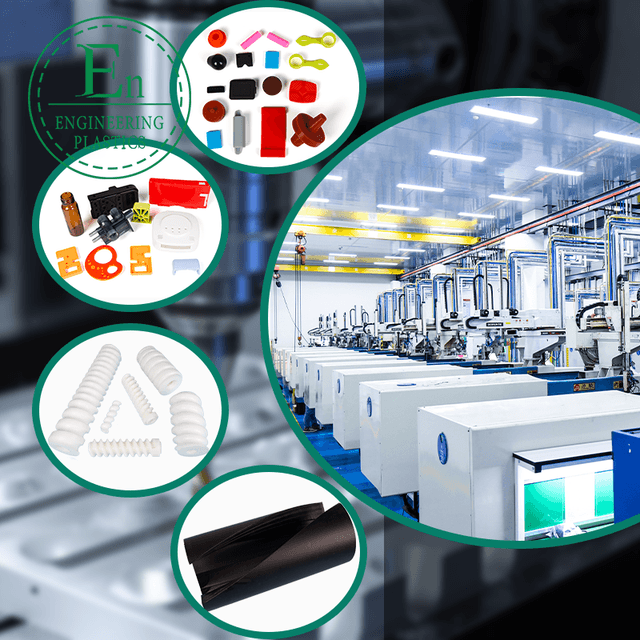

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

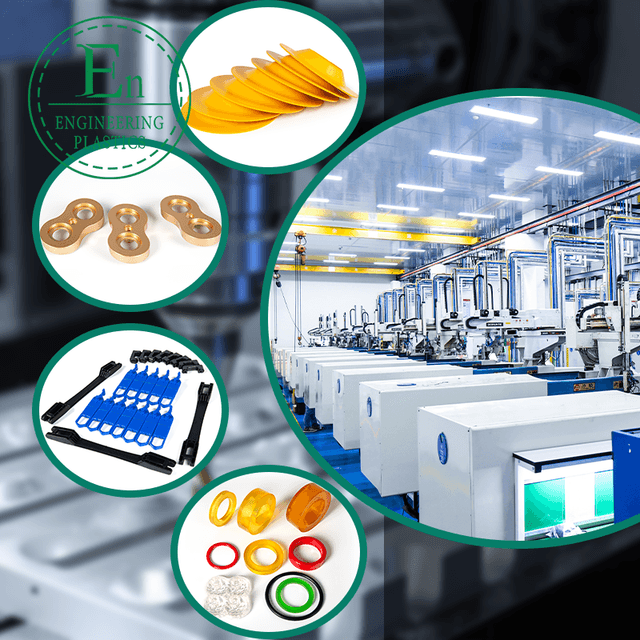

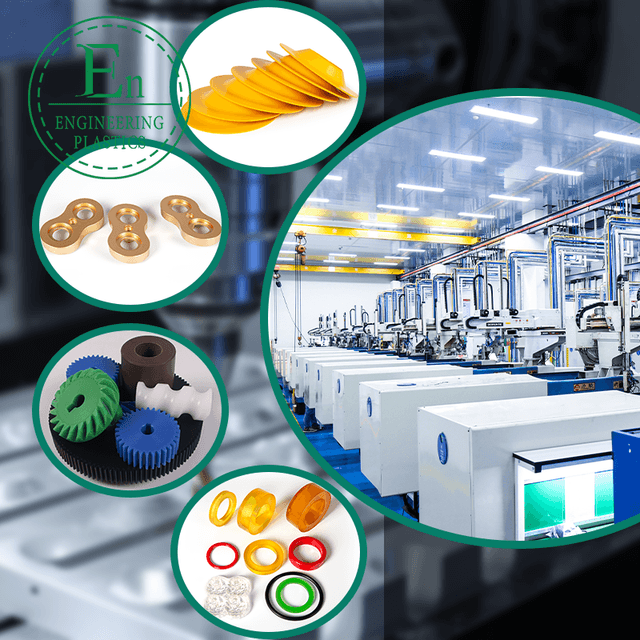

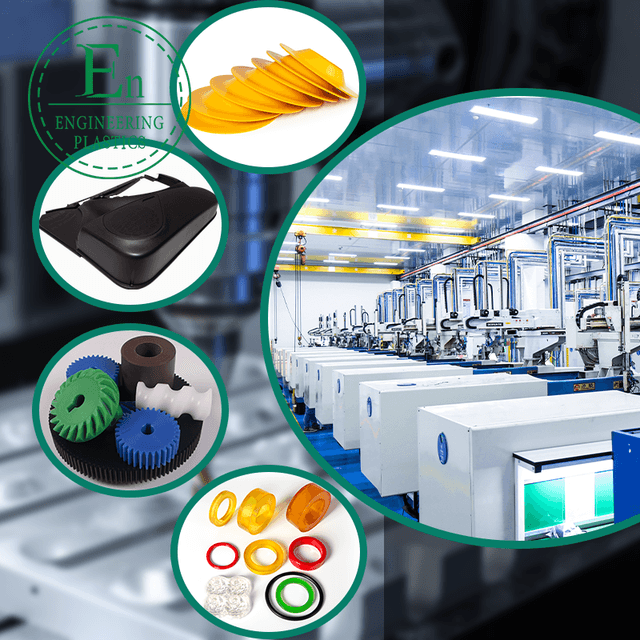

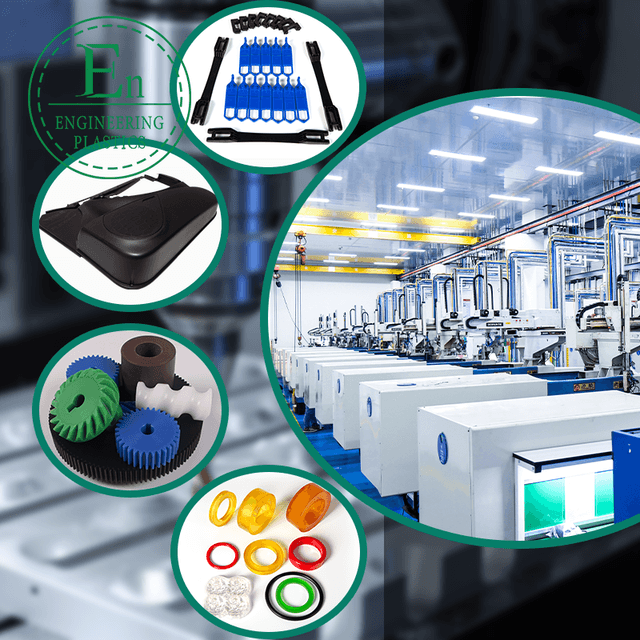

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

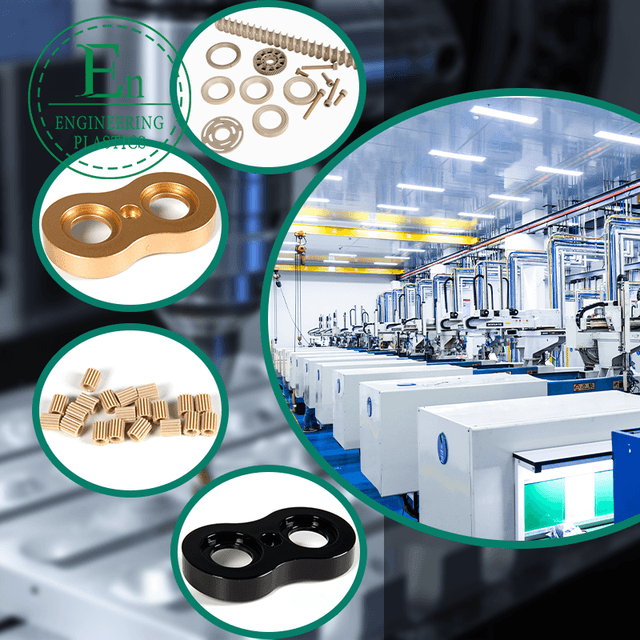

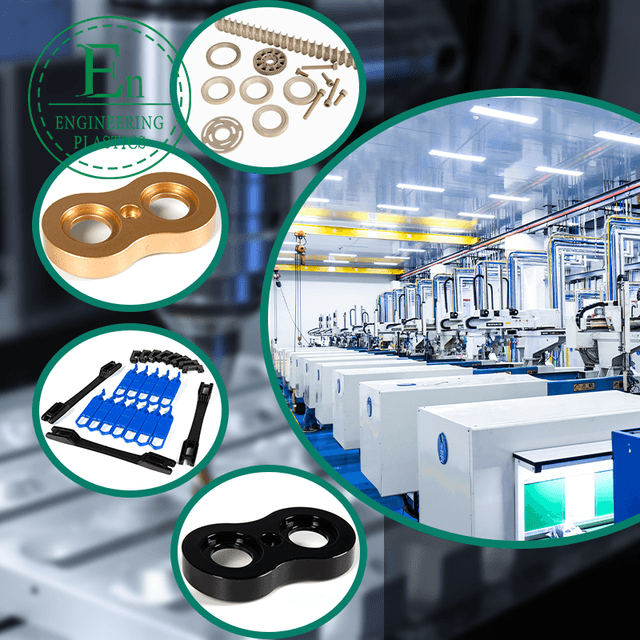

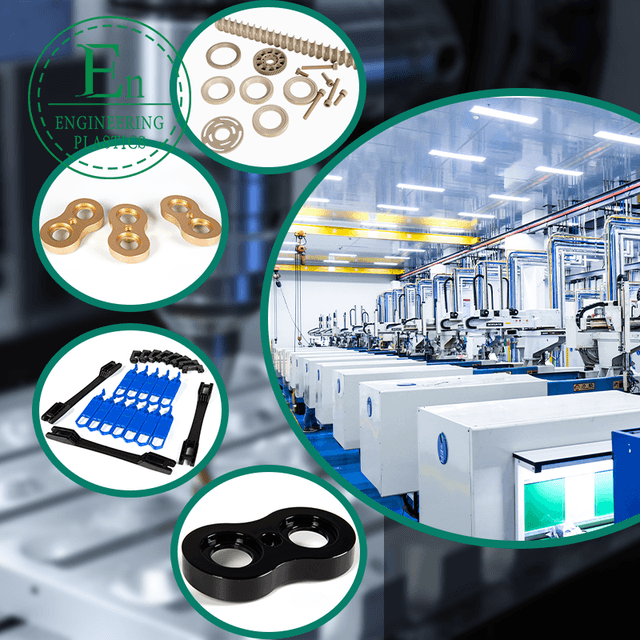

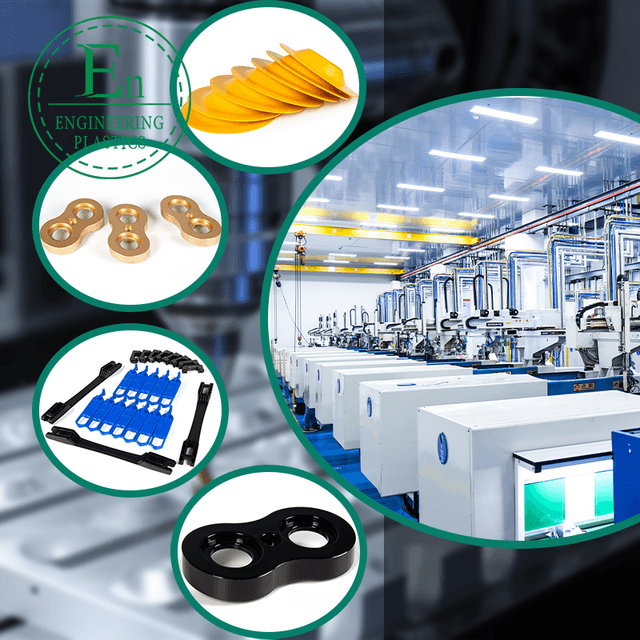

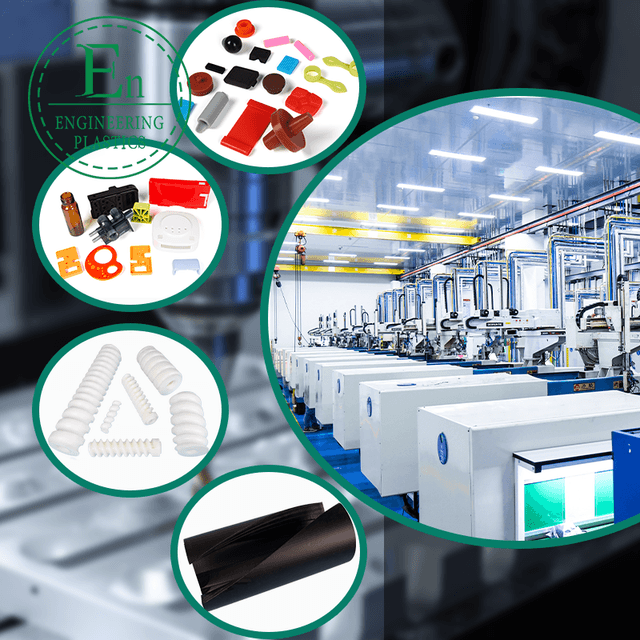

In the world of precision manufacturing, the mini injection mold stands out as a revolutionary tool for creating high-quality, small-scale plastic components. At Guangdong Engineering Plastics Industries Group Co., Ltd., we pride ourselves on delivering innovative solutions that meet the exacting demands of modern industries. Our mini injection molds are engineered for exceptional accuracy, allowing for the production of intricate parts used in electronics, medical devices, and automotive applications. With a focus on efficiency and cost-effectiveness, these molds enable rapid prototyping and small-batch production without compromising on quality.

Our expertise in tools dies extends across a broad spectrum of engineering plastics, ensuring that every project benefits from our 15-25 years of collective experience among our senior engineers. We specialize in designing and manufacturing tools dies that integrate seamlessly with mini injection mold processes, providing durability and precision for complex geometries. Whether you're developing gears, bushings, or connectors, our tools dies are crafted from advanced materials like PEEK, PPS, and Nylon, offering resistance to wear and superior performance in demanding environments. This commitment to customization allows us to tailor solutions that align perfectly with your specific requirements, from initial design to final production.

