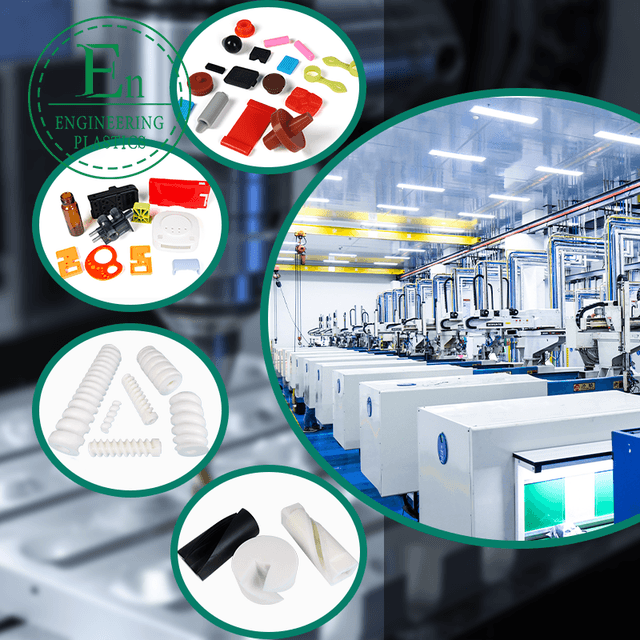

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

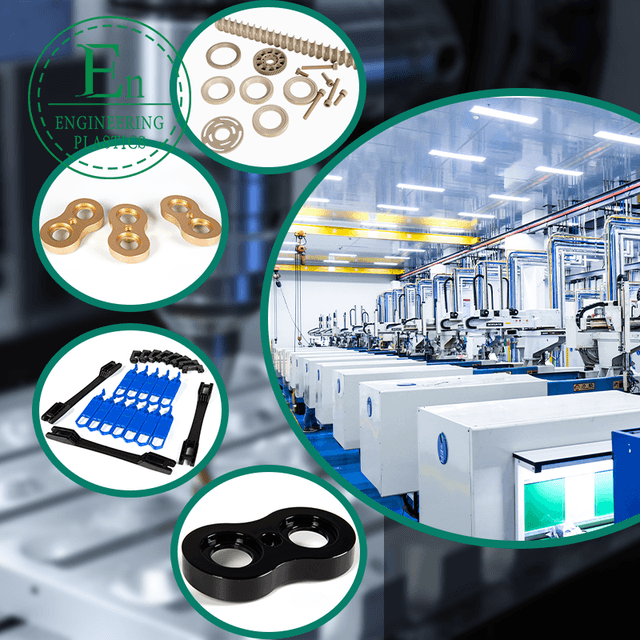

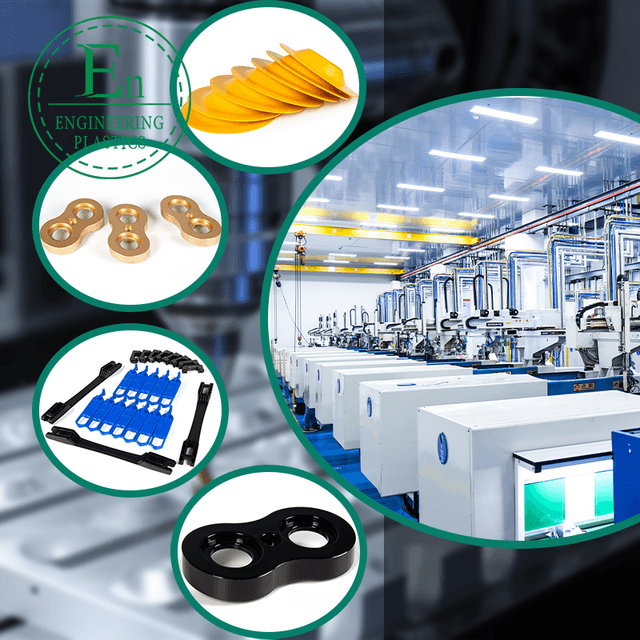

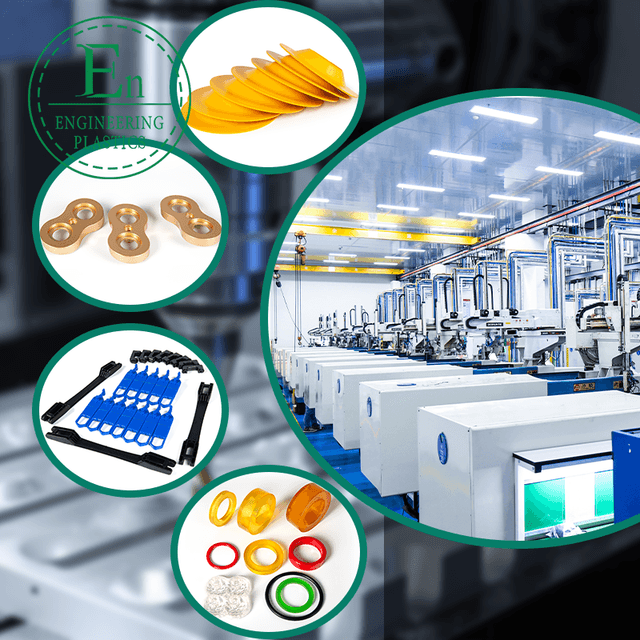

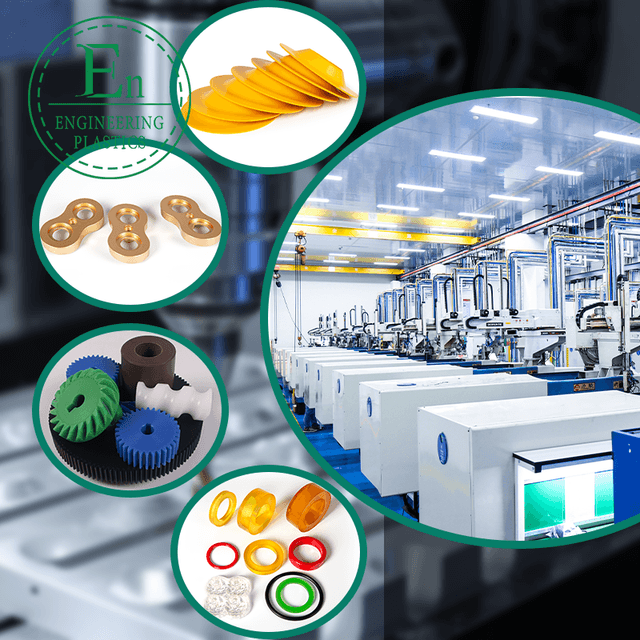

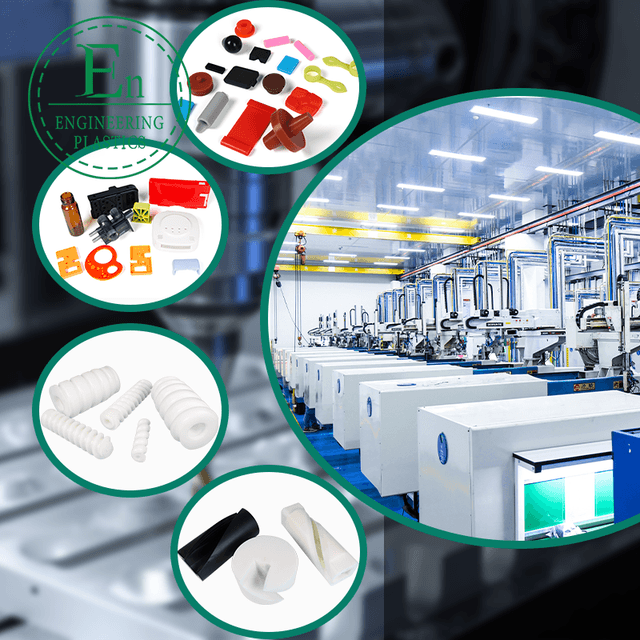

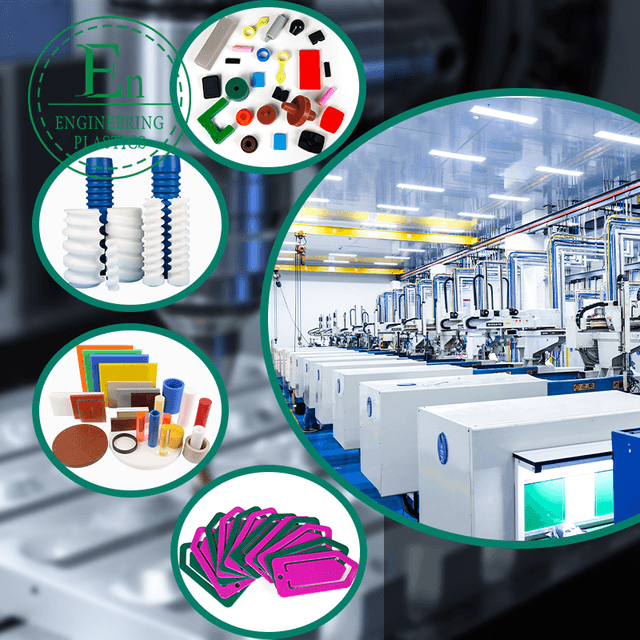

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

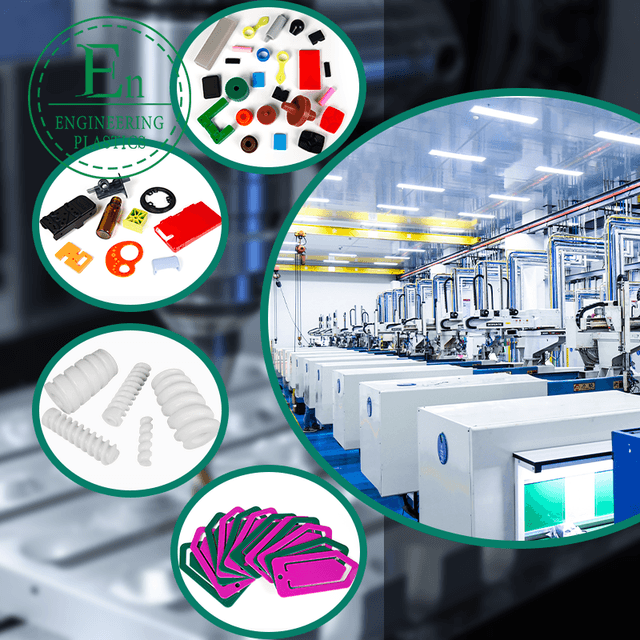

In the world of precision manufacturing, the large injection mold stands as a cornerstone for producing high-volume, durable components across various industries. