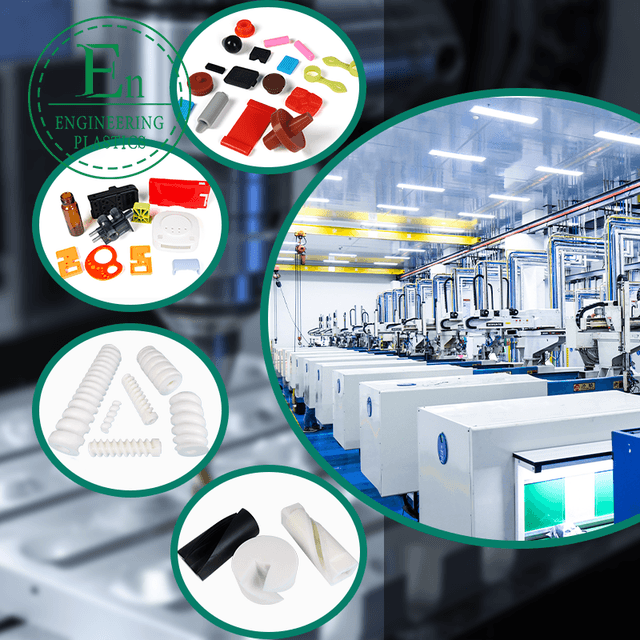

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, medical, automotive, electronics, industrial...

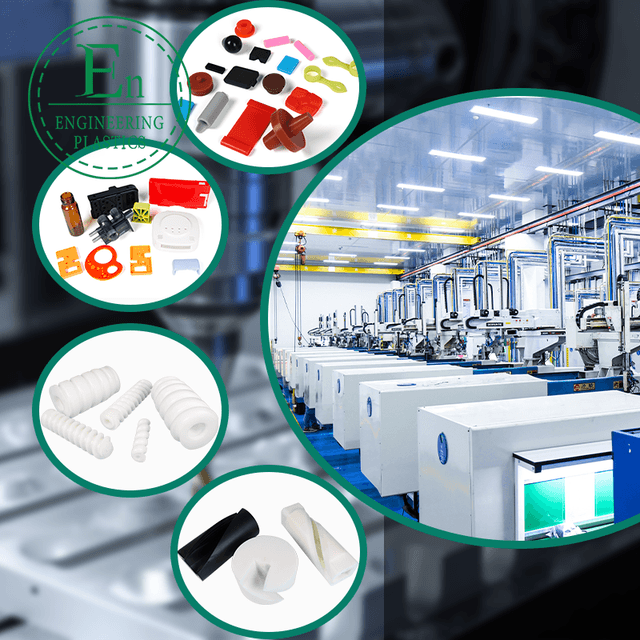

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

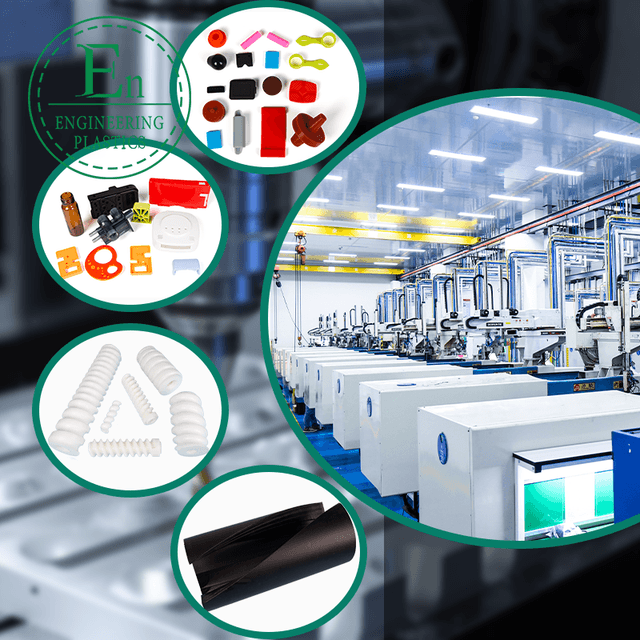

In the world of precision manufacturing, the plastic plate mold stands as a cornerstone for producing high-quality components that drive industrial innovation. At Guangdong Engineering Plastics Industries Group Co., Ltd., we specialize in crafting these essential molds to meet the demanding needs of modern engineering. Our plastic plate molds are engineered with state-of-the-art technology, ensuring unparalleled accuracy and efficiency in production processes. Whether you're developing automotive parts or consumer goods, our molds deliver consistent results that enhance product performance and reduce manufacturing costs.