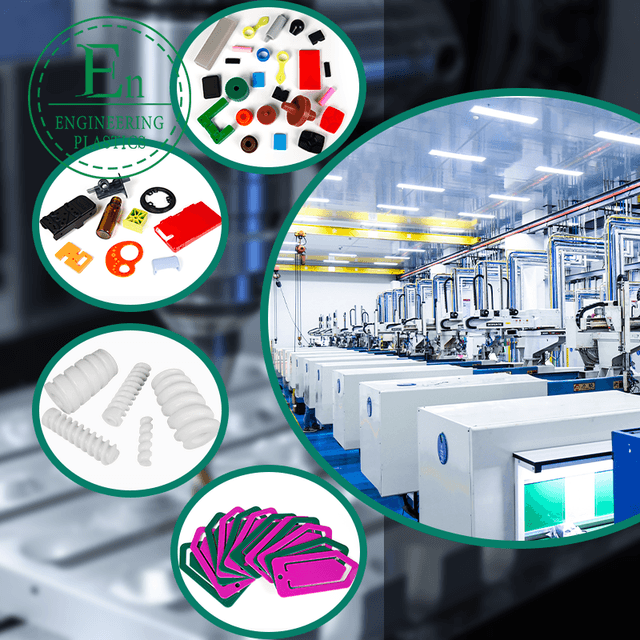

Complementing our core offerings, the pet bottle mold represents another pillar of our versatile product line, ideal for the beverage and packaging sectors. Our pet bottle molds are precision-engineered to produce lightweight, durable bottles with consistent threading and shapes, ensuring leak-proof seals and high-speed manufacturing capabilities. Integrated with mini injection mold technology, these molds support sustainable practices by minimizing material waste and enabling recyclable PET production. Serving clients across the USA, UK, Canada, Germany, and beyond, Guangdong Engineering Plastics Industries Group Co., Ltd. has built a global reputation for reliability and innovation. Our state-of-the-art facility, equipped with cutting-edge machinery, guarantees the highest standards of consistency and quality in every pet bottle mold we produce.

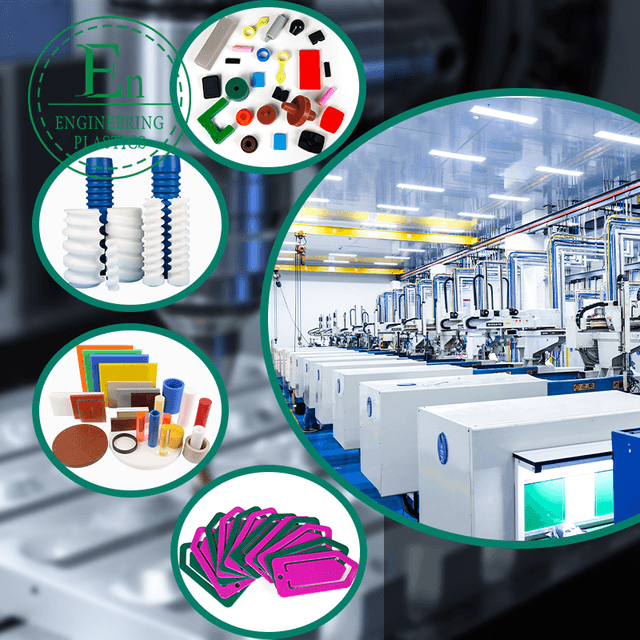

What sets us apart is our holistic approach to polymer engineering, where mini injection mold, tools dies, and pet bottle mold converge to drive efficiency and innovation. Our team collaborates closely with clients to provide comprehensive research and development, from concept to commercialization. Using materials such as ABS and PTFE, we ensure that all components withstand extreme conditions while maintaining aesthetic appeal in finishes like gold and black. This versatility makes our products indispensable for industries seeking robust, long-lasting solutions. As we continue to expand our export markets, our dedication to excellence remains unwavering, empowering businesses worldwide to achieve their production goals with confidence and precision.

Exploring further into our capabilities, the synergy between mini injection mold and specialized tools dies allows for the creation of multifunctional parts that enhance machinery performance. For instance, in the production of sealing rings and bearings, our molds deliver micron-level accuracy, reducing assembly errors and extending operational life. Similarly, our pet bottle mold innovations incorporate advanced cooling systems for faster cycle times, making them a preferred choice for high-volume packaging needs. Backed by our international footprint and proven track record, Guangdong Engineering Plastics Industries Group Co., Ltd. is your trusted partner for all engineering plastic requirements, fostering growth and success in a competitive global landscape.