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting these essential tools with unmatched expertise, leveraging our state-of-the-art facilities to deliver superior results. Our large injection molds are designed to handle complex geometries and large-scale production runs, ensuring efficiency and reliability for our clients worldwide. With a team of senior engineers boasting 15-25 years of experience, we provide personalized customization that aligns perfectly with your project needs, from initial design to final production.

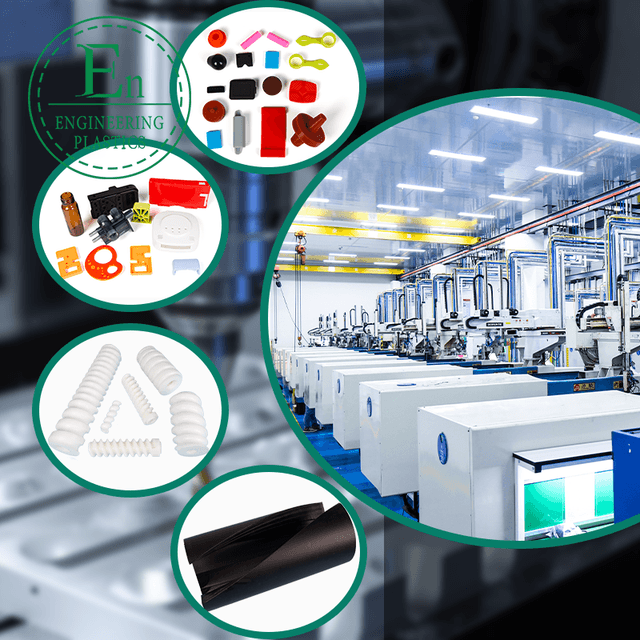

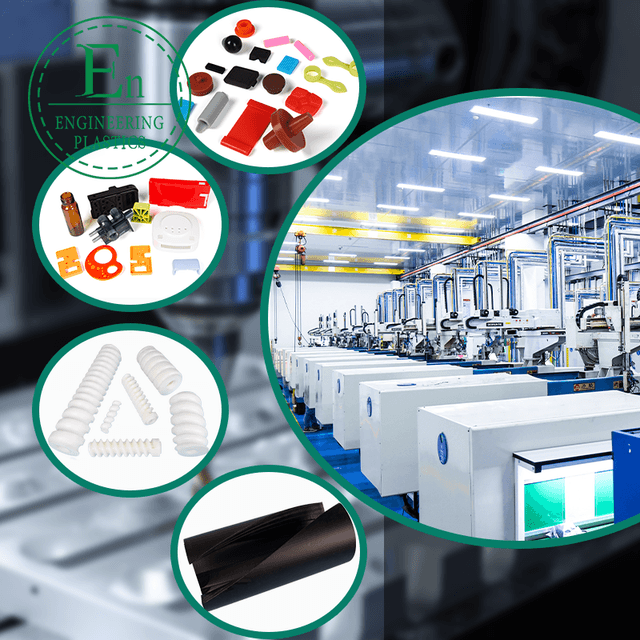

One of our key offerings is the toy mold plastic injection, tailored specifically for the vibrant and imaginative world of toy manufacturing. These molds enable the creation of colorful, intricate plastic parts that meet stringent safety standards while maintaining playful aesthetics. Our toy mold plastic injection processes utilize advanced materials like ABS and Nylon, ensuring the resulting products are both flexible and impact-resistant, ideal for children's toys that endure endless adventures. We take pride in our ability to produce these molds with precise tolerances, minimizing defects and maximizing output. Whether you're developing action figures, building blocks, or educational playsets, our toy mold plastic injection solutions help bring your visions to life with consistency and quality that our international clients in the USA, UK, and beyond have come to trust.