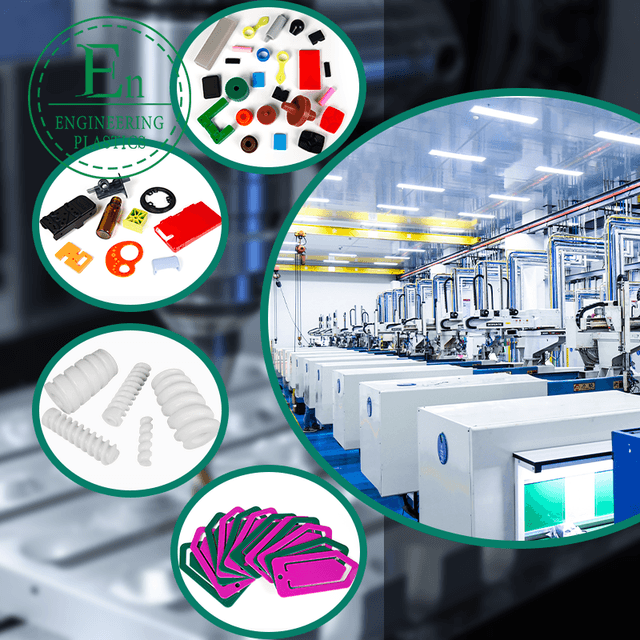

Delving deeper into our offerings, polycarbonate injection molding represents a key technique we employ within our plastic plate mold systems. This process allows for the creation of robust, transparent, and impact-resistant plates that are ideal for applications in electronics, automotive, and medical devices. Our senior engineers, boasting 15-25 years of expertise, customize these molds to handle the unique properties of polycarbonate, resulting in products that withstand extreme temperatures and chemicals without compromising integrity. By integrating polycarbonate injection molding into our plastic plate mold designs, we provide clients with versatile solutions that streamline assembly lines and boost output quality. Furthermore, our facility's advanced capabilities ensure that every mold adheres to international standards, making it a trusted choice for global manufacturers.

Complementing our core expertise, bumper molding is another specialized area where our plastic plate molds excel. These molds are meticulously designed to produce durable bumper components for vehicles, leveraging materials like ABS and Nylon for superior impact absorption and aesthetic appeal. At Guangdong Engineering Plastics Industries Group Co., Ltd., we understand the rigorous requirements of the automotive sector, which is why our bumper molding processes incorporate precision engineering to minimize defects and maximize longevity. Clients from the USA, UK, Canada, and Germany have relied on our exports for years, praising the reliability of our plastic plate molds in high-volume production runs. This not only enhances vehicle safety but also contributes to sustainable manufacturing by reducing material waste through optimized mold designs.