Equally impressive are our chair injection mold designs, which cater to the furniture industry by producing robust seating components that combine comfort, style, and longevity. These molds facilitate the molding of ergonomic chair bases, armrests, and seats using durable engineering plastics such as PPS and PTFE, which offer excellent wear resistance and environmental stability. Our chair injection mold technology supports high-volume production without compromising on detail, allowing manufacturers to create sleek, modern furniture pieces that withstand daily use. By integrating rigorous quality control measures, we ensure every chair injection mold output is free from imperfections, supporting sustainable practices through efficient material usage. Our global reputation for excellence in these areas stems from our comprehensive research and development capabilities, serving clients in Canada, Germany, and more with innovative solutions.

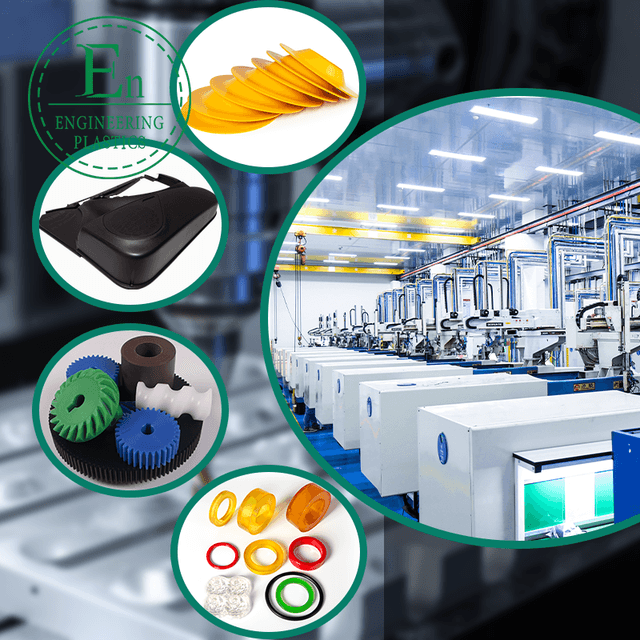

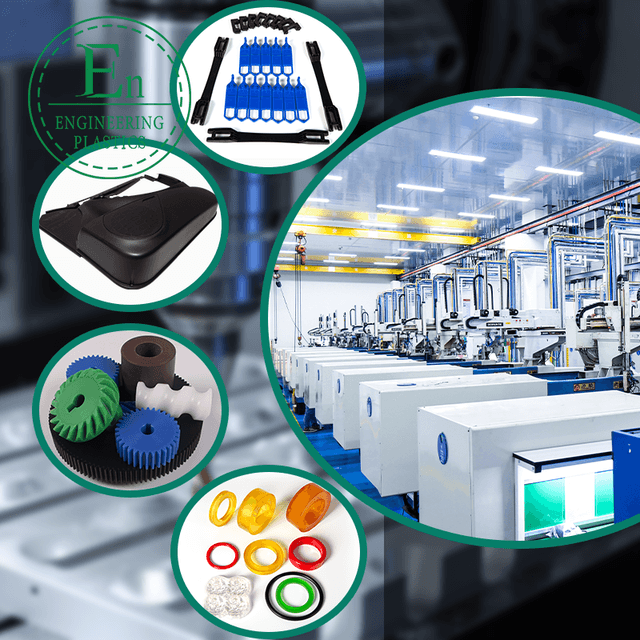

Beyond these specialized applications, our large injection molds encompass a broad spectrum of engineering plastic products, including gears, pulleys, sealing rings, and bearings. We employ cutting-edge injection molding machines to guarantee exceptional consistency, whether producing functional assemblies for automotive parts or specialized fasteners for industrial equipment. Our commitment to innovation is evident in the versatile colorful molded parts and resilient tubing that highlight our portfolio, designed for demanding environments in consumer electronics and beyond. With exports reaching prestigious markets worldwide, Guangdong Engineering Plastics Industries Group Co., Ltd. empowers businesses to innovate confidently. By choosing our large injection molds, you gain a partner dedicated to engineering excellence, where precision meets practicality to drive your success. Our holistic approach, from concept to completion, ensures that every project benefits from our deep industry knowledge and unwavering focus on quality, making us the preferred choice for forward-thinking manufacturers everywhere.