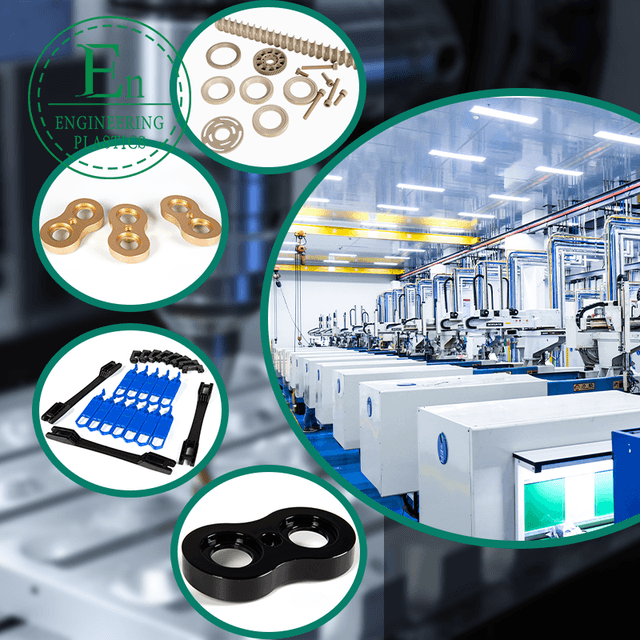

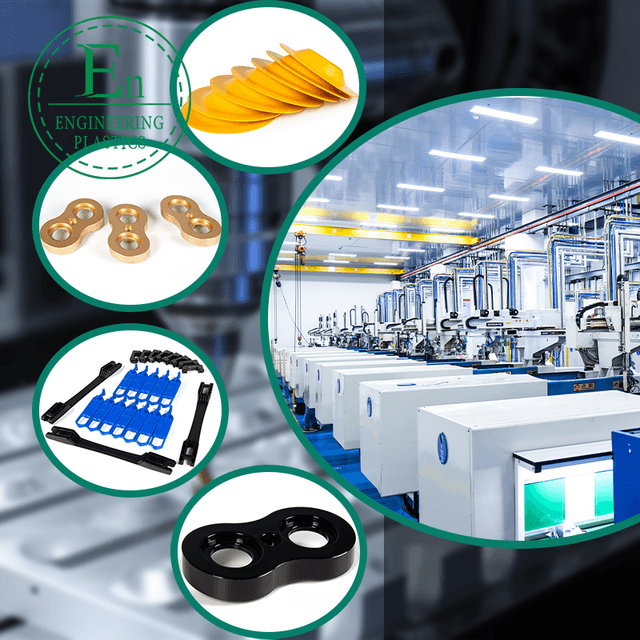

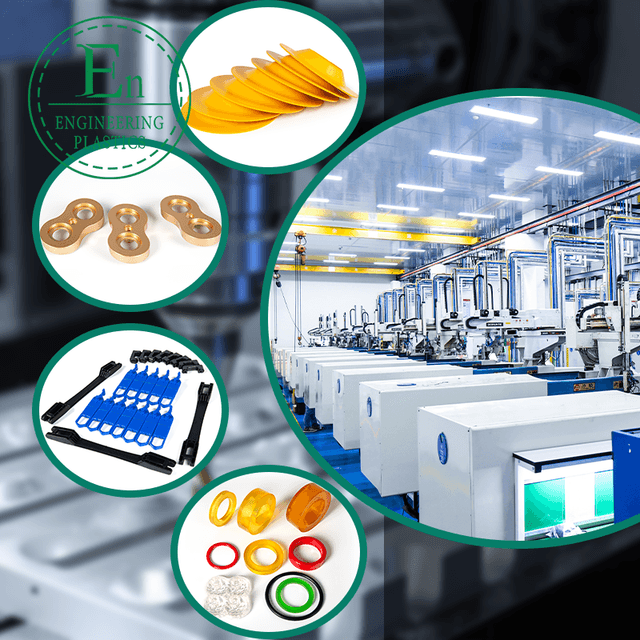

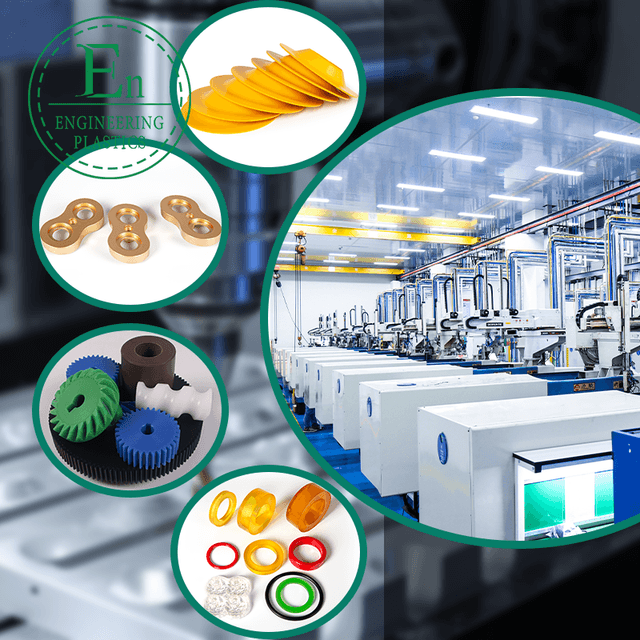

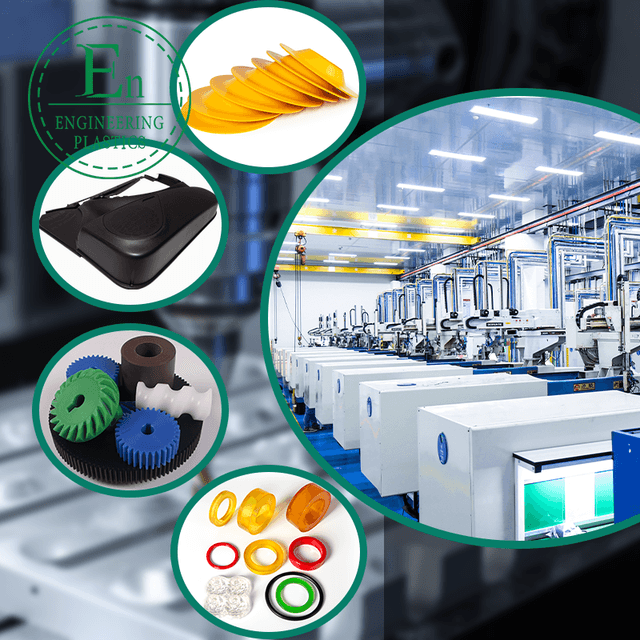

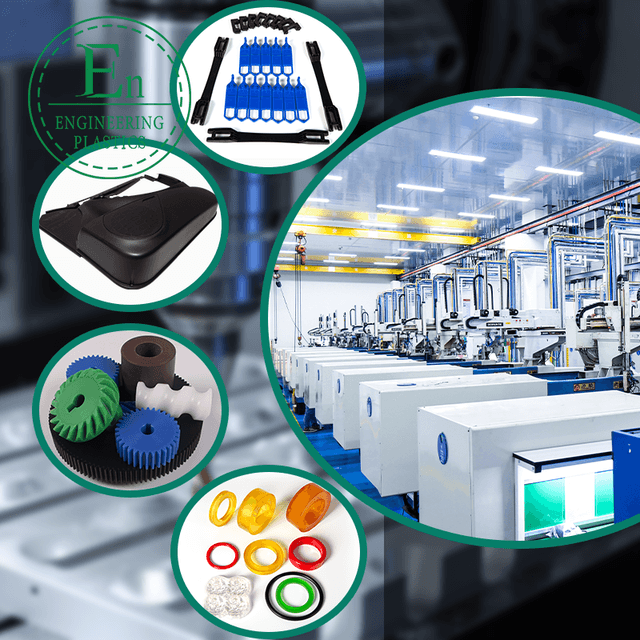

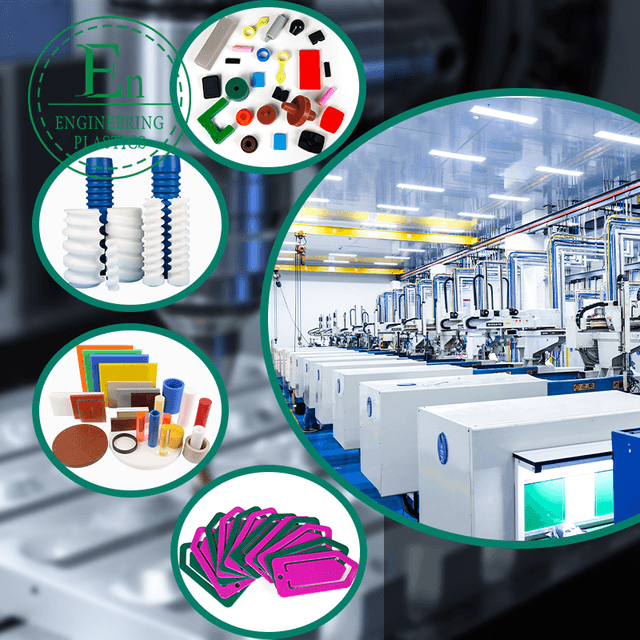

Our commitment to innovation extends beyond standard applications, as we offer comprehensive design, research, and development services tailored to your specific needs. From gears and pulleys to sealing rings and bearings, our plastic plate molds support a broad spectrum of engineering plastic products made from advanced materials like PEEK, PPS, and PTFE. Imagine seamless integration of polycarbonate injection molding for lightweight yet strong plates, or bumper molding for reinforced automotive exteriors—all produced under one roof in our state-of-the-art facility. This holistic approach ensures that your projects benefit from our global reputation for excellence, with personalized customization that aligns perfectly with your brand's goals.

As we continue to serve domestic and international markets, Guangdong Engineering Plastics Industries Group Co., Ltd. remains dedicated to pushing the boundaries of what's possible with plastic plate molds. Our yellow discs offer exceptional wear resistance in high-friction settings, while bronze-colored components provide robust load-bearing strength for mechanical systems. For electrical applications, our blue and black insulation connectors guarantee secure, insulated connections in harsh environments. And our sleek black components exemplify versatile integration into diverse assemblies. With every product crafted to the highest standards, we invite you to experience the transformative power of our engineering plastics. Partner with us to elevate your manufacturing capabilities and achieve superior results that stand the test of time.